Exposure to toxic or highly-potent powders is a challenge for the industry and for those responsible for safety in the workplace.

Isolation containment solutions and safe transfer systems do not cover all the eventualities of exposure to these products. In particular, an operator may be subject to possible accidental exposure to toxic dusts during the production process or during maintenance or cleaning work that may be conducted in these environments.

As good practice in these cases, a risk analysis would detail each and every one of the possible occurrences of exposure to toxic dust. From this analysis, it will be possible to mitigate most of the risk with product and process containment systems and, sometimes, with personal protection measures.

It should be said that there is always a risk of exposure to operators when they undress and remove personal protection equipment (PPE) items.

In fact, even when considering strict compliance with production procedures and the use of PPE, it is still very difficult to ensure that operator clothing does not retain any toxic product particles.

In addition, there will always be maintenance or cleaning tasks, in which the risk of product exposure will be greater. And it is in precisely these cases where the utmost attention must be given to minimise possible exposure when the operator is removing their PPE and clothing.

To reduce the previously described risk, Albian Group has developed a decontamination shower fog for dust encapsulation.

These shower pods, built in a self-supporting format, are designed for easy installation in contamination controlled environments, particularly in the exit changing rooms of those zones.

Fog-based encapsulation

The operating principle of this equipment is based on reducing the dust from the powders being processed by encapsulating it with a fog formed of droplets in a size range of between 5–10µm.

The innovation is that this fine fog enters the shower pod at a very low speed, avoiding the generation of turbulence when the dust has not yet been encapsulated.

With previous systems, dust deposited on the operator's suit was removed by the effect of an air spray system or air shower.

This new shower is a fully automated system with a PLC and an easy operation touch screen for the control of decontamination cycles, and is integrated seamlessly into pharmaceutical enclosure finishes.

It also features an internal pressure control system, enabling it to integrate into the pressure cascade configuration of the containment zone.

This shower pod provides an information system for a better understanding of the equipment's operating status. It uses coloured lights inside the shower pod enabling the decontamination cycle to be interpreted by the occupant.

The interior structure of the equipment is constructed in AISI 304 stainless steel with an exterior finish of acrylic stone.

Its 4 + 4 laminated safety glass doors have a built-in inflatable seal.

Above: Gasket inflated seal doors are designed to ensure containment

This equipment model must be connected to an external ventilation system to allow for programmed ventilation and pressurisation processes.

In-built CIP

The equipment also features a CIP system for cleaning the equipment after each cycle.

The CIP system can also be equipped with a safe filter change at the extraction level, if not contained in the installation to which it is connected.

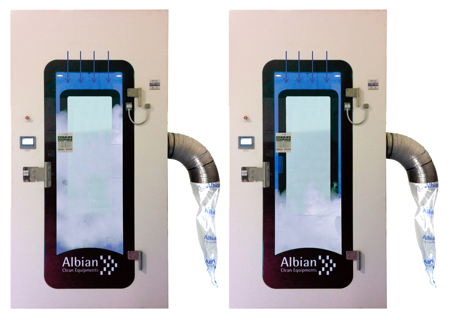

The equipment has an internal CIP system

The operational phases of this decontamination shower model are:

- Standby: In this position the shower is available for use. During this phase the inflatable seal doors are closed and the seals inflated, to maintain containment.

- Entry Phase: After pressing on the entry touch screen, the operator enters the shower and closes the door from the inside.

- Encapsulation Phase: once the operator is inside the shower, fog is then injected at low speed until the environment has been saturated and the dust encapsulated.

- Undressing Phase: During the first part of this phase, a laminar flow is put into operation to vertically remove (from top-bottom), the fog present in the shower pod. Once the fog has disappeared the user begins to undress; the dust is encapsulated and sticks to the suit (no dust is left in the cabin), and under a laminar flow the operator is in the safest possible environment for undressing Once the operator has removed his clothing, it is deposited in the waste outlet of the shower, which has an adjoining containment bag.

- Output Phase: Having deposited their clothes the operator moves into the safe area by the second door of the shower pod.

- CIP: After the encapsulation process, the CIP cycle can be activated to clean the inside of the pod and the extraction ducts.

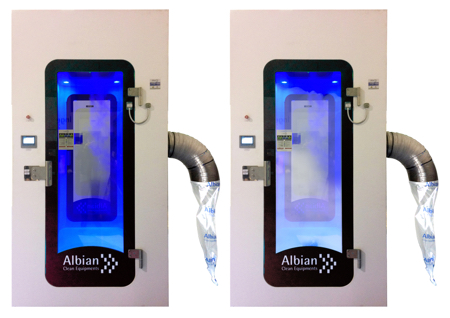

Different stages of the low turbulent fog injection that is initiated to encapsulate the dust

Ensuring operator safety

During the production of highly potent toxic products, there are a number of devices and procedures to ensure operator safety; however, the exit and undressing stage is one of the most critical. Potentially, the most dangerous stage occurs when removing clothes and PPE, because toxic dust may be on the operator’s clothing and PPE and come into contact with the operator.

To avoid the latter, there is the option of encapsulating the dust or powder, and removing it through a specially developed shower fog.

This fog or mist enters the shower pod at low speed to avoid creating turbulence or moving any dust before it is encapsulated.

On completion of the encapsulation, a laminar flow is activated to protect the operator by vertically removing the fog, enabling them to remove their clothing and PPE as safely as possible.

Bibliography

1. Albian Clean Equipments. Shower RLM-750-PT. www.albian.es

2. NTP (Technical Prevention Notes) 798: Pharmaceutical industry: Preventive Measures for exposure to active products.

3. English (HSE) Health and Safety Executive - Health and Safety Commission - HSC - advisory committee on toxic substance (HSG 193)

4. US Occupational Safety & Health Administration – OSHA