China-based modular cleanroom expert Airkey has supplied an ISO Class 4 FastIns Ultra-clean Modular Cleanroom for semiconductor research and production in Mexico.

The cleanroom is made of prefabricated sandwich panels and high-tempered glass windows, creating flush and seamless mounting. It ensures a clear and bright working environment that is convenient for visiting and showing.

To reach ISO Class 4, a double ceiling and raised floor are designed to create actual laminar flow. The grilled raised floors allow for efficient air return to save energy and precisely maintain the temperature, humidity and pressure inside the cleanroom.

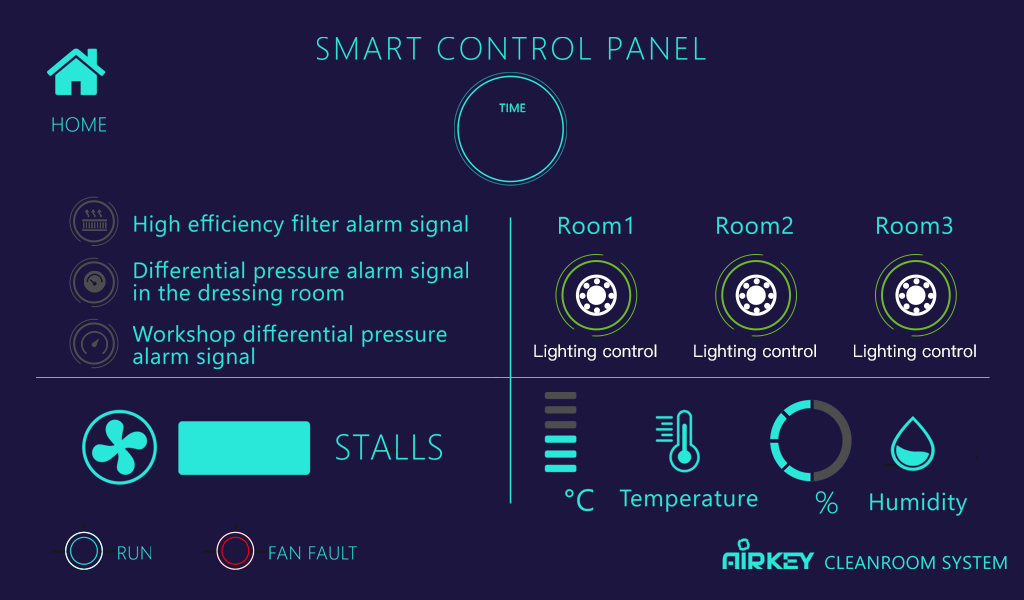

The cleanroom has 118 fan filter units (FFUs), centrally controlled by a touch screen, which can display and control the cleanroom parameters conveniently, including temperature and humidity.

The specifications of this project:

- Area: 135 sqm

- Inner height: 4.55m

- Class: ISO Class 4

- Design temperature/RH: 22-26℃/45-65%

- Industry: Semiconductor

- Location: Mexico

While AI is growing more advanced all over the world, the semiconductor industry keeps expanding to support AI development.

Airkey capabilities

Airkey has been dedicated to creating sterile and dust-free space for pharmaceutical-related companies in accordance with GMP, USP, ISO14644 and other regulations.

Additionally, Airkey fabricates all the components in the factory to make lego-like installation possible, facilitating the installation process in customer’s location. For an area of 135 sqm, only two weeks are needed for installation, real fast installation.