This cleanroom requires an area of 84 square meters in ISO 8 class (Class 100,000) for 3D printing, to be delivered to Italy. Our customer is engaged in 3D printing, which has gained more popularity in recent years as technologies advance. A cleanroom is essential to control the work process of 3D printing since the presence of even the tiniest particles can cause contamination and affect the precision of the end products. To create and maintain a clean and controlled environment, they require an ISO 8 cleanroom with an area of 84 square meters.

One of the unique features of this cleanroom is the free-standing structure. This cleanroom is 10x8m, a large span, yet the customer does not want any posts or suspension to their roof. As a result, Airkey engineers designed and produced the cleanroom with trusses to further stabilize the cleanroom, freeing it from posts or suspension.

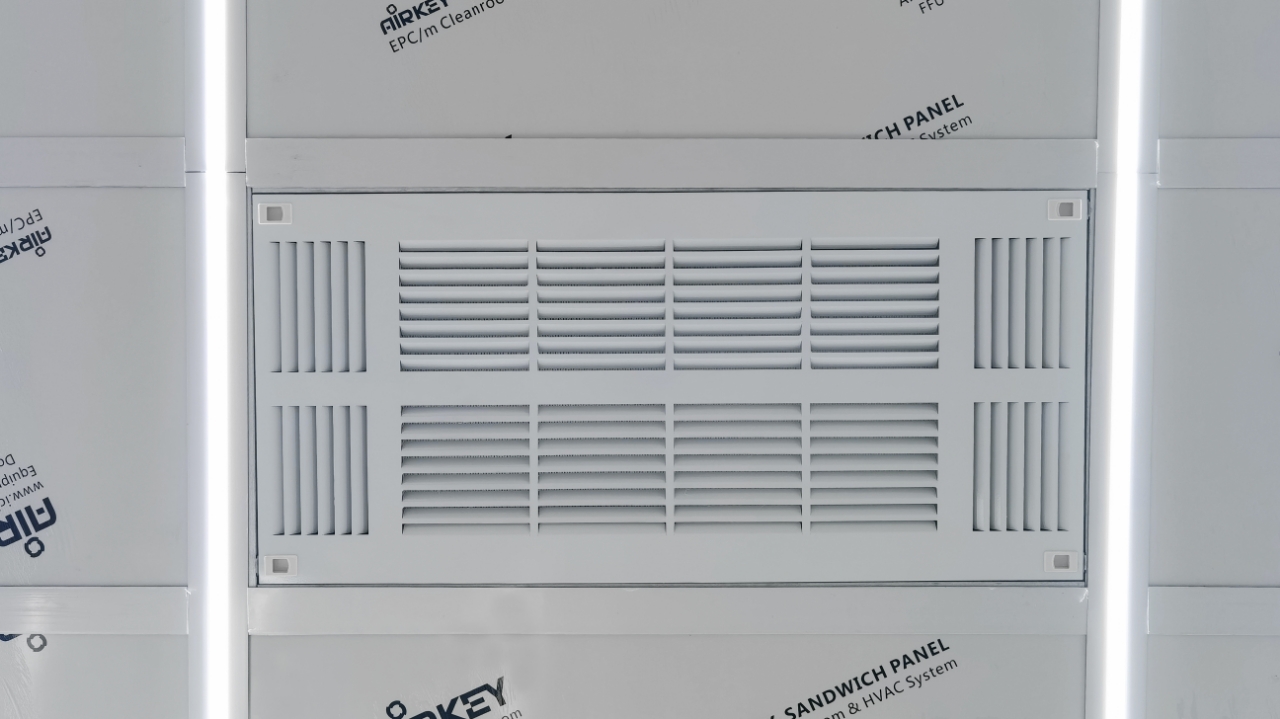

In addition, the cleanroom is equipped with an aircon unit that can control the temperature to maintain a comfortable environment for the workers. The cassette-type aircon unit is easy to install. Recirculating filter units (RFUs), our new patented products, are installed to recycle the clean and cool air, saving energy and providing a greener solution to cleanroom construction.

Other features are reflected in the details, including automatic sliding doors for quicker transfer of large materials, European-standard power outlets at designated locations, installation brackets for aircon units, and the continuous arrangement of windows for visiting customers.

If you want to learn more about Airkey cleanrooms, feel free to visit our website: www.airkeyx.com.

The specifications of this project:

- Project: 3D Printing Modular Cleanroom

- Area: 84 m²

- Inner height: 2.6 m

- Class: ISO 8 (Class 100,000)

- Design temperature/RH: 18–22°C

- Industry: 3D Printing

- Location: Italy

For more details about Airkey products, www.airkeyx.com