Airkey understands that a cleanroom is not just an isolated box, but a dynamic ecosystem tailored to a specific manufacturing process. A recent project for a forward-thinking manufacturer in New Zealand exemplifies this philosophy. Airkey designed and delivered a bespoke, modular cleanroom dedicated to injection moulding, ensuring the production of high-integrity plastic components free from environmental contaminants.

Client challenge & design philosophy

The client required a controlled ISO 8 environment to house injection moulding machines, protecting the process from airborne particulates that could affect product quality, surface finish, and consistency. Key challenges included accommodating the substantial height of the moulding machinery and seamlessly integrating the cleanroom into an existing factory layout while maintaining operational workflow efficiency.

Airkey’s design philosophy was clear: the cleanroom must adapt to the process, not the other way around.

Tailored solution: a modular ecosystem for moulding

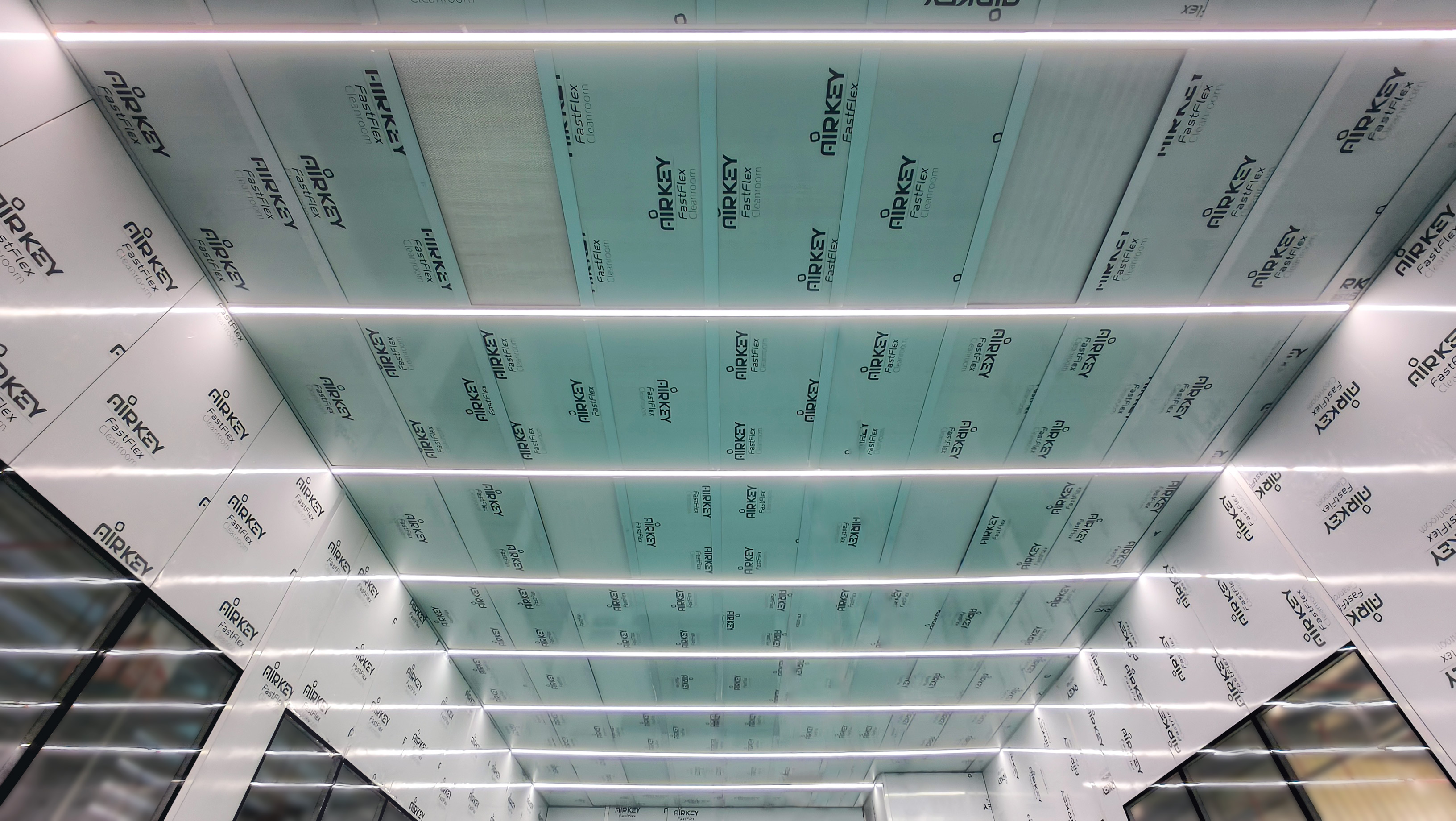

Airkey engineered a free-standing, modular cleanroom measuring 10.6 m (L) × 5.7 m (W) × 4 m (H). The 4-metre ceiling height was specifically calculated based on the client’s machine profiles, ensuring optimal operational space and efficient airflow management.

Process-centric design: The layout was configured around the material and personnel flow inherent to injection moulding. Raw materials enter through one side, and finished goods exit another, creating a logical and contaminant-controlled workflow.

Dual-control panels for unmatched convenience: To support operational flexibility, two control panels were installed—one at the entrance and another inside the cleanroom. This allows technicians to adjust environmental parameters, such as fan speed, without exiting the controlled area, streamlining process tuning and maintenance.

Harmonious factory integration: The cleanroom features double-tempered glass windows that are flush-mounted and precisely aligned in size and location with the building’s existing windows. This creates a visually cohesive workspace while allowing natural light to flood the interior, improving the operator environment and reducing reliance on artificial lighting.

Advanced contamination control logistics

A cleanroom’s effectiveness depends on its airlocks and transfer systems. Airkey implemented a multi-tiered approach:

- Personnel air shower: with interlocked doors to remove particles from clothing before entry.

- Pass-through box: allowing finished goods to be transferred out of the cleanroom without compromising the internal environment.

- High-throughput cargo air shower: equipped with roll-up doors to facilitate the quick and convenient delivery of raw material pallets or carts into the cleanroom. This design significantly accelerates replenishment compared to standard pass boxes.

Core construction & environmental control

Constructed with a robust aluminium alloy frame and insulated sandwich panels, the cleanroom structure delivers durability and excellent thermal performance. The cleanroom achieves and maintains ISO 8 (Class 100,000) cleanliness, ensuring positive pressure and appropriate air changes per hour to protect the sensitive moulding process.

To learn how Airkey’s ISO-certified modular cleanrooms can enhance production quality and efficiency, visit www.airkeyx.com

.