Suitable applications for disposable cleanroom clothing may include the following:

- For use in remote or difficult to access locations.

- When very low numbers of cleanroom garments are required.

- When cleanroom clothing is worn infrequently.

- When heavy staining with oils, greases, paints and inks would make decontamination of reusable clothing impossible.

- Where garments may be contaminated with harmful biological, chemical or radioactive substances.

- As disposable clothing for staff during the cleaning and commissioning phases of new builds.

- For use as a back-up for re-usable garments; especially to accommodate visitors, contractors and new starters.

- When it is necessary to have cleanroom clothing which is also required to act as Personal Protective Equipment (PPE) for the wearer and to be CE marked. This is often the case for bulk active pharmaceutical ingredient (API) manufacturing when specific chemical repellency is needed.

- To provide the best contamination control option e.g. cleanroom gloves.

Non-woven fabrics

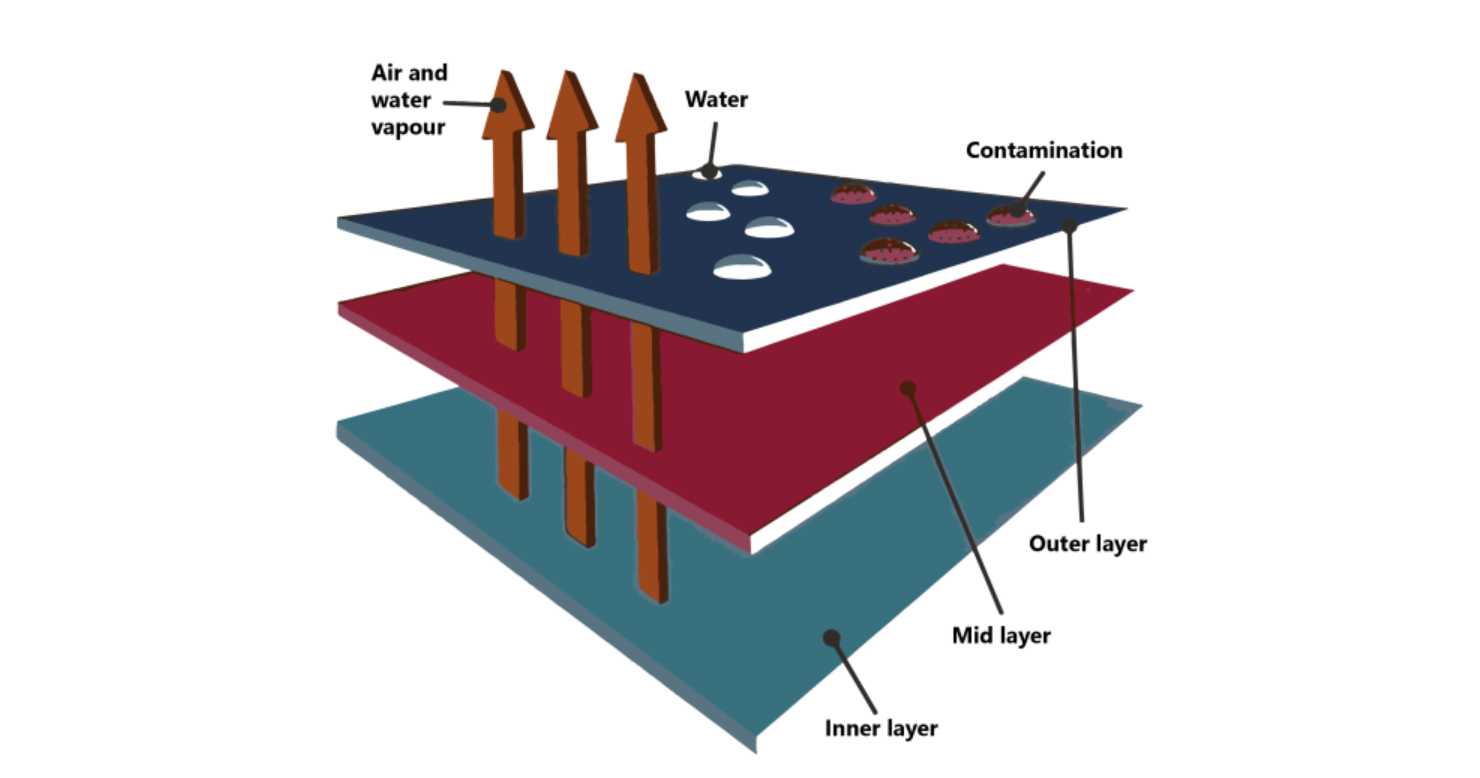

The fabrics used to produce disposable cleanroom garments are not produced by a weaving process and are therefore referred to as non-woven fabrics. Non-woven fabrics are produced using spunlaid techniques from plastic polymers such as Polypropylene, Nylon and Polyester.

Filaments of the material are extruded then drawn and laid on a moving screen, called a web former, to form a filament web.

The filament web can be made into a finished fabric by the application of heat and pressure without the need for additional binding agents.

Fabrics produced in this way are usually referred to as spunbonded non-woven fabrics.

Variations in the method of producing the filaments have been developed to produce non-woven fabrics with different characteristics.

Meltblown non-wovens are produced by using a spunlaid technique which extrudes and draws molten polymer resins with heated, high velocity air to form much finer filaments. The filaments are again cooled and collected as a web onto a web former before being made into a finished fabric.

Flashspun fabrics are produced by a further variation of spunlaid technology; a solution of polymer and solvent is extruded under conditions which produce rapid solvent evaporation; this causes the extruded filaments to split further into a highly intricate and fine web which is again collected onto a web former before being made into the final fabric.

Laminated non-woven fabrics are also available and produced from layers of different materials glued together to produce different characteristics of strength and permeability.

There are many different types and brands of non-wovens available but the most commonly recognised brand is TYVEKTM which is a registered trademark (DuPont).

Disposable clothing for use as Personal Protective Equipment (PPE)

When a risk assessment has identified that a specific cleanroom task requires the use of PPE then disposable garments which are CE marked to confirm suitability for the task must be chosen. The clothing must also be compatible with the contamination control requirement of the area of use.

European directives1 require that all PPE must be certified according to category I, II or III.

Category I clothing is identified as simple design with minor risk which can be identified by the user, Garments are labelled with a CE mark only.

Category II describes all PPE except those in category I or III. Garments are labelled with a CE mark only.

Category III garments are identified as complex design and intend to protect the wearer from risk of serious or fatal injury which may not be identified by the wearer in sufficient time. Category III garments are labelled with the CE mark plus a four digit code of the relevant notified body.

In addition the garment type indicates the kind of protection offered by protective clothing as defined by European Standards.2

Category III PPE includes six types:

- Type 1 – Gas-tight clothing

- Type 2 – Non gas-tight clothing

- Type 3 – Protection against pressurised liquid chemicals

- Type 4 – Protection against liquid aerosols

- Type 5 – Protection against airborne solid particulate chemicals

- Type 6 – Limited protection against mist

It is important to note that if disposable garments are required for PPE then advice must be obtained from a Health and Safety professional to confirm the correct choice of clothing.

When disposing of contaminated items after use, safe and acceptable disposable procedures must be identified and used.

For more information on Micronclean's Disposable Contamination Clothing, click here.

References

- Personal Protective Equipment Directive 89/686/EEC.

- BS EN 943-1:2002. Protective clothing against liquid and gaseous chemicals, aerosols and solid particles. Performance requirements for ventilated and non-ventilated “gas-tight” (Type 1) and “non-gas-tight” (Type 2) chemical protective suits. Note this has been replaced by BS EN 943-1:2015+A1:2019: Protective clothing against dangerous solid, liquid and gaseous chemicals, including liquid and solid aerosols.