You can picture a room that deals with medical substances or even food testing. Lab coats and chemicals are not far off. It's a space in which having any additional germs or particles, like dust, could impact what is being researched or controlled in the room. Cleanrooms are particularly used in fields like pharmaceuticals, medical device production, in hospitals or food testing. The goal with cleanrooms is to keep them as clean as possible. This is largely done through cleanroom air filters. If you are unfamiliar with these filters, this article will provide a clear explanation.

Cleanrooms are actually a thriving and growing market. The global cleanroom technology market was valued at approximately USD 4.1 billion in 2023 and is projected to reach over USD 7.2 billion by 2033, with a CAGR of around 4.8%1. Selecting the right air filters plays an essential role in keeping this technology operational and maintaining the cleanliness of cleanrooms. Did you know that airflow velocity ranges from 40 ft/min for an ISO 5 room to 100 ft/min for an ISO 1 room? This means that airflow is a major impact of cleanrooms. If you'd like to learn more about this, keep reading.

Where clean air begins and why particle capture sets the standard

The efficiency of a cleanroom air filter is largely determined by its ability to capture particles. In cleanrooms, you’re not just filtering dust you can see. You’re dealing with microscopic particles that can compromise sterility, product quality or patient safety. Let’s clarify with an example: A typical office space has between 500,000 and 1 million particles per cubic foot (equivalent to an ISO 9 cleanroom), whereas an ISO 5 cleanroom allows only 100 particles per cubic foot2.

You see, filters are often rated based on their ability to capture particles of a specific size. The smaller the particle, the harder it is to trap. High-efficiency filters are designed to capture particles that are far smaller than the width of a human hair.

Several factors influence particle capture performance. First, you have to look at the density and structure of the filter media. Then, you need to understand the size of particles the filter is designed to trap. Plus, it's vital that you look at the depth of the filter material and the airflow speed passing through the filter.

A highly efficient cleanroom filter balances strong particle capture with consistent airflow, ensuring contaminants are removed without disrupting the environment.

Inside the filter: how materials and design shape performance

The material used inside the filter plays a massive role in how efficient it is. Filter media isn’t just a sheet of fabric. It’s an engineered material designed to trap particles through diffusion, interception and impaction.

Higher-quality media tend to have a more uniform fiber structure, maintain performance over long periods, resist damage from airflow pressure and handle moisture and chemical exposure better.

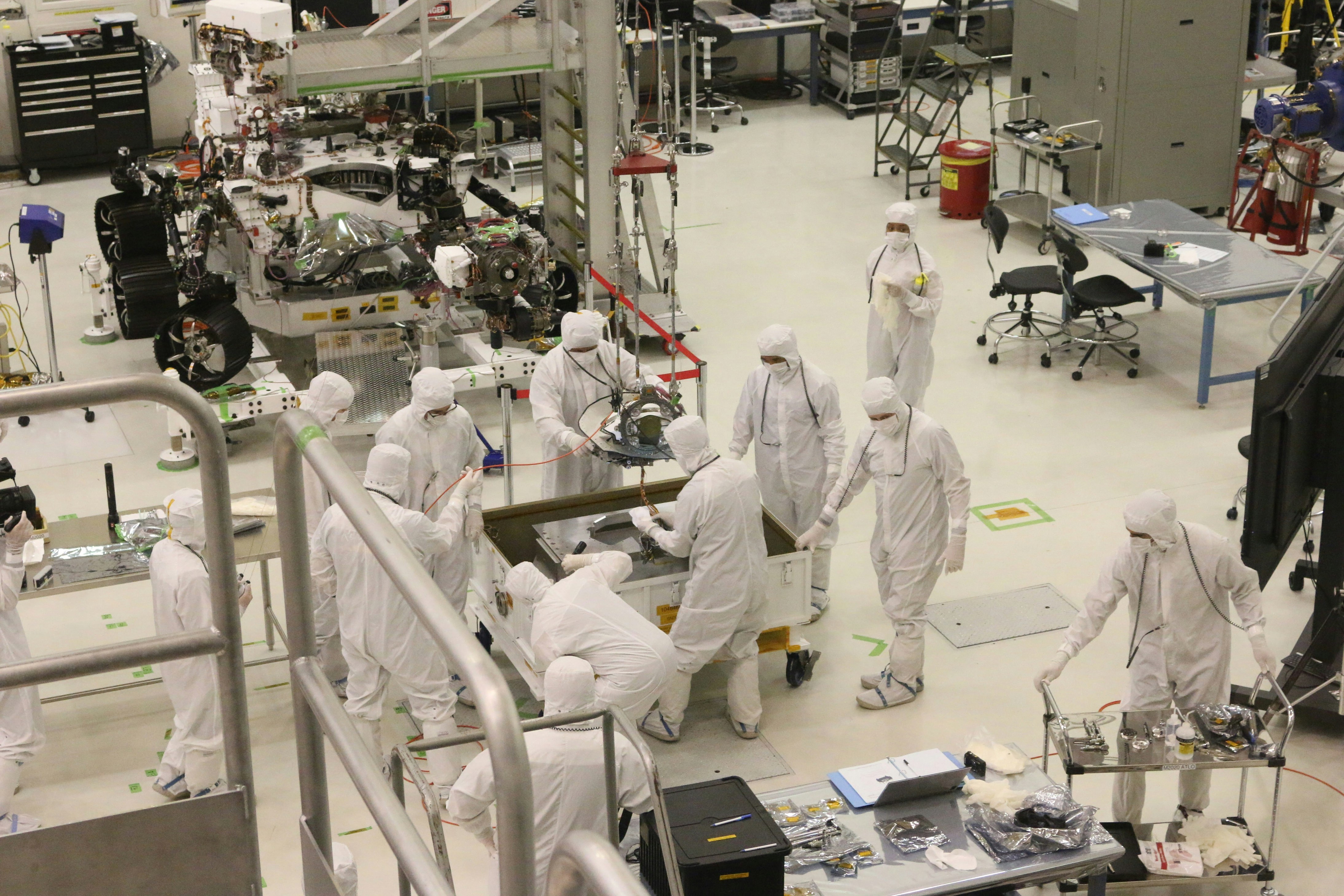

The way the medium is folded or layered also matters. Pleated designs increase surface area, allowing more particles to be captured without restricting airflow too much. Well-constructed cleanroom filters can operate efficiently for longer before they need replacement. Such designs are generally more effective than standard filters. As maintaining sterility in cleanrooms is challenging, optimal filter performance is crucial. Did you know that human operators are the number one cause of contamination? Yes, they're responsible for an estimated 70% to 80% of contamination problems3. Using high-quality filters helps mitigate the risks associated with human contamination, which remains a leading cause of cleanroom issues.

The balancing act of airflow speed, resistance and real efficiency

Efficiency isn’t just about how much a filter catches. It’s also about how air moves through it. If the airflow is too fast, particles can slip through. If it’s too slow, the system may not circulate air effectively. Pressure drop refers to the resistance air encounters when passing through a filter. As a filter loads with particles, resistance increases. A highly efficient filter manages this balance by trapping contaminants while keeping pressure drop within acceptable limits.

Things that influence airflow performance include:

- Filter thickness and surface area

- Media density

- Fan power and system design

- Cleanroom air change requirements

An efficient filter supports stable airflow, helping maintain consistent temperature, humidity and cleanliness levels.

Small gaps lead to big problems: why installation quality can’t be ignored

Even the best cleanroom air filter loses efficiency if it isn’t installed correctly. Gaps, poor seals or misalignment allow unfiltered air to bypass the filter entirely. This is known as leakage and it’s one of the most common causes of reduced cleanroom performance.

Proper installation technology ensures all incoming air passes through the filter, no contamination enters through cracks or gaps and airflow patterns remain predictable and controlled.

Ceiling-mounted systems, filter fan units and modular housings all rely on tight sealing to perform as designed. Attention to detail during installation often makes the difference between theoretical efficiency and real-world results.

Matching filters to cleanroom purpose with understanding in mind

Efficiency is also defined by what the cleanroom is used for. A cleanroom producing medical devices has different air quality needs than one manufacturing pharmaceuticals or housing surgical theaters. This is only normal because each product that is being produced or each vial that is being inspected has its own standards. Furthermore, each application determines required air change rates, maximum allowable particle counts, filter type and grade and redundancy as well as safety margins.

An efficient filter is one that meets the specific demands of the environment without overengineering the system. Too much filtration can increase energy use and costs, while too little can compromise safety and compliance. It's about finding the right balance.

Efficiency over time and why maintenance is just as important as design

Even the most advanced filter doesn’t stay efficient forever. Over time, particles build up, airflow resistance increases and performance begins to drop. Regular monitoring and maintenance are essential to keep efficiency high.

Good maintenance practices include monitoring pressure drop levels, replacing filters before performance declines, inspecting seals and housings, verifying airflow and particle counts and keeping records for compliance and audits. This just means that you have to be as consistent as possible. Efficiency isn’t just about initial performance. It’s about consistency over time. This can't be something that you look at once a month. Daily monitoring is recommended to ensure the cleanroom remains safe and well-controlled. Cleanrooms require consistent maintenance and monitoring to operate effectively. Keeping detailed records of environmental conditions allows for timely adjustments and continuous improvement.

When the environment pushes back: heat, humidity and chemical stress

Temperature, humidity and chemical exposure all influence how well a filter performs. High humidity can affect filter media, while certain chemicals may degrade materials over time. An efficient cleanroom air filter is designed to handle controlled humidity levels, reduce overall pollution, temperature fluctuations within set limits, exposure to disinfectants or sterilizing agents and continuous operation without breakdown. Matching filter materials to the cleanroom environment helps prevent premature failure and performance loss. Managing changes in environmental conditions can be complex and may significantly affect cleanroom cleanliness. This is why cleanrooms often go through multiple checks a year to ensure that their level of cleanliness is as high as it can be.

How system design elevates air quality and why integration is key

A filter doesn’t operate in isolation. Its efficiency depends on how well it integrates with the rest of the cleanroom system. Fans, ducts, diffusers and control systems all affect how air moves and how contaminants are removed. Although system control can appear challenging at first, it becomes more manageable as familiarity increases.

A well-designed system ensures even air distribution across the cleanroom, minimal turbulence and dead zones, predictable airflow patterns and efficient use of energy. When all components work together, the filter can perform at its highest potential. Proper integration is essential for the system to function optimally.

Why efficiency matters more than ever and should be on your radar

Cleanroom efficiency isn’t just a technical concern. It directly impacts safety, quality and trust. In healthcare, pharmaceutical production and advanced manufacturing, a single contamination event can have serious consequences.

Efficient air filtration helps:

- Protect patients and staff

- Safeguard sensitive products

- Meet regulatory standards

- Reduce operational risk

- Improve long-term reliability

Efficiency focuses on prevention by creating an environment that proactively reduces the likelihood of problems.

How all the pieces of the cleanroom puzzle efficiently come together

The efficiency of a cleanroom air filter is shaped by a combination of design, materials, installation and ongoing care. It’s the way all these elements come together that defines how well a filter protects a cleanroom environment.

When you look at cleanroom air filtration through this lens, it becomes clear why careful selection and maintenance matter so much. An efficient filter doesn’t just clean air. It supports safety, consistency and confidence in some of the most critical environments around.