The financial considerations when selecting a laboratory or research grade autoclave fall into two basic categories: the initial purchase price and actual running costs. The latter is often the greatest concern as organisations strive to lower utility costs, reducing electrical consumption and water usage.

As most manufacturers produce a range of laboratory autoclave types to meet many differing applications it is important to understand the sterilising requirement of the laboratory in terms of load variation and frequency. This can influence a decision as to whether an autoclave with a cylindrical or rectangular chamber is the best choice.

Where higher daily throughputs are required many might opt for a rectangular chamber. Straight sides mean more items can be loaded into the sterilising chamber; from wall to wall and top to bottom. Its performance, however, is the key. Is the rectangular chamber design more efficient when fully loaded? Does it provide effective sterilisation? And what is the overall cost of ownership?

The design matters

A rectangular pressure chamber is not a natural fit for steam sterilisation; it is a poor thermal vessel and by its very nature a pressure vessel wants to be round (see figure 1).

During the average sterilisation cycle, tremendous forces strain every joint, corner and seam of the pressure vessel as the steam works to turn that box into a sphere. To resist these forces, the rectangular pressure vessel must be made of a substantial gauge of stainless steel, which is then reinforced with an equally impressive rib cage. The amount of energy required to bring all that steel up to 140°C and hold it there for any period of time, is colossal. To complicate matters further, to satisfy high throughput demands an additional steel box (so-called steam jacket) encases the rib cage. By keeping the steam jacket hot between cycles, operators can bring the pressure chamber up to sterilising temperature more quickly.

But putting a second cube around the first cube does nothing to address the challenge of keeping such an incredible mass at 140°C. Most manufacturers address this issue by wrapping the double-walled steam box with an insulating blanket. Adding insulation makes it easier to reach and maintain sterilisation temperature, but makes the double-walled steel box difficult to cool. To help reduce cooling time the solution is to flood the steam jacket with cold water at the end of each cycle. The result is a high-volume, high-throughput steam autoclave capable of running cycles back-to-back all day and all night with minimum downtime.

However, this design is a recipe for high energy consumption; even when idle, a rectangular chamber autoclave can constantly consume countless gallons of fresh water and kilowatt-hours of power. Although a autoclave built with a rectangular sterilising chamber has its place in a laboratory or research environment, it can be a financial disaster.

A cylindrical chamber autoclave can achieve virtually the same throughput and at much lower costs. Due to the natural shape of a cylindrical pressure vessel, it doesn’t require a reinforcing rib cage nor steam jacket, and has far less mass to heat and to cool. Cylindrical chambers easily manage intense pressure, and thus can be manufactured from lighter gauge steel; roughly one-third as thick (see figure 2).

The overall design weighs less and is the most economical to produce, which ultimately is reflected in the initial laboratory autoclave purchase price. Also, the design uses in-chamber steam generators (electrical elements like a kettle) that require fewer moving parts, waste little heat and will completely powered down when not in use, consuming zero energy.

Safety first

Whether cylindrical, square or rectangular, the chamber wall is under constant stress. Faulty workmanship will be exposed, perhaps, with lethal consequences.

Prior to final autoclave assembly these pressure vessels will undertake critical pressure tests far in excess of the standards laydown by European Pressure Vessel Directive -97/23/EC or the ASME Boiler and Pressure Vessel code, Part VIII, Division 1 accreditation for products being shipped to North America. Any device bearing the ASME stamp must have been independently verified to fully conform to the stringent design, construction and testing standards of the ASME Boiler and Pressure Vessel Code. Autoclaves are also built to international recognised standards and CE marked to:

- BS 2646-1993

- BS 5500 cat.3.

- EN61010-2-41.

- ANSI/UL 61010-1, 3rd Edition

- CAN/CSA-C22.2 No. 61010-1, 3rd Edition issued

- BS EN 61000-6-1

- HSE Note PM73

Purchase check list

Other notable design points to consider when purchasing an autoclave are:

- Temperature interlocks to protect against the hazards associated with liquid loads

- Pressure interlocks on rapid opening door systems

- Patented mechanical failsafe door retention devices guarding against residual pressure

- Regulation safety valves to BS EN 4126-1

- Reliable and long lasting door seals

- Low surface temperatures

- Non-tip shelves on front loading models

After the initial purchase, further investment in a service contract may seem an unnecessary expense. However, with proven extended life expectancy arising from regular servicing, inspection and validation checks, laboratory life continues without interruptions. There is a much lower ownership cost because regular servicing extends the payback on that original capital outlay over many more years. In the UK, competent autoclave service companies operate a UKAS calibration laboratory; temperature probes and test equipment carried by the engineers are regularly tested and verified for accuracy.

A simple task is the inspection of the chamber door seal both visually and by feel (see figure 3). It enables the engineer to identify any damage that could lead to escape of steam, potentially dangerous for lab staff as well as preventing satisfactory completion of the sterilisation process.

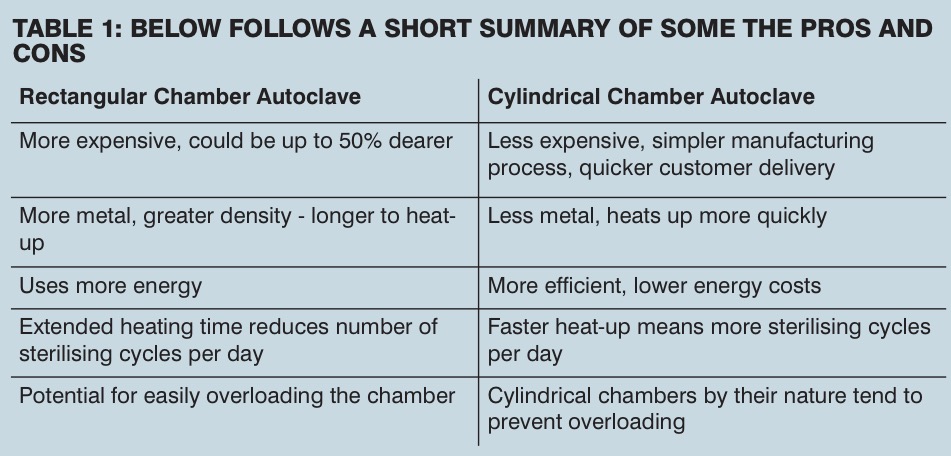

Size for size chamber capacity, it would seem that a rectangular chamber autoclave offers better loading for high throughput requirement than that of a cylindrical machine, but as explained, it might not be the right choice when it comes to factor operational costs (see table 1). In fact, a cylindrical chamber autoclave often offers a lower cost of ownership and is more energy efficient.

Autoclave manufacturers engineer their products to offer specific solutions to meet customer sterilising requirements and available laboratory space.

Typical sterilisation applications cover media preparation and laboratory waste sterilisation before disposal, but with the flexibility of cycle settings offered by laboratory grade autoclaves other loads such as glassware, instruments and porous loads can also be processed. All are critical in the maintenance of good hygiene practice and sterile working conditions.