Ford has announced it is investing $3.5 billion to build the country’s first automaker-backed LFP (Lithium iron phosphate) battery plant, offering customers a second battery technology within Ford’s EV lineup.

This plant – called BlueOval Battery Park Michigan – initially will employ 2,500 people when production of LFP batteries begins in 2026. Ford will have the option to further grow its battery capacity at its Marshall, Michigan, plant, which will be part of a wholly owned Ford subsidiary.

With this $3.5 billion investment, Ford and its battery tech collaborators have announced $17.6 billion in investments in electric vehicle and battery production in the US since 2019, as part of the company’s commitment to invest over $50 billion in electric vehicles globally through 2026. In the next three years, these investments will lead to more than 18,000 direct jobs in Michigan, Kentucky, Tennessee, Ohio and Missouri and more than 100,000 indirect jobs, according to the methodology from a 2020 independent study.

“We are committed to leading the electric vehicle revolution in America, and that means investing in the technology and jobs that will keep us on the cutting edge of this global transformation in our industry,” said Bill Ford, Ford executive chair. “I am also proud that we chose our home state of Michigan for this critical battery production hub.”

LFP battery chemistry

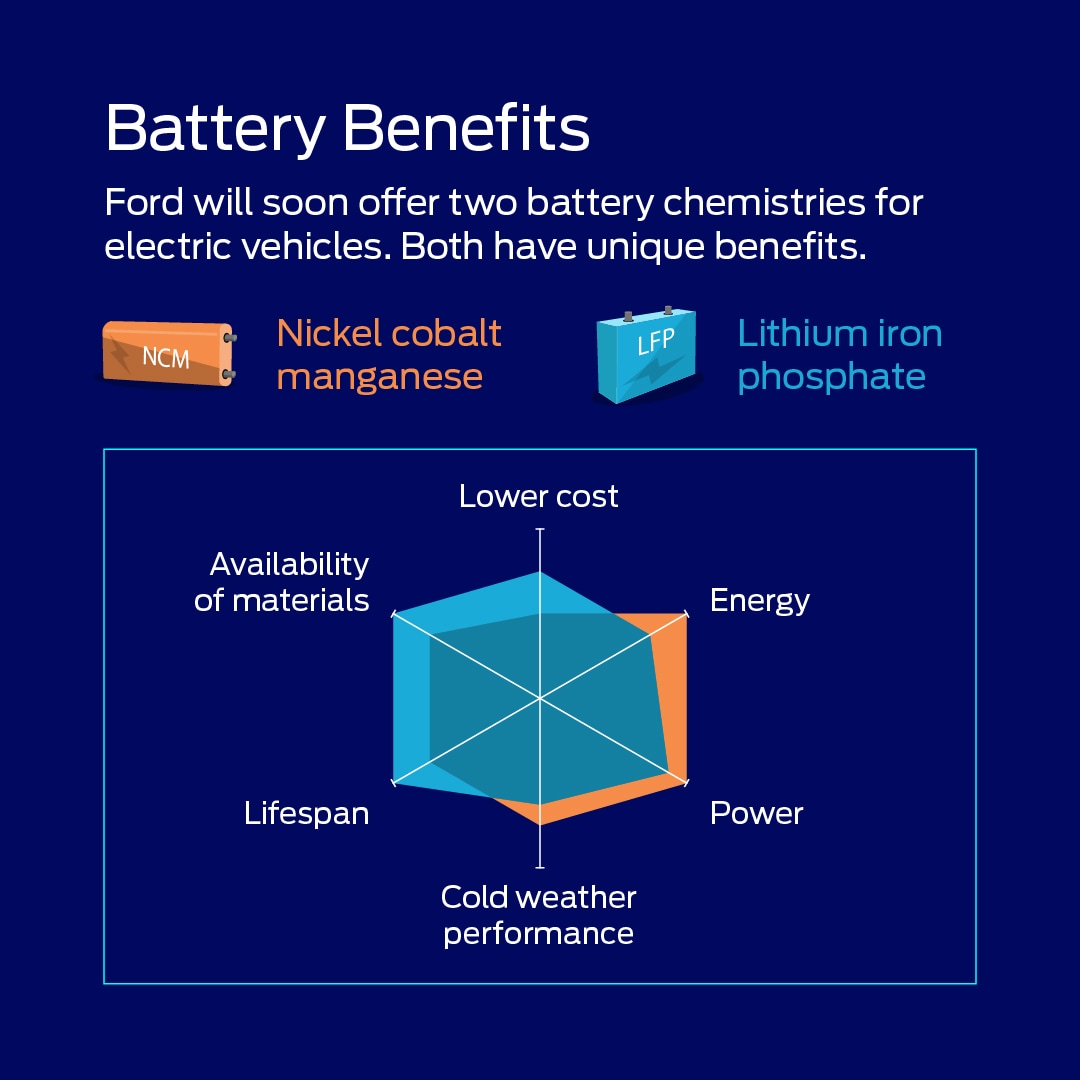

Offering LFP as a second battery chemistry – in addition to nickel cobalt manganese (NCM) – allows Ford customers to choose an electric vehicle with unique battery performance characteristics most aligned with their needs.

LFP batteries are very durable and tolerate more frequent and faster charging while using fewer high-demand, high-cost materials. This lower-cost battery, at scale, will help Ford contain or even further reduce EV prices for customers. These LFP batteries will power a variety of affordable, next-generation Ford EV passenger vehicles and trucks under development, most of which will be assembled in the US.

“Ford’s electric vehicle lineup has generated huge demand. To get as many Ford EVs to customers as possible, we’re the first automaker to commit to build both NCM and LFP batteries in the United States,” said Jim Farley, Ford president and CEO. “We’re delivering on our commitments as we scale LFP and NCM batteries and thousands, and soon millions, of customers will begin to reap the benefits of Ford EVs with cutting-edge, durable battery technologies that are growing more affordable over time.”

Even before the new battery plant opens, Ford will introduce LFP batteries on Mustang Mach-E this year and F-150 Lightning in 2024 to increase production capacity, with a goal of reducing wait times for customers.

Manufacturing facility in the US

This all-new battery production facility in Michigan will add approximately 35 gigawatt hours per year of new battery capacity for Ford in the U.S. initially – capable of powering approximately 400,000 future Ford EVs.

“Ford’s $3.5 billion investment creating 2,500 good-paying jobs in Marshall building electric vehicle batteries will build on Michigan’s economic momentum,” said Michigan Governor Gretchen Whitmer.

As part of Ford’s plan to offer a new battery chemistry and source in key regions where it produces EVs, Ford has reached a new agreement with Contemporary Amperex Technology Co., Limited (CATL) – the world’s leading battery manufacturer. Under the arrangement, Ford’s wholly-owned subsidiary would manufacture the battery cells using LFP battery cell knowledge and services provided by CATL, which has operated 13 plants in Europe and Asia.

Ford engineers will integrate these LFP battery cells into its vehicles. This new agreement with CATL adds to Ford’s existing battery capacity and available battery technology made possible through a series of key collaborations – including with SK On and LG Energy Solution (LGES).

Sustainable EV supply chain

LFP battery technology helps reduce reliance on critical minerals such as nickel and cobalt and is in line with Ford’s work to create an EV supply chain that upholds its commitments to sustainability and human rights.

Ford already has committed to achieving carbon neutrality globally across its vehicles, operations and supply chain by 2050. Ford was among the first American automakers to align with the international community to limit the impacts of global warming as part of the Paris Agreement and joined RouteZero, a global coalition working toward zero-emission cars and vans globally by 2040 and in leading markets like the US, Europe and China by 2035. Ford also was the first US automaker to release a human rights report.

Community support

The company is ensuring that 245 acres at the southern edge of the site are placed into a conservation easement. This land, along the Kalamazoo River, will be preserved for generations to come and protected against future industrial development. Ford will work with government officials and community leaders to preserve natural resources and recreation near the facility, as part of its commitment to being a good neighbour. The Ford Fund also will contribute resources to help the community explore how to best enjoy this beautiful land.

“The City of Marshall welcomes this exciting new partnership with Ford Motor Company,” said Marshall Mayor Jim Schwartz. “This investment in the local community will lead to an influx of new jobs to Marshall and economic development throughout the area. We are especially excited to support Ford’s conservation easement which will preserve Michigan’s natural beauty along the Kalamazoo River.”