Cleanrooms today are made up of various sized environments needing control and monitoring. From the ballroom style “clean” working areas to the bench-level workspaces, fan-powered clean spaces are required to meet the customer’s requirements. Often, to ease cost constraints, there is a growing placement of higher purity cleanroom minienvironments inside a larger ballroom space.

AC fan-powered systems continue to be the major building block in these situations, as cost barriers continue to reduce the appeal of higher efficiency DC brushless platforms. Additionally, innovations in AC fan-powered control systems have improved the cost, performance, and efficiency of the AC driven system. This is closing the gap between the lower cost AC driven FFUs and the more expensive but more efficient DC brushless driven solutions. This article reviews present systems, closed-loop control implementations, and the resulting improved cleanroom systems capabilities.

Existing solution systems laminar flow stations (example)

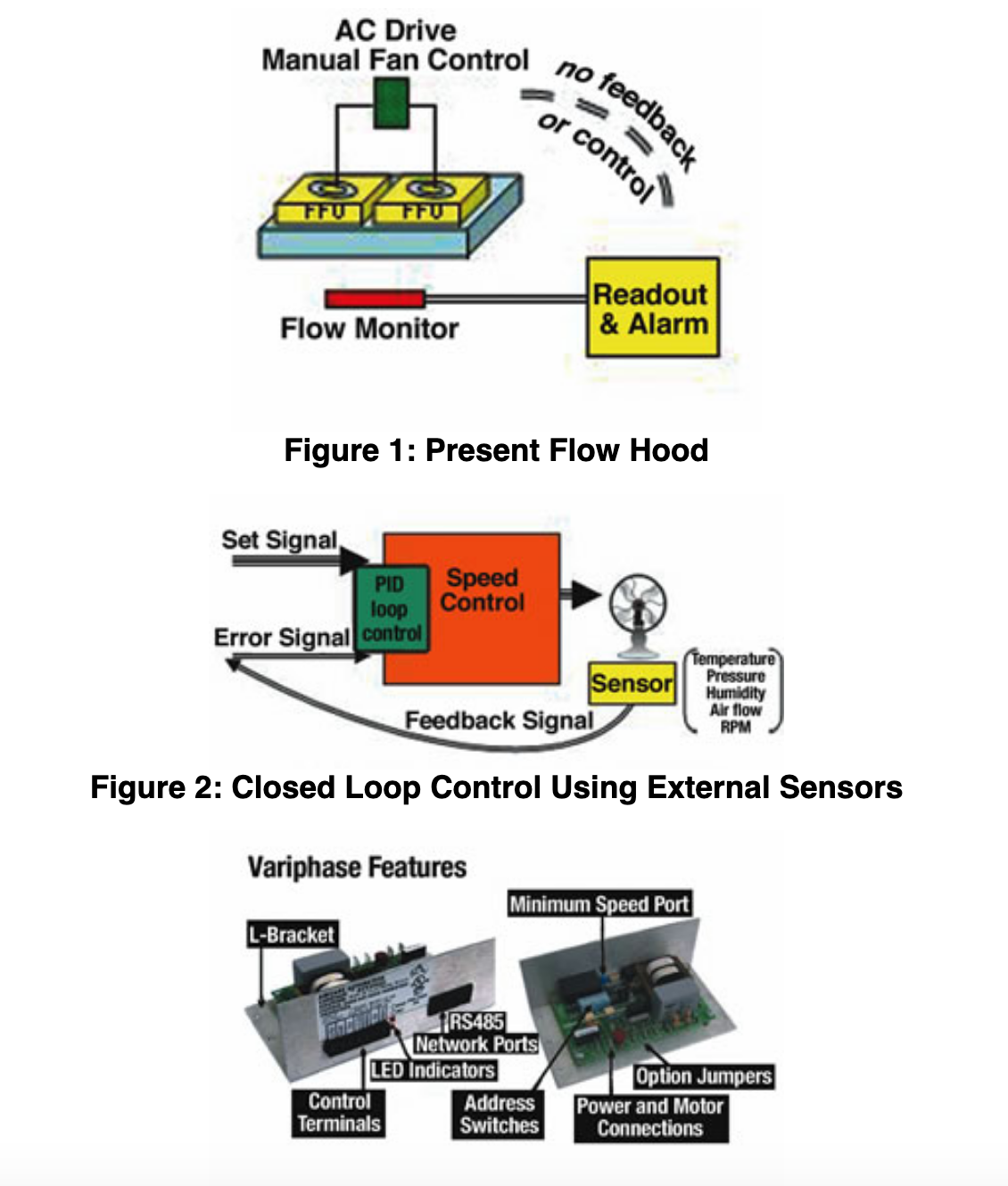

Most laminar flow stations today do not use closed-loop controls. A typical system is depicted in Figure 1.

The laminar flow hood has one or more filter panels with associated fans for proper air flow and control. The fan speed is set manually to meet the desired criteria (i.e. pressure, air flow). A separate sensor is used to measure the desired criteria providing a readout of the measured value. Setup is often comprised of manually adjusting the air-flow, waiting for the system to stabilise and monitoring the resulting readout until the proper setting is achieved. The flow meter may have an alarm to alert the user if the flow migrates beyond an acceptable range.

In order to optimise the performance of the flow hood and reduce user maintenance, a closed-loop control system would allow the user to set the desired operating point and allow the system to stabilise to the desired setting automatically. An added benefit would be if the alarm system were integrated into the system to allow for monitoring and notification when the system goes outside an acceptable range (system out of compliance).

Closed-loop control considerations

The key ingredients of a closed-loop control system can be summarised as follows:

1. A mechanism to provide linear changes in the fan speed to allow for control of the fan and maintain the measured and desired environmental levels.

2. Closed-loop feedback algorithms: logic necessary to provide stable convergence on the desired set-point and stability to maintain the set-point under step change environments. This is often achieved with an adjustable P.I.D. (proportional, integral, differential adjust) control algorithm.

3. A second feedback node: needed to compare the external measured signal to the desired set-point. This will allow for an “error signal” to be established and provide a mechanism to tell the fan to speed up or slow down.

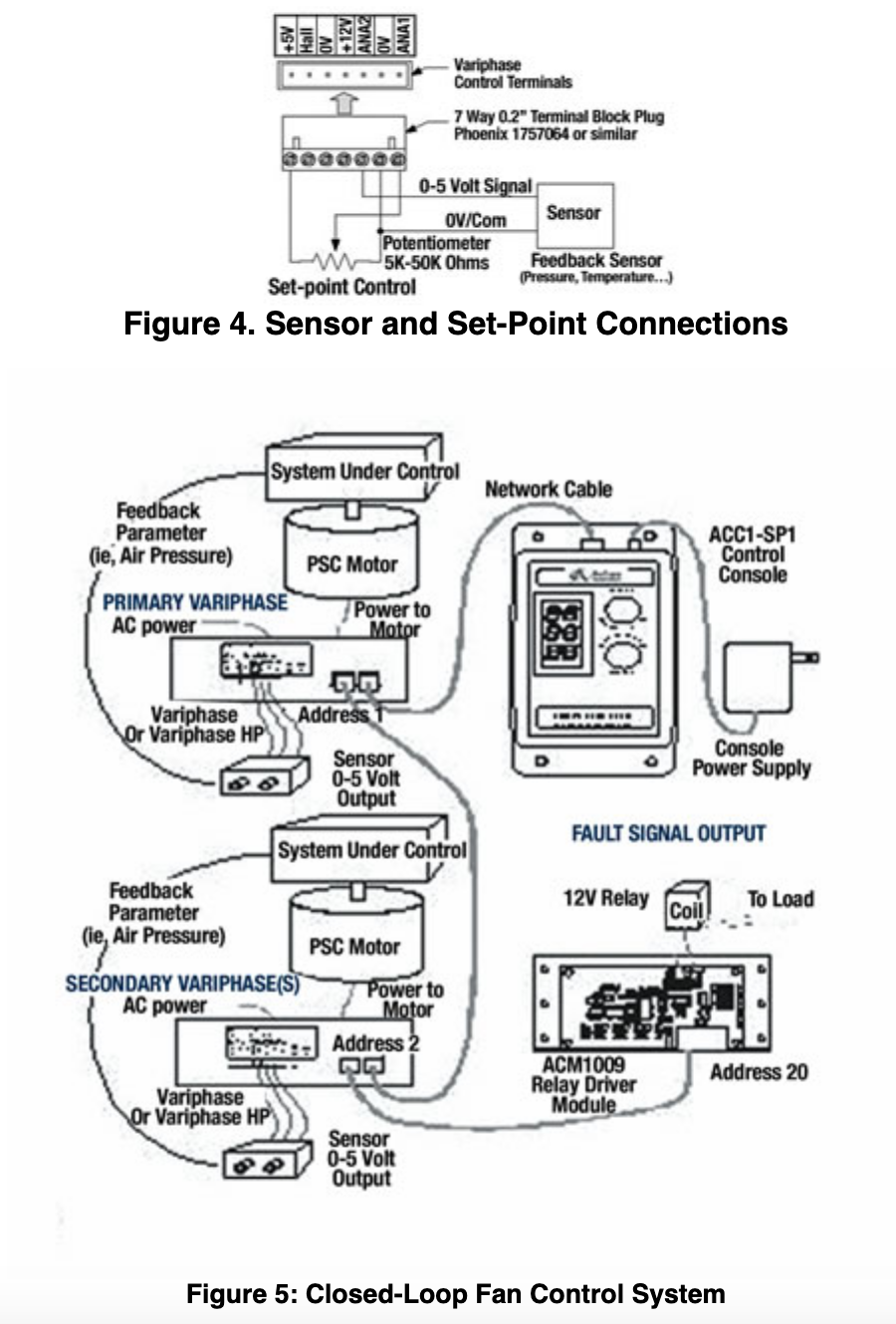

4. External sensors that can measure the desired parameter to be controlled and provide the feedback signal in the appropriate form needed by the controller (i.e. 0-5V, 4-20 mA, etc.). See Figure 2 for a simple block diagram of the desired system.

A closed-loop solution set

Using an existing platform composed of the AirCare VariPhase, we can modify and upgrade the product features and begin to address these additional speed control needs. The platform already has the linear speed control designed in along with a full PID control loop for RPM control. The VariPhase was then modified to incorporate a second Analog input (Analog 2). The limitation of the existing product architecture is that Analog 2 must be a 0-5 volt feedback signal.

Additionally most sensors require a power source that is often supplied independently. The platform was further modified to provide a 12 volt supply to bias power for the external sensor (eliminating cost of an extra power supply)

With software complementing this mode of operation, the inherent features already built into the platform (up to 1% accuracy, low cost, robust, fully functional PID control) could be tapped into.

The AirCare Console was modified to provide a monitoring and setup tool to allow for adjustments of all the key criteria, including the P, I, and D parameters. This allows for a digital readout and set-point tool as well as adjustments needed to stabilise any control environment.

Lastly, an additional component was created—the “Alarm-Relay Module” to allow for the console to not only monitor and display the set-point and measured values, but also to be programmed to trigger an alarm if the unit veers out of compliance. The key factors are minimum and maximum acceptable values along with a delay time before the system is determined to not be converging (often under step environmental change conditions, it may take from seconds to minutes to stabilise the environment; the alarm system allows the user to determine for themselves the appropriate delay time before raising an alarm to the user).

Thus, in its basic mode the AirCare VariPhase can interface with “any” sensor that provides a 0-5 volt feedback signal and will control the speed of the fan (in stable fashion) to manage to a set-point relative to the sensor. Fan speed and accuracy are driven by the sensor accuracy. Figure 5 shows the full system implementation with several closed-loop systems controlled by the same console.

The key features can be summarised for a self-contained system:

- Ability to control the fan speed—variable speed control

- Ability to stabilise the closed-loop to maintain stable air flow—PID loop control

- Ability to monitor and signal a fault condition—monitor/readout/fault-trip

- Ease-of-use: Simple to use and set up, uncomplicated command sets—out-of-the-box

- Cost effective-reduce system cost

Conclusion

Traditionally, closed-loop minienvironment controls have been expensive and cumbersome to implement. Fully integrated solutions have been cost-prohibitive and have been significant barriers-to-entry into the flow hood and minienvironment arena.

Extending the capabilities of the smart phase-control AC fan platform, a closed-loop control system can be implemented at a reasonable cost. The system described above provides not only the flexibility and sophistication to allow for environment-by-environment customisation but also provides cost-effective building blocks to allow environments built to meet the requirements without added expense and extra bells and whistles. These new tools and products will facilitate the use of closed-loop systems on next generation equipment.