As of the end of May 2022, more than 143 million COVID-19 doses had been administered in the UK since this unprecedented immunisation campaign began in 2020. Both here and worldwide, there is no doubt that the pandemic vaccination programme has done much to raise the profile of research into, and deployment of liquid pharmaceutical drugs.

The liquid pharmaceutical market has been growing due to the importance of biologics and cancer drugs that are produced more effectively in liquid form. Historically drugs were produced in solid form, which takes years of development to ensure shelf-life stable solid doses. As demand has pushed for faster-to-market drugs, manufacturers must keep pace with production methods to make that happen.

A robust quality assurance programme has strong product inspection capabilities at its centre

The market has changed, and the production of the COVID-19 vaccine has been a catalyst for change in producing more liquid pharmaceuticals directly into bottles, vials and ampules as standard packaging formats.

Manufacturers in liquid pharma understand that they will face the most serious consequences if they get things wrong. If, for example, they provide a product with an incorrect dosage size, it could be fatal for a patient. The other main issue is counterfeit medicines. The US has addressed this in the Drug Supply Chain and Security Act (DSCSA) in order to provide measures to minimise counterfeiting, and most other territories follow this lead.

With these issues in mind, liquid pharma manufacturers must operate at the forefront of product quality standards, ensuring that their dosages are correct and safe to protect consumers and patients. To comply with DSCSA, the packaging, labelling and in-pack product information must be accurate and up-to-date as well as be able to trace their products through manufacturing processes and the supply chain. Delivering transparency and proof of their legitimacy against counterfeits will help in securing safer pharmaceuticals.

Of course, these issues must be addressed while still operating efficiently, to get safe, cost-effective liquid pharma products to market quickly. There can be no compromise on quality standards, and this means that product inspection solutions must be deployed in both manufacturing and packaging processes in order to follow Current Good Manufacturing Practice (cGMP) guidelines set by the US Food and Drug Administration (FDA). For manufacturers, there are also some very specific needs to address. As discussed below, these steps support quality assurance in liquid pharma packs:

One: Fill level control

The nature of liquid pharma products is that they must contain an exact amount of dosage, usually held in small, fragile packs such as glass vials and bottles. There is a lot that can go wrong here: the dosage amount might be under- or over-filled; the bottles themselves may not be completely uniform, with slight, but very important, fluctuations in tare weight; the size and shapes of these vessels makes them inherently prone to toppling over and breaking during processing.

The use of a checkweigher that is capable of these levels of precision and product handling delivers further benefits to liquid pharma manufacturers

Both the unfilled and filled weight of each bottle or vial might be extremely light, and therefore weighing systems must be capable of very sensitive and accurate weighing. Checkweighers using high-performance Electro-Magnetic Force Restoration (EMFR) load cells can meet the precision and accuracy required. Careful handling of this kind of fragile primary packaging, including sorting and rejection mechanisms, is a must to reduce the risk of downtime caused by broken or damaged vials. All of this is required to happen at standard production speeds.

The use of a checkweigher that is capable of these levels of precision and product handling delivers further benefits to liquid pharma manufacturers. It provides weighing data that demonstrates the attainment of certified weighing standards required to support compliance with industry and government regulations. It also brings with it an economic argument, as well as a product quality argument. Accurate weighing that identifies over- and under-filling errors helps meet weights and measures compliance, reduces the costs involved in over-filling and product give-away, and lessens the potential for reputational damage – and the costs that extend from that – to the manufacturer.

Two: Completeness control

In liquid pharma, a product is only complete when its packaging includes instructions for use, most commonly in the form of a folded leaflet. The difference in weight between a pack with a leaflet and that of one without can be very subtle and weighing technology of great precision and sensitivity is required.

Checkweighers are able to detect these slight variations in weight and can do so without disrupting production speeds. They can also feature a countercheck function, which checks rejected products to ensure that they have been correctly identified as off-weight.

As with fill levels, while the primary benefit is ensuring the safety of users, having the product inspection capability to identify and correct these kinds of issues before a product is distributed can save manufacturers a great deal in terms of cost and reputation through avoiding product recalls. It also supports them in meeting compliance requirements, such as those set by FDA 21 CFR Part 11, which requires an audit trail of changes to be created and stored electronically.

Three: Serialisation

Serialisation is not just sensible, but is a requirement. With each product assigned its own unique serial code there is now full track and trace of individual packs, from origin to point of sale. If a problem arises and a product recall is deemed necessary, serialisation potentially enables more targeted recalling of affected products, rather than larger batches.

Serialisation also supports regulatory compliance, and in liquid pharma it can also play a specific role in combatting counterfeit medicines, giving assurance that a legitimate medication is being distributed.

Packs of medicines bearing a unique and verifiable serial code bear a hallmark of quality, in that they immediately suggest legitimacy and responsibility on behalf of the pharma manufacturer. This impression of quality can be enhanced or degraded by the quality of the coding itself. Whether it is presented on a pre-printed label or printed directly onto the package, the code needs to be clear and legible, with no smearing or skewing.

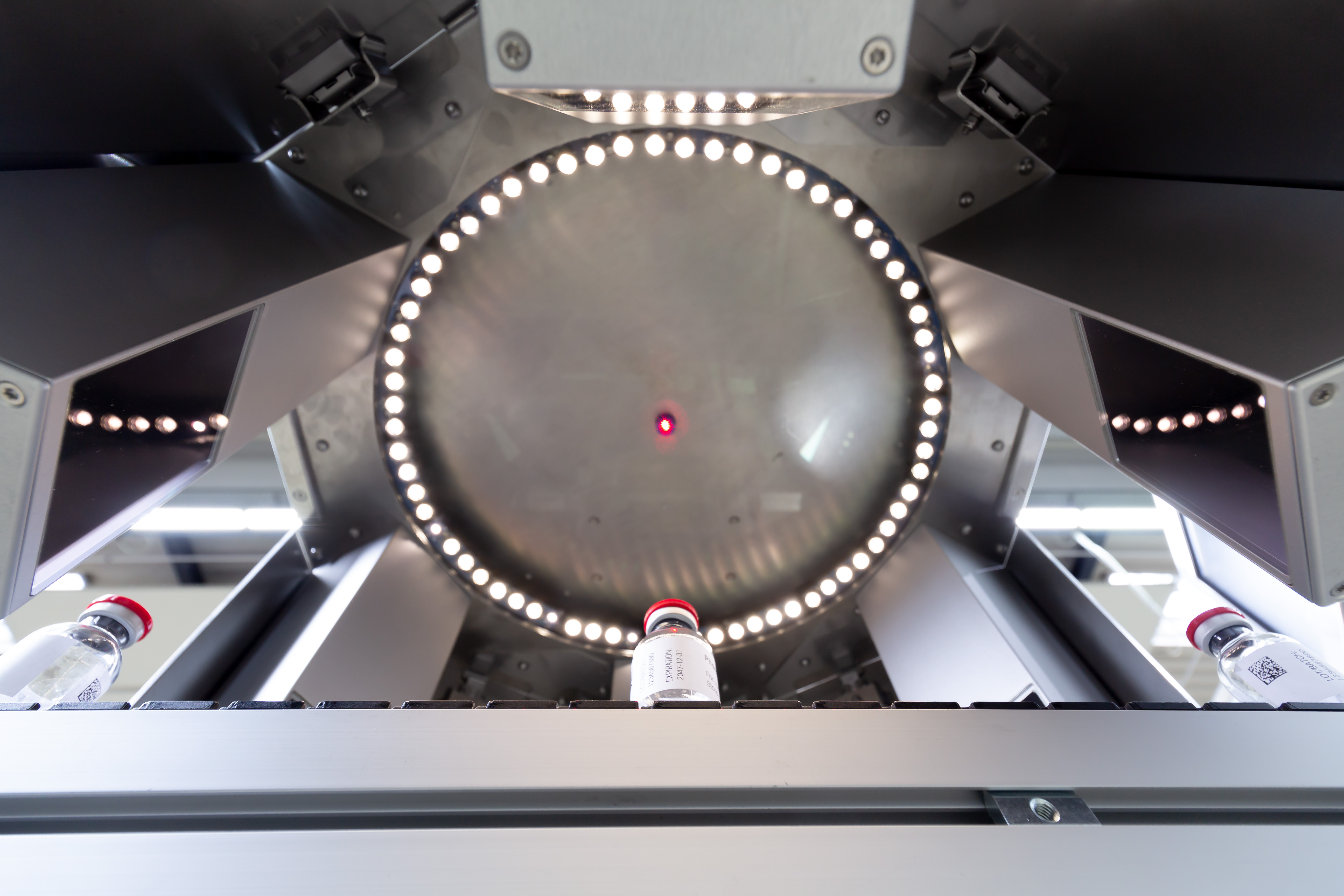

With vision inspection systems, these issues come sharply into focus. They can read serial codes and verify them, and identify those products with incorrect or poor-quality print. Liquid pharma products typically come in a variety of bottles or vials of differing shapes and sizes. Unfortunately, with these types of round containers, they may rotate on the conveyor line, and potentially obscure the visible printed codes. Serialisation equipment must be flexible in its ability to print and inspect these containers, and it may be desirable to choose a vision system that provides a complete 360 degree view of the product surface, so that the codes can be verified.

Four: Aggregation

Aggregating products into larger batches makes supply chain logistics run more efficiently, with easier tracking of products. Aggregation is growing as a mandatory requirement in many countries (legislation specifically in the US is coming into effect in 2023) and is therefore necessary for compliance. Along with serialisation, it also combines to help in the fight against counterfeit medicines.

There are some technical challenges involved in aggregation, in particular, where unoriented products such as bottles, or vials are packed into a case and the codes are therefore difficult to read. Printed helper codes on the tops or bottoms of bottles can help to mitigate this situation. However, it is a challenge requiring co-ordination as this increases the number of steps on the production line requiring additional equipment.

It is important for liquid pharma manufacturers to make sure that their aggregation systems offer support for a variety of round containers, can inspect top or helper codes, and can verify small detail datamatrix codes. Advanced camera technologies will offer either a fixed focal lens or liquid lens to accommodate inspection of various detailed datamatrix codes. In addition, because the serial and aggregation data need to be shared with the supply chain, it is critical that these systems can interface with Level 4 and Level 5 systems effectively.

Five: Software connectivity

It cannot be emphasised enough: software is crucial in accurate and effective serialisation and aggregation. The tracking of products, real-time process monitoring and inventory management cannot happen without it.

Software connectivity is a huge challenge, but addressing it is a must-have. By equipping product inspection systems with the right software connectivity, manufacturers can gain that real-time picture which will help to identify problems, and possibly prevent them from occurring in the first place.

Typically, liquid pharma manufacturers will have checkweighing (for fill-level and completeness checks), vision inspection and track and trace software within their product inspection regime. While these systems perform very different functions and record different data, they must provide robust user security and process monitoring, as well as the ability to connect and communicate with standard systems and processes already in place in the production line. With FDA CFR 21 Part 11 requirements in mind, they must also produce a local audit trail that records activity such as user logins and adjustments to machine set-up.

Conclusion

Quality in liquid pharma is a multi-faceted aspiration, incorporating the manufacture of the medication itself, and the processing and packaging stages that bring it into the supply chain. A robust quality assurance programme has strong product inspection capabilities at its centre. Product inspection technology such as checkweighing, vision inspection and track and trace are the manufacturer’s friend in helping to check that products are safe, complete, compliant, and traceable through the increasingly digitalised and connected supply chain.

That they must do so without compromising the manufacturer’s speed to market, and cost-efficiency performance makes the challenge of quality management still greater. However, with the application of good planning and the right technology, it is a challenge that liquid pharma manufacturers can meet.