SkyWater Technology has announced the US Department of Defense (DoD) is planning to invest up to US$170 million for a multi-phase project to enhance microelectronics capabilities for the DoD and the Strategic Radiation Hardened (Rad-Hard) market. SkyWater will be expanding its Trusted Foundry facility to add cleanroom area and supporting infrastructure to enable this and other complementary technologies.

The investment will see SkyWater expand its existing building footprint to accommodate supporting infrastructure and 8,000 sqft of new cleanroom area. The expanded cleanroom area will enable new rad-hard process technology as well as unique and dedicated processing for a select number of commercial customers for applications unrelated to rad-hard applications.

The initial phase of the project is funded at $80 million. SkyWater said it will leverage this investment to develop a new 90 nm rad-hard electronics production capability to complement its existing 90 nm rad-tolerant offering. In addition, it will fund SkyWater to add copper (Cu) dual-damascene interconnect technology to the facility. The move marks a significant advancement for the company's mixed-signal and interposer offerings.

Future phases of the effort include options for more advanced microelectronics capabilities.

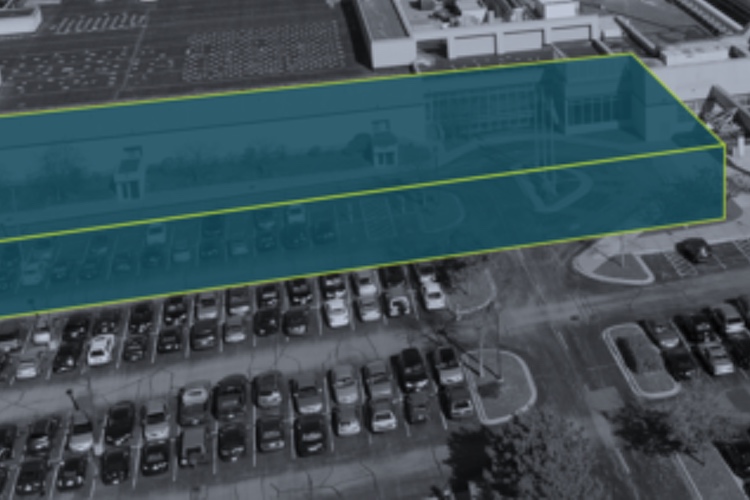

The planned expansion. Image as seen on company website

Focus on commercial markets

SkyWater's expanded rad-hard process will be based on PDSOI (partially depleted silicon on insulator) technology and will enhance the reliability of critical microelectronic devices in harsh conditions such as space and military field deployments. This enhancement to SkyWater's US production operation will extend new offerings for the company's aerospace and defence customers, ensuring manufacturing excellence and high efficiency for this unique chip category.

Additionally, with SkyWater's strong focus on commercial markets, this postures the company to address non-defence related opportunities for hardened electronics such as commercial space operations, medical imaging and other applications in extreme environments.

The new Cu interconnect option at SkyWater increases IC (integrated circuit) performance with lower resistance and higher speed and interconnect density by exploiting the intrinsic electrical conductivity advantages of copper as compared to aluminium. This benefits mixed-signal technologies through higher density logic circuits and reduced losses in analogue/RF circuits, ultimately improving system performance and efficiency. The new interconnect capability is critical to support the company's roadmap for more advanced node geometries beyond 90 nm.

"We are very pleased to expand our support of DoD objectives with this new Strategic Rad-Hard foundry offering while also extending commercialisation capabilities for related technologies," said Dr Brad Ferguson, SkyWater Chief Technology Officer and head of SkyWater's government relations efforts.

The initial phase of the project is funded at $80 million and SkyWater will leverage this investment to develop a new 90 nm rad-hard electronics production capability

Dr Ferguson added: "The addition of copper interconnect represents an important material processing capability that SkyWater needs to support node scaling to 65 nm and 45 nm and aligns with our customers' technology roadmaps. Also, by entering the copper interposer market, we can help narrow the existing gap in North America for advanced packaging solutions and increase the breadth of our technology offerings."

Commenting on the project, Thomas Sonderman, SkyWater President, said: "As a solely US owned and operated Technology Foundry, we are committed to supporting aerospace and defence customers. This investment marks a deepening of our relationship with this community, reinforces the credibility of our business model and expands our technology platforms allowing us to also increase the scope of our serviceable commercial markets."