Working at MRC Systems, a day could take you from sector to sector, from micro-electronics to BSL containment. Sam Hussain is the Global Sales Manager that is in charge of revenue generation from all these streams in their entirety. A tall order, but how did he get there?

An education and early experience in business management and a rare juxtaposition with a family history of cleanroom involvement, meant Hussain was ideally suited to the controlled environment industry. "My father and his family have been involved in cleanrooms, from an HVAC, panelling and equipment perspective, since the 80s," he explains. "Therefore growing up terms like 'particle count' and 'ISO class' were the norm around the house!"

Hussain is in charge of revenue generation in its entirety

This distinctive combination was shown to work well as after Hussain joined Dubai-based MRC in 2013, he quickly moved from focusing purely on new business sales activities to being responsible for the company's complete revenue generation. Hussain says that this includes marketing, new business, repeat business and ongoing project variations, though he emphasises that he also remains a point of support on critical projects.

After almost 8 years, Hussain has a solid technical knowledge base and knows that this bridge between the engineering side and the client is critical to new business."Clients need you to add value, make suggestions and help contribute to the development of solutions if you are to be successful. Simply sending quotes and chasing is not enough," he says.

Even with a solid foundation of expertise in the field, Hussain likes to think at heart he is a people person. This is emphasised when he explains that the turning point of his career was realising that he is learning as much from the client as they are from him. Showing a humble trait that's importance in forming lasting connections can't be overstated."I believe being able to develop strong relationships with clients while adding value to them from a technical perspective has helped a lot in my position," he says.

Geography is crucial

When the conversation turns to business decisions, Hussain gushes about some of his favourite projects, covering exciting projects like supporting the UAE's 'Mission to Mars', and some of global importance like COVID-19 vaccine facilities.

Speaking about MRC's work on the MBRSC Space Centre, located in the UAE, Hussain enthuses about widening MRC's range of expertise."This was a completely bespoke project, with a complex scope of work and a very critical time frame. It was outside of our typical pharmaceutical focus, therefore we had a lot of process knowledge to obtain in order to add the value we wanted to. This had huge local and international exposure and was critical in the recent"Mission to Mars", a huge milestone for the Middle East."

The focus on tailoring solutions to exact needs of different clients is one of the big influences Hussain has had on the business of MRC."I changed MRCs approach to business development; to become more focused on bespoke solutions and problem solving. All projects are different and we add value by accepting that," he explains.

Somewhat of a rare entity based in the Middle East, Hussain has some unique insights into how the cleanroom company operates in this region."Competition in this sector is hard to define," he explains."It depends on the approach of the client in regards to how they contract out for their project. Typically our main competition in the Middle East market comes from elsewhere in Asia, as other European cleanroom companies have struggled to break that market just yet. While in Europe we either compete against the other big cleanroom names or their local partners and distributors."

Being that the international aspect of MRC's business model is the foundation of its business, Hussain has so much more he could say on the topic but stresses:"Our manufacturing presence in both Europe and the Middle East allows us to move our products and people around the globe with ease and in a cost-effective fashion. This also allows us to be more dynamic in regards to global demand and market changes."

I am learning as much from our clients as they are from me

Hussain believes that MRC's international presence and experience combined with high-quality products is one of the keys to the company's success. This is demonstrated by the 20 countries a year (on average) that MRC completes projects in.

In the last year, Hussain says they have been of not one, but three COVID-19 vaccine facilities."[These] are complex and interesting projects, however, I am most interested in our upcoming projects within the cell and gene therapy sector. These are not huge facilities but they house very interesting state of the art processes. These projects are based in both Sweden for Takura and the UAE."

To what extent should you prefabricate?

It is the high regard Hussain has for bespoke solutions that makes him wary of the increasing norm of 'fast track' projects."Each project presents its own unique challenges; from differing scope of work, location, contractual setup, process and industry to regulation," he says."However 'fast track' projects are becoming the norm, which does limit the time clients can dedicate to detailed design work. I feel this trend could limit the client's access to the best bespoke solutions available to them."

To combat this, Hussain's advice is to bring a cleanroom contractor in at the earliest stage possible of facility planning. As a key contributor, from design to validation, he explains that they can add to the project from both a technical and a project management perspective.

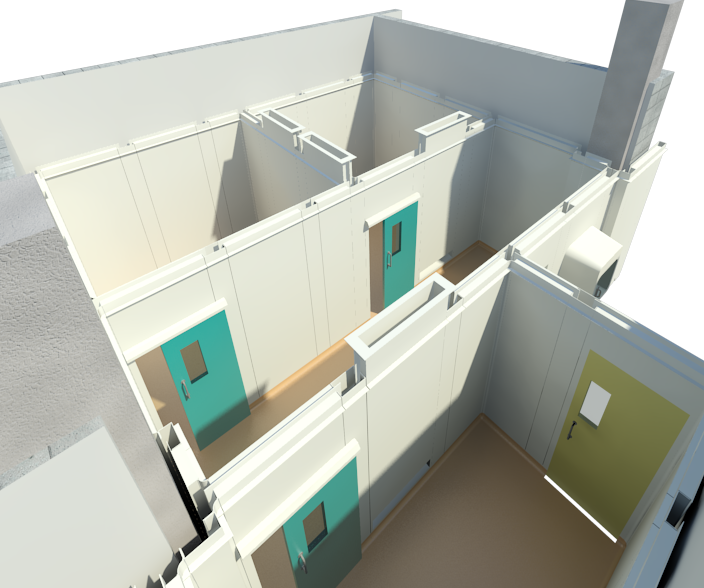

Once again, Hussain upfront nature is telling when he talks about modular solutions from MRC and the idea as a whole."I think the concept is intriguing to a lot of clients and we have recently undertaken some interesting projects," he explains."A few years ago many thought the industry would move more in this direction but personally I'm not sure I agree: I see similar prefab module-based solutions on the market, however, these systems are generally expensive, not as quick to deliver as many clients would initially believe and do have design limitations. In my opinion, civil construction and internal cleanroom fit outs, with a modular panelling system, remain the most cost-effective, high quality and flexible solution available."

When it comes to MRC's own modular offering, BOXlab, Hussain takes a balanced approach. He says that he would assess each project and propose the MRC BOXlab approach only where he knows it will add real value to the client.

This tempered excitement is mirrored in Hussain's discussions of flat sheets compared to moulded one as a construction philosophy. He explains that the debate surrounds flat sheet panels, typically standard sandwich panel, which is then converted to become a cleanroom system by adding coving details etc. and creating reinforced cut-outs to integrate furniture such as pass boxes. This compares to moulded construction, like MRC's GRP system, which starts with a liquid and a variety of flexible moulds. Meaning it can create the details and shapes required, in line with GMP and ISO design philosophies, in one single piece per panel. Hussain adds that no stick-on coving or corners, and products such as pass boxes and cupboards are manufactured as one with the wall panel.

Typically our main competition in the Middle East comes from elsewhere in Asia

The way Hussain sees it, the advantage is essentially to reduce the number of joints (therefore risk), while providing a facility that is easy to validate, clean, maintain/repair and modify."In our opinion moulded construction is therefore preferable, however, we also have the MRC HPL system which looks at combining the two approaches for certain facilities providing a more economical option."

A solid technical foundation and appreciation of the value of all people involved in the process are what make Hussain stand out in his field. In the last year, like many others, he has seen what used to be a behind-the-scenes niche market become almost mainstream."Knowledge and awareness of our industry seems to have grown within the general public, (describing my job seems to be a bit easier nowadays if I use the example of COVID-19 vaccine production!)."

Hussain explains that there are many sides to the effects of the pandemic on the cleanroom sector."From a business perspective; controlled environment demand remained strong during the pandemic, however, decision making and the speed of clients securing investment and financing did slow down," he says. However, this could be combatted by the increased awareness across new industries."I believe it will lead to a further growth in the requirement for controlled environments for new sectors."