The requirement for sterile processes and bioburden control in pharma facilities can incur high costs in terms of both filters and filter maintenance. Peter Koklitis, filtration specialist at 3M, looks at ways of improving filtration effectiveness to bring these costs down.

For today’s pharmaceutical businesses, continuous improvement of production processes is key to growing market share and maintaining profitability. The high standards for product safety and quality, which are set by regulators, place pressure on process economics. To achieve success in the marketplace, companies must strive to increase productivity while minimising batch failures, and must ensure the most efficient recovery from any such events. For processes requiring sterilising grade filtering or bioburden reduction, improving filtration performance while reducing the overall cost of filters can help meet these goals.

In processes requiring sterilising filtration performance, introducing a lower-cost pre-filter can be effective in preventing particulates from blocking the sterilising grade filter.

By offloading the responsibility for basic bioburden reduction from the main filter, the prefilter can also allow use of a smaller sterilising grade filter, thereby reducing overall filtration costs. It may be possible to save around one-third of the cost of filters in this way without compromising the integrity of the process.

In addition, if the introduction of the prefilter reduces blocking of the sterilising grade filter, the replacement interval can be extended, thereby reducing the costs of downtime, maintenance work and replacement filter units. However, a suitable pre-filter must be capable of sustaining high flow rates and low initial pressure drop if it is to maximise the improvement in economic performance of the process.

Bioburden reduction filters

Alternatively, in processes where sterilising grade filtration is not required, high quality bioburden reduction filters can help to reduce the overall cost of the filtration system needed to achieve a target flow rate.

Chemical or thermal compatibility issues can also restrict the choice of filter. For example, in bioburden applications requiring in situ steam sterilisation, or the use of aggressive sanitisation, or regeneration fluids, such as sodium hydroxide or acidic solutions, at concentrations of up to 1M (as used in column chromatography protection), high resistance to multiple cycles at elevated temperatures is needed. Some types of non-sterilising grade filters do not have the required compatibility and present a risk of issues, such as leeching of the filtration medium into the downstream column. Historically, this has sometimes forced designers to specify expensive sterilising grade filters for bioburden reduction.

There is also a case for using high quality non-sterilising grade filters in Large-Volume Parenterals (LVP) applications that handle many thousands of litres of liquids, such as amino acids, salt solutions or dextrose. Filters that offer high Log Reduction Values (LRVs) for micro-organisms such as B. diminuta or S. marcescens are effective in controlling bioburden and fine particulate for the extremely high volume of materials passing through the process. A high forward flow characteristic and low initial pressure drop can help reduce the number and size of filters needed to achieve the target flow rate for the process in these and other applications such as preparation of biological culture media.

Flow rate and process economics

The process flow rate is a critical parameter determining production volume, throughput and cost. Since inserting a filter for particulate and bioburden control introduces a finite resistance to flow, a system comprising several filtration elements may be used to achieve the required combination of filtration performance and flow rate.

As the filter medium captures particulates and organisms, resistance to flow increases, creating a differential pressure drop across the filter. Filter change-out is usually tied to a terminal value of this pressure drop. It follows that a filter displaying a low initial pressure drop, at the required flow rate, can help to extend the change-out interval. This has a beneficial effect on the productivity and cost of ownership of the process, by reducing both production stoppages and the costs of filter maintenance.

Moreover, filters offering a high flow rate and low initial pressure drop enable designers to meet process performance targets using fewer individual filters, thereby reducing the cost of the filter system.

Clearly an effective bioburden reduction filter must provide a suitable level of microbiological control, at the target flow rate. This demands high retention of micro-organisms, expressed in terms of Log Reduction Value (LRV) at a representative challenge concentration. For applications such as production of serum and blood fractions, low protein binding is also desirable.

Fundamentally, the ability of the filter to meet targets for microbiological control as well as flow rate, pressure drop and chemical compatibility depends on the characteristics of the filter medium. A variety of non-sterilising grade filters on the market today use fibre media such as a polypropylene and glass-fibre mix.

Membrane technologies using materials such as polyvinylidene fluoride (PVDF), nylon, all polypropylene, and polyethersulfone (PES) enable filter designers to adjust the pore dimensions and structure, and to control other material properties using techniques, such as coatings or charging, to optimise the filter’s performance for various applications. Pore sizes commonly offered for non-sterilising grade applications are in the region of 0.2µm to 0.45µm.

Polyethersulfone (PES) is an example of a filter medium that offers broad chemical compatibility and wide pH tolerance, allowing use with caustic or acidic fluids as well as high flow rates, low initial pressure drop and high microbiological retention; hence it is suitable for a wide variety of applications. The PES membrane filters also display low levels of extractables, which provides the assurance that the filter will not introduce particles to the process during normal operation or flushing.

In fact, PES membranes are used in some high-quality sterilising-grade filters, such as the LifeASSURE PDA Filter Series from 3M. The PES membrane used in these filters is manufactured with a high degree of structural asymmetry, featuring larger pores on the upstream surface that decrease to smaller pores towards the downstream surface. This asymmetry provides greater contaminant holding capacity than a symmetrical design by presenting a greater upstream zone to retain the contaminants, which can help to extend service life. In addition, the asymmetric structure reduces resistance to flow, resulting in a lower pressure drop at a given flow rate compared with other membrane types.

3M has used a similar membrane construction, featuring the asymmetrical pore structure, in its LifeASSURE PNA Filters for non-sterilising grade applications. The membrane has a single-layer construction, whereas the sterilising grade products feature a double layer, thereby providing the basis for cost-effective prefilters or bioburden control filters capable of outperforming other fibre and membrane-type filters typically used in numerous food, cosmetics, brewing, LVP and biotech processing applications.

Pleated polypropylene filters, such as 3M’s Betafine XL Filter Series, or all polypropylene depth filters. such as the company’s Betapure NT-P Filter Series, are also suitable for some pre-filter applications.

Performance optimization

Other aspects of the filter design must be considered, to maximise the flow rate and useful lifetime that can be achieved using an asymmetrical PES membrane. Pleating can be used, for example, as a means of increasing the useful surface area of the membrane while achieving compact overall filter dimensions.

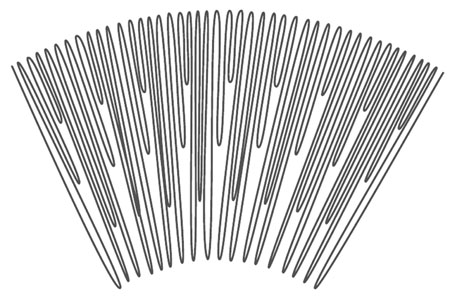

As a further development of this principle, the variable pleat depth featured in 3M’s asymmetrical PES membrane helps to maintain open flow paths and maximise filter life by ensuring even distribution of removed particulates over the membrane surface. Figure 2 shows how advanced pleat technology is applied to the PES membrane. This contrasts with the tendency for particles to accumulate predominantly around the upstream edges of uniform, full-depth pleats.

Figure 2: Advanced pleat technology maximises the useful surface area of the membrane

In addition, careful design of the membrane support structure, incorporating polypropylene distribution layers positioned both upstream and downstream of the membrane, helps to distribute the flow evenly across the entire membrane surface. This can provide an appreciable boost to the flow rate and pressure drop characteristics, without compromising the retention performance of the filter.

Combining all these techniques, including the membrane with asymmetrical pores, optimised pleating and upstream and downstream distribution layers, elevates the typical performance of non-sterilising grade filters. With a membrane pore size of 0.2µm in LifeASSURE PNA020 Filter Series, these technologies combine to achieve LRV greater than 7 with B. diminuta (ATCC 19146) when challenged at a concentration of 107 CFU/cm2 or greater.

The LifeASSURE PNA045 Filter Series membrane, which has pore size of 0.45µm, has been shown to provide an LRV in excess of 8 for S. marcescens (ATCC 14756) when challenged at a concentration of 106 CFU/cm2 or greater. This performance provides access to effective bioburden and particulate filtration at a competitive price, allowing performance targets to be met while also reducing cost of ownership by requiring a reduced number of smaller-sized, lower-cost filters.

Meeting targets

Table 1 presents flow rate and pressure drop characteristics for the LifeASSURE PNA020 Filter Series, and shows that targets for high flow rate and low pressure drop can be met using relatively few filters. In addition, since the same materials are used as in the sterilising-grade filters, these bioburden reduction filters can be introduced quickly and easily into almost any process. Regulatory support information is also provided with these types of filters, to help customers to validate new processes.

| Table 1. Flow characteristics for non sterilising-grade filters with a 0.20µm PES membrane | |||

| Filter | Typical water flow rate | Initial Clean Pressure Drop (water) for a 30-inch filter flowing at 76 l/min | Number of 30-inch filters needed to provide a 170 l/min flow with a clean pressure drop of 69 mbar |

| 3M LifeASSURE PNA020 Series | 17 l/min per 100 mbar | 152 mbar | 5 |

In conclusion, when used as pre-filters, non-sterilising PES filters incorporating advanced design features can provide effective protection against contamination for valuable downstream equipment, thereby helping to reduce process ownership costs. Designers can also specify smaller, lower-cost sterilising grade filters to be used in series with the pre-filter.

The combination of a low initial pressure drop and high maximum pressure drop capability also allows longer replacement intervals when used for pre-filtering or bioburden control, thereby saving maintenance costs and downtime. Compatibility with a wide variety of fluids, the use of construction techniques normally associated with sterilising grade filters, and the availability of regulatory support information simplify use in a variety of applications and market sectors throughout the pharmaceutical industry.

3M, LifeASSURE, Betafine and Betapure are trademarks of 3M Company.