The People’s Republic of China recently switched from US to EU GMP guidelines. A hypothetical facility was designed in an academic exercise by students* that provides an example of how the Chinese are looking to implement the guidelines.

Following the updated GMP guidance implemented by the Chinese State Food and Drug Administration (SFDA) in March 2011, the People’s Republic of China implemented a new version of its Good Manufacturing Practice (GMP) standard, now called China GMP 2010. The previous version, China GMP 1998, applied cleanliness grades set out by the US FDA. However, China GMP 2010 completely adopts the EU GMP cleanliness standards and the “in operation” classification was introduced.1 Therefore annex 1, on the manufacture of sterile medicinal products, led to a new challenge.

The aim of this project was to design a facility for the aseptic production of the powdered beta-lactam broad-spectrum antibiotic cefuroxime sodium that would:

- Mitigate any contamination risk

- Offer the most simple and effective workflow for material and staff

- Meet specific cleanroom classification standards

Project outline

Each vial of aseptic powder for injection would contain 0.75g of cefuroxime sodium (without excipients/additives) and would be packaged in the following manner: 7ml per vial, 10 vials per small box, 10 small boxes per large box and 10 large boxes per bin.

The facility was designed as a “new build” extension producing 50,000,000 vials of injectable aseptic powder of cefuroxime sodium per annum.

Process flow design

The flow of materials was designed to be as efficient and logical as possible. The active ingredient of cefuroxime sodium is first sent to the API temporary storeroom through a room for outer package removal, a room for decontamination and an airlock. After being sterilised, it is then weighed and moved into the filling room. Rubber stoppers and aluminium caps are transferred to a corresponding temporary storeroom through an outer package removal room, decontamination room and airlock. They would then respectively be carried into the filling and capping room after washing and sterilisation.

Meanwhile, vials would go through the washing machine, sterilisation tunnel and filling line and the sterile API would be filled into vials and the vials would then be stoppered and capped. Finally, the aseptic injectable powder would be inspected (using light), labelled and packaged. This process flow is shown in Figure 1.

The number one contamination risk is the filling station, thus care should be taken in the design of the piping and instrumentation, with the following design considerations.2

1. The level of automation and integration of equipment was very important for ensuring a sterile environment. This project used a filling line that covered aseptic core operations, including sterilising, filling, stoppering and capping, which is entirely fit for the “in operation” cleanliness grades given in the China GMP 2010.

2. The filling part of the screw filling machine was washed with water for injection and then sterilised, dried and re-assembled in a grade A environment. Sterilising and drying validation should be carried out after reassembly has been completed.

3. A high purity nitrogen protection technology, which can be decontaminated using a sterilised, micro-organism-retaining filter, is transferred to the filling room via a stainless steel pipe, and applied to protect the products being filled.

4. After sterilisation, rubber stoppers would be readily transferred to the stopper oscillator of the screw filling machine.

5. Using special storage tanks with sterile connection valves, the aseptic API would be poured into the powder hopper of the screw filling machine, so that the frequency, and therefore the risks to the aseptic operation, would be reduced. Sterile equipment should be connected in the grade A/B area.

6. In cases where allergenic dust of cefuroxime sodium could be generated, specific precaution would be taken to prevent cross-contamination, the generation and (dissemination) spreading of dust and to facilitate cleaning.

Facility layout

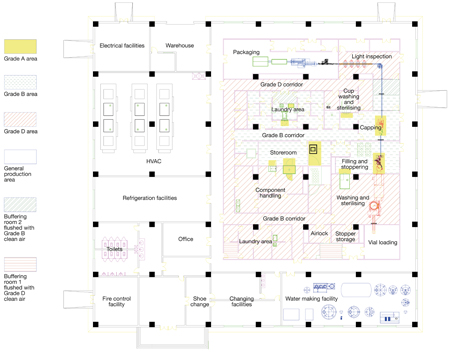

As shown in Figure 2, the facility comprised a total area of 2248m2 and the building dimensions were: 51m (length), 48m (width) and 6m (height).

The following building features were designed and selected to achieve the required cleanroom environment and to keep construction cost to a minimum:

- The Grade B area and Grade A/B area were located in the core zone in the inner circle and the grade D area was in located in the medium circle. Meanwhile, the general production area lay in the outer circle. The layout met the requirement for a “homocentric circle” design, which made monitoring and inspections more expedient and reduced the HVAC load because of the convergence in the layout of rooms of the same grade.

- Washing machine, sterilisation tunnel filling line and capping machine were installed in a line from south to north, which was beneficial to equipment maintenance and core zone environment control. Visual inspection using light and secondary packaging were also in a line from east to west. The packaging area was located opposite the receiving and dispatch bays of the warehouse.

- The core zone should be kept small and compact, thus the Grade B area only included filling, stoppering, capping and their auxiliary room. Double-ended sterilisers sealed into the walls between the grade D and B areas allow the components from the grade B area (rubber stoppers and aluminium caps) to be washed in the grade D area and then be deposited in the grade B storeroom after sterilisation, meeting the requirements of China GMP 2010 – namely that after sterilisation, the transfer and deposit of sealed containers, such as those used for packaging materials and components coming into direct contact with the aseptically prepared drugs should be carried out in a grade B environment and terminally washed, reassembled, packaged and sterilised in a grade D environment.

- Grade A vertical laminar flow hoods incorporate speed control fan filter units located within the modular ceiling grid system. In addition, filling and stoppering is carried out under nitrogen laminar flow.

- Four transfer windows were provided. Discarded waste should be transferred to separate discard storeroom via transfer window number 1. Components to be washed in the grade B area were sent to the grade D area by transfer window 2. Grade B area clothing could easily be put in the grade B area clothing laundry through transfer windows 3 and 4.

- Clean areas for personnel, equipment or for materials were provided with airlocks through which they could enter into production clean areas.

- To avoid contamination of clean area clothing or carry-through of contaminants into the core zone, the facility has a triple clothing changing system. Separate laundry facilities for clean area clothing are available.

- Provision of adequate working and in-process storage space permitted the orderly and logical positioning of equipment and materials so as to avoid cross-contamination and to minimise the risk of omission or the wrong application of any of the manufacturing or control steps.

- l In the grade B corridor, grade D corridor, filling and stoppering room, capping room, light inspection room etc, emergency doors were provided to ensure rapid personnel evacuation in the event of unexpected incidents.

Figure 2: Overview of facility layout

In conclusion, the biggest difference between China GMP 2010 and the previous 1998 GMP was that the previous version only emphasised the “at rest” classification, and the China GMP 2010 has also strengthened the quality management.

An experienced cleanroom designer should oversee every stage to ensure the successful construction of a cleanroom to the user’s satisfaction.3 It should result in a robust, ergonomic facility design, taking into account cleaning regimes, URS, production technology, the need to modify process equipment, API features and exposure risks.4 Only in this way can we really implement the core idea of China GMP 2010.

Reliance should not be placed on any one terminal process or finished product test for sterility, or other quality aspects, but rather on precise control of the entire manufacturing process and quality management.5

References

1. Yu Y., Lu C.Y. A Discussion on China GMP 2010 and Equipments of Injectable Aseptic Powder. Mechanical and Electrical Information of China. 2011, 29(5):20–24.

2. An B.Z., Ming Y.J., Liu Y.B., et al. The Requirement of Facility Design and Equipment for Injectable Aseptic Powder. Qilu Pharmaceutical Affairs of China. 2009, 28(6):375–377.

3. Liu M., Liu Z.C. Understanding of GMP Used in Process Design of Sterile Separation Packed Powder Injection Workshop. Pharmaceutical & Engineering Design of China. 2006, 27(3):33–36.

4. Pitcher M. Designing Isolators with Reliability. Cleanroom Technol. 2012, 20(3):19–22.

5. Zheng J.W. Automatic Infeed/Outfeed System Used in the Production of Freeze-dried Powder for Injection. Mechanical and Electrical Information of China. 2011, 29(35):30–34.

*Authors

Zhang Xiulan, Zhang Heng, Yang Yihong and Wang Kai, Key Laboratory for Green Chemical Process of Ministry of Education, Wuhan Institute of Technology, Wuhan P.R. China, 430073

Wang Jia, Wuhan Pharmaceutical Industry Design Institute, SINOPHARM, Wuhan P. R. China, 430077