As the life sciences industry responds to the COVID-19 pandemic in record fashion, cleanroom technologies have proven vital to efforts to combat the COVID-19 pandemic. In 2020, cleanroom provider AES Clean Technology introduced new offerings under their existing Faciliflex banner, delivering complete custom cleanrooms from scratch in as little as four months from concept initiation.

As many companies participated in the US Department of Health and Human Services- launched Operation Warp Speed (OWS), which provided financial and distribution incentives to develop new COVID-19 therapies, they also built new cleanroom facilities to meet the increased manufacturing demand.

In fact, if you receive one of the two COVID-19 vaccines currently approved in the US, there is a good chance that the vaccine or some of its ingredients were made in an AES Faciliflex cleanroom.

"The idea has always been to accelerate 'speed to patient,' a concept whose time we thought had come, which also turned out to be frighteningly prescient," said Josh Russell, Vice President of Sales & Marketing at AES Clean Technology. "Cleanroom development is fraught with complexities, so we created the Faciliflex program to take the risk out of our clients' cleanroom investments."

The AES Faciliflex product line includes the flagship Faciliflex custom modular designs; standardised, pre-engineered Faciliflex Express units; and "configurable" Faciliflex Module systems that allow clients to mix-and-match standard cleanroom processing suites for common unit operations. The flexsuite modular design leverages the benefits of processes that maximise the application of single-use technologies. With all of its Faciliflex products, AES Clean Technology offers an industry-leading guarantee to ensure performance of the temperature, humidity, pressurisation, cleanliness, containment, and commissioning requirements for the cleanroom.

In the age of COVID-19

Although it started as a mechanical systems designer, AES pioneered modular cleanroom design nearly three decades ago as the company began integrating wall and ceiling systems into its manufacturing portfolio. As their modular offerings became more advanced, the Faciliflex line became a way of meeting the needs of an expanding range of clients - from supplying modular components to soup-to-nuts mechanical and architectural design, manufacturing, and installation services.

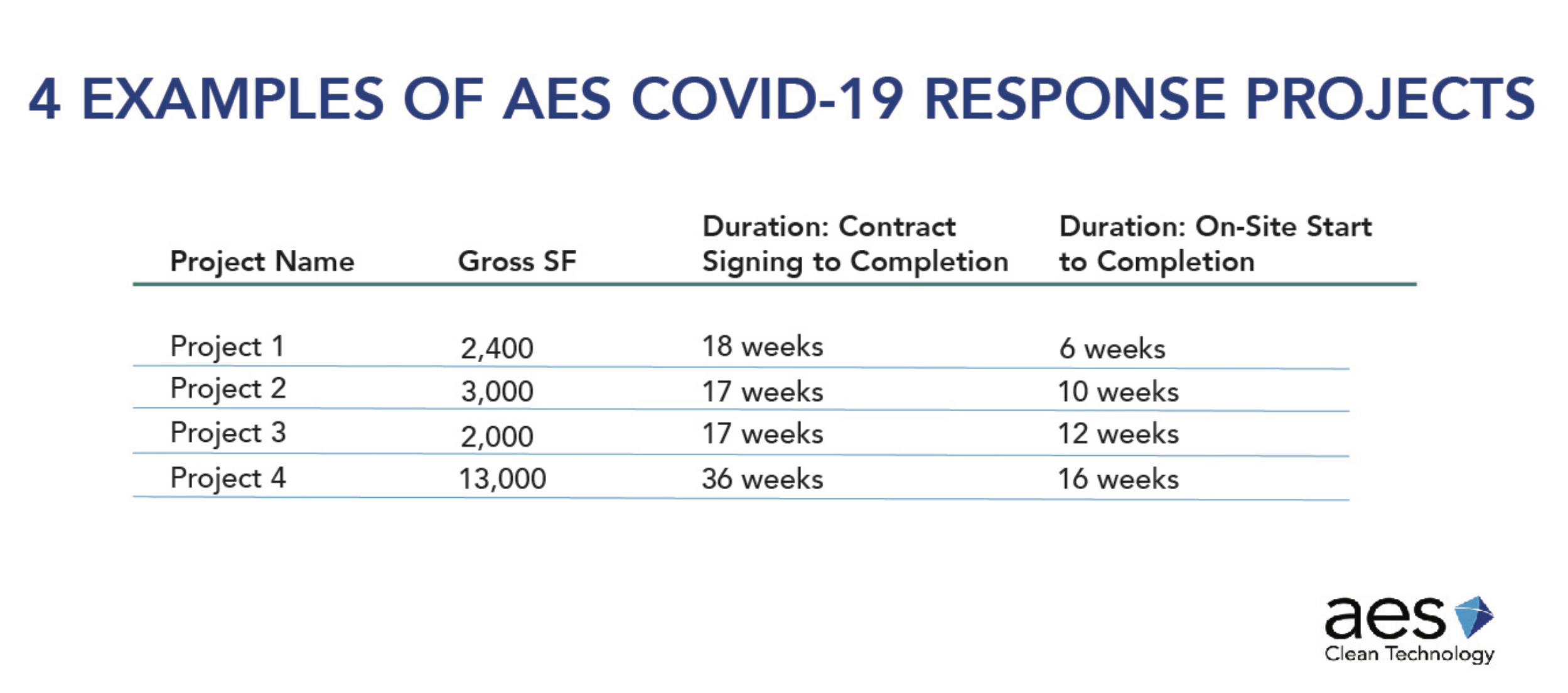

According to AES, the Faciliflex project approach helps clients by removing cleanroom design and installation as a risk to overall project timelines. It was a philosophy quickly put to the test in 2020 with three separate Operation Warp Speed clients, eight COVID-19 design build projects, and over a dozen additional COVID-19 installations with wall and ceiling systems. Four of their fast-tracked cleanroom builds, ranging from 2,000 to 13,000 square feet, were completed in record-breaking times.

"Typically, the industry commonly uses a design-bid-build approach to a cleanroom construction project," said Trista Hager, a project development engineer at AES. "Since time was a limiting factor, however, we worked with our clients to approach the project on a design-build basis, leveraging target value design and integrated project delivery."

Once the AES team established a set of parameters and the costs associated with their client's needs, they developed a project plan that coordinated engineering, design, manufacturing and construction in one integrated project team.

"In essence, we brought all the players together in one room – well, virtually, to maintain social distancing," Hager said. "In any cleanroom development, communications between the teams involved is paramount. In times of a global pandemic, it becomes absolutely critical, allowing for quick decision-making and coordination between the client, our production teams and, ultimately, the installation team."

The pandemic brought an array of challenges, especially in construction. For one thing, AES could often only have a certain number of workers on site at any given time to comply with best practices in social distancing. Additionally, because local expert installers were unavailable at the client's relatively remote and rural sites, they were required to send in a team and house them near the facility, which itself is a difficult prospect during a pandemic.

Despite the extraneous challenges associated with providing a cleanroom within an uncertain and changing COVID-19 environment, AES was successful in delivering this project and several other Operation Warp Speed projects on or ahead of schedule. This swift execution approach was critical in support of many critical vaccines getting to patients to curb the current pandemic.

Modular solutions reducing risk

Over the last 35 years, AES Clean Technology has learned that modular builds inherently incur less risk than conventional cleanroom projects and offer better coordination throughout design and integration. A previously approved modular build becomes, in essence, a known quantity, which simplifies the commissioning process.

"We constantly feed experience and expertise from every new build back into the design process so that each iteration takes advantage of lessons learned," Russell said. "Our clients are in the business of innovating new therapies, not construction, so leveraging our past experiences and standard designs accelerates the design-build process and provides the confidence with the end users that the facility will provide the operation and regulatory compliance required".

It was with speed in mind that AES launched Faciliflex Express in early 2020. Faciliflex Express took the lessons learned from years of modular construction to create a streamlined process to get a reliable product for quick delivery – important for both established life sciences firms and startups looking to move quickly to market.

Faciliflex Express provides three standardised, pre-designed cleanrooms in 5,000, 10,000 and 30,000 square foot units that can be built, packaged, delivered and permanently installed on nearly any site in as little as six months.

Configurable building blocks

In December 2020, AES introduced what their engineers and designers term the next logical development of cleanroom design: Faciliflex Module offers individual plug-and-play cleanroom processing suites that connect to a standardised baseblock.

The idea is to allow for nearly endless opportunities for customisation while maintaining the proven, risk-reducing benefits of standardisation. Faciliflex Module was created to offer a blend between their bespoke Faciliflex cleanroom designs and the prix fixe Faciliflex Express offering for a configurable modular cleanroom.

The Faciliflex approach removes design and installation as a risk to project timeline

"With AES Faciliflex Module, the daunting task of designing the best cleanroom facility for your needs becomes as simple as mix-and-matching the individual processing suites – we do the rest," said Mitch Gonzales, the AES Vice President of Process Technology. "Our designs offer a way for clients to build a cleanroom space precisely configured to their exact needs."

The Faciliflex Module concept begins with the controlled HVAC environment, which is the heart and soul of any cleanroom. From this baseblock,

clients can add any number of pre-configured attachments – from manufacturing to overlooked necessities such as storage, hallways or janitorial spaces – in any arrangement.

Like any building block, Faciliflex Module parts fit together. Wall panels and ceiling systems tie together like linking plastic bricks, but so do wiring and plumbing within the walls, customised to meet your specific requirements for gas or liquid delivery from suite to suite. Individual modules can be further customised to meet a variety of biological manufacturing applications, including:

- Gene therapy

- Cell therapy

- Allogeneic

- Autologous

- Viral Vectors

- Peptides

- Oligonucleotides

- Manufacturing filler and related substances

- Monoclonal Antibodies

- ADC/Potent Compounds

- Fill/Finish (Drug Product)

- Drug Substance

- Antibody-drug conjugates / Potent Compounds

Designing cleanrooms with Faciliflex Module becomes a matter of selecting pre-configured processing suites to meet a particular manufacturing need or overall workflow. According to the company, it also offers a way in which to make the best use of an existing piece of real estate.

Of course, it is not like flat pack furniture. clients are not expected to design and install a new cleanroom facility on their own. The Faciliflex product line is backed by the expertise of an AES design team that works with clients to factor in their exact cleanroom needs over a given space allowance.

The AES modular design allows for rapid manufacturing, shipping and installation, where each Faciliflex Module is fitted on site and easily connected to utilities. According to Pat Traver, director of Process Technology at AES, patient impact remains the driving force behind the continuing innovation of the AES modular system.

"If anything, the pandemic has reinforced just how critical speed to patient truly is for our clients in the life sciences and pharma industries – lives are in the balance," said Traver. "When time is the most critical factor, Faciliflex Express and Faciliflex Modules take the risk out of your project timeline with designed solutions backed by decades of innovation."