The US-based market research company said sales of consumables are steadily rising, while hardware revenues follow the same peaks and troughs as semiconductor, flat panel and medical device equipment sales. The pharmaceutical industry is the one major user of hardware steadily to increase purchases, the report has revealed.

Gloves are the single biggest consumable purchase, with wipes in second place.

Reusable and disposable garments are equal in revenue, but not in unit sales since more disposable garments are purchased.

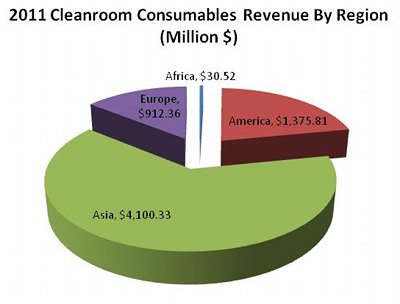

Asia is both the largest and fastest growing region for both consumables and hardware. Nearly all the flat panel display cleanrooms are in Asia. China is the fastest growing semiconductor producer and the US has managed to stay ahead of Europe thanks to its early innovations, which created much of the electronics industry.

The one area where Europe is a leader is in pharmaceuticals, with the industry purchasing cleanroom consumables totalling US$220m. This is greater than Asia, but less than the Americas.

Consumables revenue by region

Europe is also a leading centre of technology development, with many universities devoting research to the subject. There are also more than 50 conferences and exhibitions in Europe each year.

McIlvaine believes that future product selection and market shares for specific suppliers will be substantially influenced by ‘knowledge-based’ sales.

‘Cleanroom consumable purchasers tend to buy the lowest first cost product rather than the one with the lowest life cycle cost. If the knowledge level of the needs and the solutions is raised for both purchaser and supplier, then the best rather than the cheapest product will be used,’ the report has found.

McIlvaine has raised the knowledge level in the worldwide air pollution control industry and will now initiate that effort in the cleanroom market, starting with garment decisions in Europe. It will work with European cleanroom operators, laundries, distributors, garment manufacturers, validators and consultants and post information to a free website. It has also enlisted the help of Dr Hans Schicht, who has particular expertise in European pharmaceutical cleanrooms, and C W Berndt, an expert in garments and processing and a past president of IEST.

One early achievement has been to clarify the methodology for determining the environmental impact of single use and discussions are underway to look at cleanroom classifications in a more sophisticated way. Typically the hardware configuration has been used to determine whether a cleanroom is classified as Class 100 or Class 1000 (number of particles in a cubic foot of air). But European research shows that people are the particle generators.

McIlvaine says new concepts such as motion intensity, along with the numbers of workers/100m2, and outer and under garments are needed to evaluate the likely cleanliness of a specific room.

The company also aims to provide the structure and definition of cleanroom terms in many languages and is initially working with the Chinese and American Filtration Societies.