Clearly, art plays an important role in the food and beverage industry; creativity and imagination are essential in packaging and advertising, as well as in product development. Vaisala, however, believes that science plays the dominant role: developing measurement technologies; helping with product formulation; optimising processes; protecting safety; ensuring quality; enabling product consistency; and empowering sustainability. Looking forward, how will science help the industry overcome its latest challenges?

The challenges

According to the FAO(1), nearly one in three people in the world (2.37 billion) did not have access to adequate food in 2020. The worst affected countries were in Africa and Asia – and at a time when the main food-related challenges in some countries were obesity and food waste. Food security, nutrition and accessibility all present growing challenges.

Water scarcity can be defined as insufficient fresh water to meet normal requirements. It can be caused by climate change (drought), water contamination, excessive or inefficient water use, or by insufficient or failing water infrastructure. According to the United Nations(2), without adaptive measures, the number of people who lack sufficient water for at least one month per year will soar from 3.6 billion today to more than 5 billion by 2050. Again, there is a growing pressure for better efficiency and less waste.

Climate change is threatening crops which can be wiped out by drought, floods, hurricanes etc. According to the UN Office for Disaster Risk Reduction(3), climate-related disasters have almost doubled compared to the previous 20 years. Greater resilience is therefore required in our agricultural systems.

A limited shelf-life for many products imposes extra risk for the food and beverage industry, and makes it more vulnerable to supply chain problems. Therefore, there is a strong demand for measures to improve resilience and protect business continuity. Coupled with cost and sustainability issues, supply chains need to be short, fast, safe, and traceable. As well as sustainable products, consumers are also looking for better packaging, with less reliance on plastics.

Consumer demand for safe, healthy, nutritious food continues to grow. Manufacturers are therefore under growing pressure to provide better information on labelling; especially for ingredients with health considerations such as sugar, salt, and calorific content. Consumers are also increasingly looking for products with a low carbon footprint, and this is driving the growth in meat alternatives, for example. Carbon footprint information is being requested by retailers; frequently this now includes Scope 3 emissions, which are those that arise outside of their own operations.

With global energy and food prices soaring, food and beverage manufacturers are experiencing both environmental and financial pressures to improve energy efficiency, reduce waste and increase the use of renewable energy – wind, solar and biogas.

Science at Vaisala

Science is offering solutions to all the challenges outlined above, and Vaisala is actively involved in many of them. For example, Vaisala is the world’s leading manufacturer of meteorological equipment; enabling scientists to track climate change and extreme weather. In addition, Vaisala’s industrial measurement instruments enable better management of food and beverage processes, which:

- improves efficiency

- enhances and protects product consistency and quality

- reduces energy consumption

- reduces waste

- lowers costs

- improves the sustainability of the industry and helps in the fight against climate change

Vaisala technologies are employed extensively in the food and beverage industry, and many examples are given below, but in comparison with Vaisala’s global reputation in the meteorological business, the company is less well known – and may be one of the food and beverage industry’s best kept secrets, but most powerful assets.

The Vaisala brand is dictated by the company’s mission to provide observations for a better world through innovation that is driven by four key values:

- Customer focus – providing measurement solutions to meet customers’ needs

- Pioneering innovation – curiosity driving continuous improvement

- Collaboration – with partners, stakeholders and the global scientific community

- Integrity – honesty, diversity, respect, reliability and sustainability

In the food and beverage industry, Vaisala products are utilized at every stage of the value chain; from agriculture, to processing, to storage, to distribution, to retail, and to waste management.

Vaisala technologies

With accuracy and long-term reliability as pre-requisites in all Vaisala development programs, the company’s products have established an enviable worldwide reputation, and now boast installations on more than one planet! Humidity and pressure sensors from Vaisala are currently operating in every continent on Earth, as well as on Mars in NASA’s Curiosity and Perseverance rovers.

Humidity

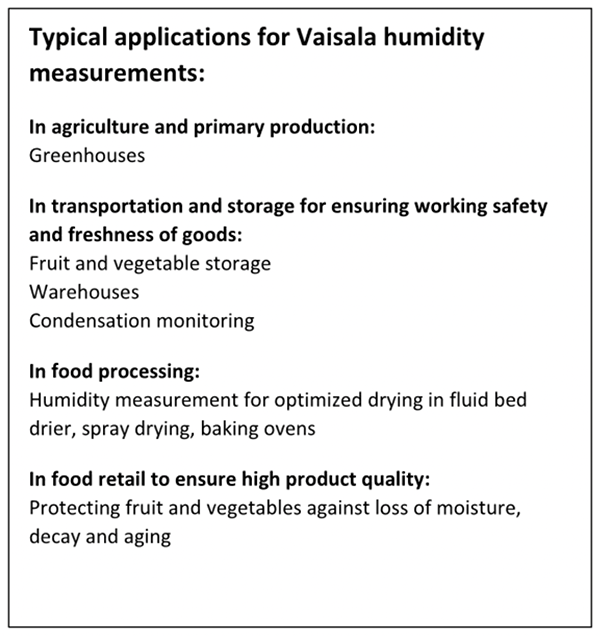

Some of Vaisala's core technologies include measurement methods that are commonly regarded as industry standards. For example, humidity is one of the most common measurements undertaken in almost every industry. In 1973 Vaisala developed the world’s first thin-film polymer-based capacitive humidity sensor, HUMICAP®, which dramatically improved the accuracy and reliability of measurements, with major advantages including long-term stability and insensitivity to condensation, dirt and most chemicals. As a consequence, Vaisala humidity probes are routinely employed in food processes such as drying, cooking, baking etc. The applications

for humidity measurements are almost endless; partly because excessive moisture in food can cause spoilage.

Carbon Dioxide (CO2)

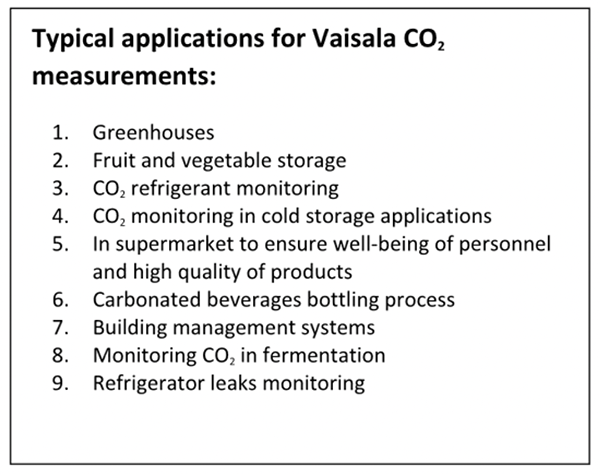

Carbon dioxide is used by plants to grow by photosynthesis, so it is common practice for horticulturists to raise greenhouse CO2 levels to boost production. CO2 is also used in carbonated beverages and in the manufacturing facilities of perishable foods, and all of these processes require tight control, so they are ideal applications for Vaisala’s sensor technology.

The Vaisala CARBOCAP® carbon dioxide sensor features an innovative micro-machined, electrically tunable Fabry-Perot Interferometer (FPI) filter which enables a reference measurement that compensates for any potential changes in light source intensity,

as well as for contamination or dirt accumulation in the optical path. Consequently, the CARBOCAP® sensor is highly stable over time, which means that operators do not have to worry about calibration drift or sensor failure.

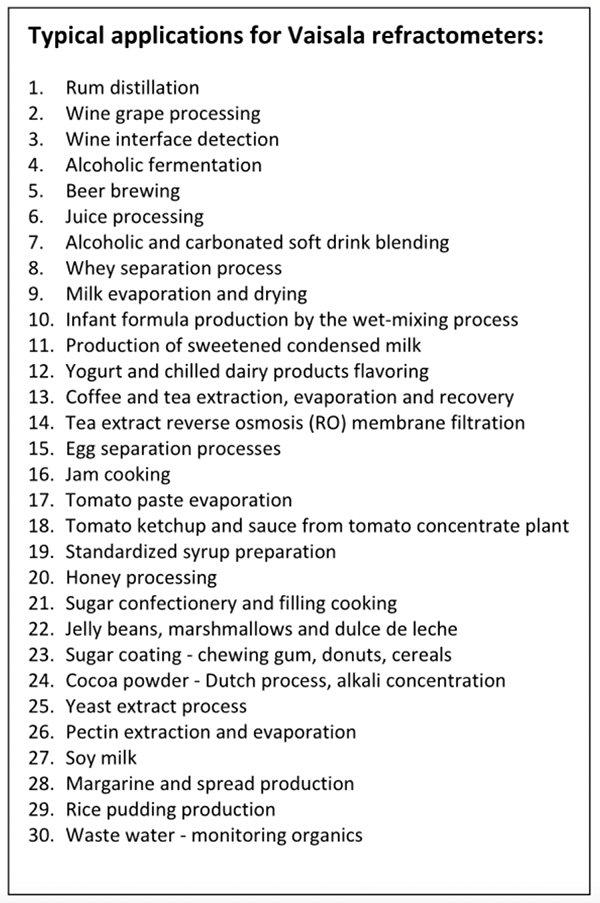

Refractometry is a well-known method for measuring sugar content in products such as beverages and fruit products, but the in-line Vaisala K-PATENTS ® Sanitary Refractometers are routinely utilised in countless food and beverage applications for process monitoring and control. For example, Brix and dry solids measurement are widely used in food and beverage production processes.

In contrast with many other liquid concentration methods, the Vaisala refractometer is not affected by particles, bubbles, crystals or colour, so these instruments can be employed in a wide variety of solutions for liquid identification and for monitoring the concentration of components. Importantly, the Vaisala refractometer is EHEDG and 3-A certified - these sanitary Standards protect hygiene in the production and processing of food.

Application examples for Vaisala in-line refractometers are given in the table opposite, but their versatility is demonstrated clearly by their involvement in every stage of the beer brewing process:

- Mashing - measuring the concentration of the mash in water at the outlet pipe.

- Lautering - measuring concentration to detect the appropriate shut-off point for rinsing.

- Wort Boiling - continuous measurements of wort strength/gravity allowing the brewer to determine exactly when the wort has reached the required strength.

- Whirlpooling – monitoring before and/or after the whirlpool to ensure that solids are removedquickly and effectively to produce a clear, bitter wort.

- Cooling - ensuring that the bitter wort contains the correct level of dissolved solids beforefermentation.

- Fermentation - providing brewers with real-time insights into the process, and allowing them toaccurately determine when fermentation is complete.

- Filtration and maturation – quality control during the removal of yeast.

- Filling and CIP - continuous monitoring of the filling and CIP processes enables automation, reduces wastage and lowers costs and energy use.

Biogas

Globally, there is an enormous focus on renewable energy and greenhouse gas emissions reduction, as countries and organisations seek to achieve Net Zero. Biogas offers an opportunity to utilise waste products from agriculture and food production, and also displace fossil fuels as an energy source. In addition, biogas processes produce digestate, which is a nutrient-rich fertiliser that can complete the circular economy in food production. In addition, biogas can generate electricity for use domestically and on farms.

Vaisala has developed technology to enable biogas process optimization. Uniquely, Vaisala’s multigas measurement instruments are able to monitor biogas inline and in real-time, which allows operators to improve the quality of biogas, lower costs and improve process efficiency. This final example demonstrates how Vaisala is involved in every stage of the food cycle, from food production all the way through to the anaerobic digestion of food waste.

Summary

Science can be defined as the pursuit and application of knowledge and understanding, following a systematic methodology based on evidence. At Vaisala, food is all about the science; measurement data from our instruments inform decisions and enable efficiency optimisation. Science at Vaisala is driven by curiosity; with 14% of net sales invested in research and development, the company has a longstanding commitment to innovation. The food and beverage Industry has benefited enormously from the technologies that Vaisala has already developed, but for the company’s scientists, the greater source of excitement is the technology that has yet to be unveiled…

References:

1. The State of Food Security & Nutrition in the World 2021. Food & Agriculture Organization of the United Nations: https://www.fao.org/state-of-food-security-nutrition/en

2. UN: Adaptation to Climate Change www.un.org/en/climatechange/science/key-findings#physical-science

3. United Nations Office for Disaster Risk Reduction, Policy brief: Disaster risk reduction and climate change. www.undrr.org/publication/policy-brief-disaster-risk-reduction-and-climate-change

4. Riddell et al. (October, 2020) The effect of temperature on persistence of SARS-CoV-2 on common surfaces. Virology Journal.

https://virologyj.biomedcentral.com/articles/10.1186/s12985-020-01418-7

5. Meat plants—a new front line in the covid-19 pandemic. (July 2020) British Medical Journal. https://www.bmj.com/content/bmj/370/bmj.m2716.full.pdf