For preventing cross-contamination coming from adjacent areas, several guidelines refer to a positive room-pressure of about 5- 20 (10-15) Pascals (Pa) as an essential factor for airflow from higher cleanliness to a lower cleanliness graded area under static conditions. To manufacturers of pharmaceutical products and the authorities controlling them, this cascaded pressure regime and room pressurisation (see figure 1) is seen as an essential element in preventing contamination (migration of particles) from adjacent outside areas.

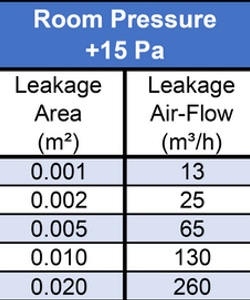

Table 1: Leakage airflow and leakage size

The physical fact is that room pressure depends only on the leakage-airflow volume and size of the leakage area in the room enclosure (see Table 1).

Airflow direction inside the cleanroom and supply-air and exhaust-air volume do not affect room pressure. To date, it is a misconception among QA departments and authorities that this room pressure can provide airflow to the less clean area through open doors.

The physics says absolutely no.

The door opening causes a temporary pressure impulse followed by a pressure balance of the adjacent rooms. If the door remains open the resulting airflow velocity only depends on the supply- and exhaust-air balance of these adjacent rooms.

Pressurisation and particle migration?