The quality and purity of steam has been fundamental to the healthcare and pharmaceutical industries for many years, yet food and drink products are often manufactured, treated, or processed with little or no analysis of the type of steam used.

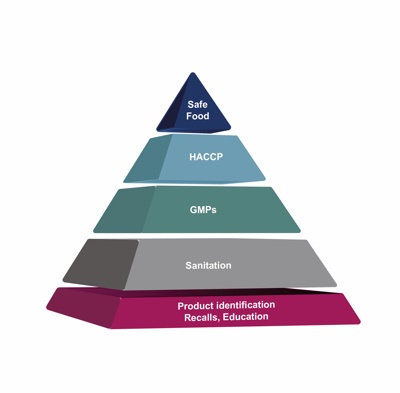

So why is the quality of steam so important? Since 1998, all food businesses in the EU have been legally bound to ensure the quality of their final product is maintained at all times and to have measures in place to identify and control potential hazards, based on the principles of Hazard Analysis and Critical Control Point (HACCP).

As a substance often injected into food, steam is one of these potential hazards. We all know that steam is sterile, but not quite as many realise that contamination both upstream and downstream of the pipework runs the risk of affecting the product, and ultimately, proving a hazard to human consumption.

The confusion surrounding the difference between filtered and clean steam could be proving very costly to many businesses — which is exactly why clear guidance is needed.

By understanding the pitfalls of not having a clean steam process in place, what a clean steam process should look like and the advantages it can deliver, a food and beverage company can make sure clean steam sits at the very top of any list of ingredients.

If something is filtered — as tends to be the case with the culinary steam we know within the food and beverage industry — does it automatically follow that it is clean? The answer to this question is a resounding no. The steam often used for direct injection is passed through a filter which only removes 95% of particles larger than two microns. This potentially leaves 5% of particles larger than 2 microns, which can significantly affect the final product. Ultimately, the business could be at risk of any of the following:

- Inconsistency in the taste and colour of their product

- Possible contamination

- Lack of uniform criteria for analysis methods

- Closure

Helping with HACCP

The key to food manufacturers eliminating these risks is a more widespread use of clean steam. Whereas some operators in the food and drink industries still view the use of clean steam as discretionary because of the lack of concrete regulatory requirements, it can be crucial in helping manufacturers to demonstrate that they are applying an effective food safety regime according to HACCP principles. The framework is increasingly a requirement from major retailers globally who legally, along with manufacturers, are responsible for ensuring the safety and quality of the products they sell.

In contrast to both plant and filtered grades, clean steam is already being used as standard in a range of quality-critical processes in other industries such as pharmaceuticals and healthcare, theoretically making it a go-to option for food and beverage manufacturers and processors.

What does a clean steam process look like?

Generating and using clean steam within a process means controlling feedwater quality at the source. By doing so, there is no longer a reliance on filtered steam, and this ultimately eliminates the risk of the final product being contaminated by the steam used in the manufacturing process. Since filtered steam can often be in direct contact with food, it must be dry and free of boiler water treatment chemicals.

Rather than relying on a filtration process to extract particulates, the production of clean steam utilises a secondary steam generator with the ability to control chemical-free feedwater quality.

The design of the steam distribution network, material selection and installation practices are all critical for minimising steam degradation, thus ensuring acceptable purity and quality at the point of use. As a result, clean steam requires the use of stainless steel pipework and components that eliminate the potential for corrosion of steam traps, valves, and pipeline equipment made from traditional carbon steel materials.

With the introduction of appropriate controls, companies need to decide whether the risk in relation to direct steam is acceptable or whether they need to mitigate against it. The absence of more appropriate control at the plant leaves the final product at risk of unexpected boiler-related contaminants. If a company determines that this is not acceptable, dedicated clean steam generation becomes more than just the desirable option – it becomes the only option.

Thankfully, technology is available which can control feedwater quality at source and help businesses which manufacture or process to eliminate the risk of contamination. In turn, this will help to keep the food and beverage sector firmly aligned with the HACCP process, and ensure the delivery of products with consistency, safety and quality at their forefront. Not only will this minimise wastages, it will also seek to improve productivity and more importantly protect the reputation of the brand.