Purdue University researchers have developed a new device that uses cold plasma technology, which could transform how medical tools are sterilised.

The device generates cold plasma through pure direct current high-voltage instead of the conventional radio frequency or pulsed DC power. This cold plasma has high potential to be used in the fields of sterilisation and disinfection, researchers said.

“We use high-voltage DC technology to create bursts of plasma to sterilise medical tools or devices,” said Alexey Shashurin, an assistant professor in Purdue’s School of Aeronautics and Astronautics, who developed the device along with his graduate student, Xingxing Wang.

“This interesting and unique approach is much safer and more cost-effective than radio frequency voltage or pulsed DC power methods to generate cold plasmas.”

The RF voltage or pulsed DC power methods cause electromagnetic interference (EMI), which leads to problems with some medical monitors and devices, and puts patients at risk. Conversely, the DC voltage cold plasma device simplifies creation of electrically safe system.

“Our cold plasma technology offers a much simpler and cost-effective system compared to e-beams or gamma radiation sterilisation systems,” Wang said.

“We are also using room temperature sterilisation instead of the traditional high-temperature approach, which requires more equipment and setup. Some medical tools, such as those involving plastic pieces, cannot go through high-temperature sterilisation processes. Also, DC cold plasma technology provides a more economic approach by using air as a sterilisation agent instead of chemicals.”

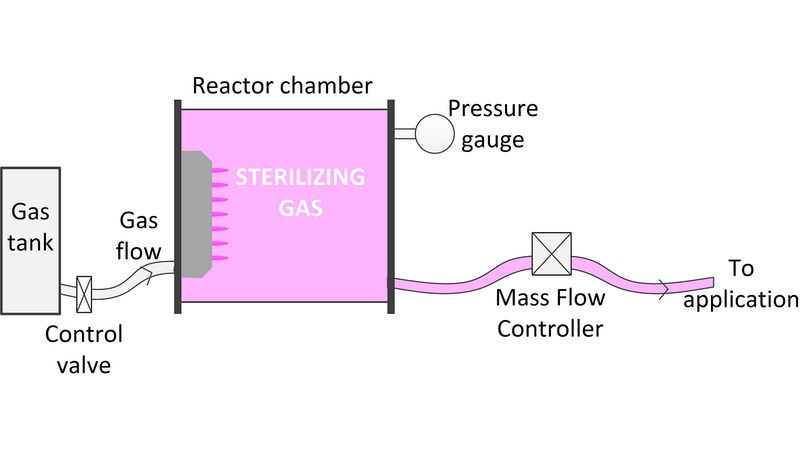

Device uses DC voltage cold plasma technology to produce a sterilising gas for medical device packaging

In addition to creating a cold plasma reactor, the researchers have developed a method to use the DC voltage cold plasma technology to produce a sterilising gas. The gas could then be used in creating less expensive sterile packaging for medical devices, a $21 billion industry in 2016.

“This device is a disruptive technology and may cause a paradigm shift in the field of sterilisation,” Shashurin said.

“The combination of being chemical-free, low temperature, simple and safe makes this a game changer in the medical tool sterilisation community.”

The Purdue team is also looking at other potential applications for the technology, including the germination power of plants in the agricultural industry; preventing bacteria in the food packaging industry; and cleaning surfaces in the manufacturing industry.

The invention won an award from Innovation Corps (I-Corps), a programme funded by the National Science Foundation and was chosen as a finalist for the Purdue Research Foundation-managed Trask Innovation Fund, a development mechanism to assist faculty with work to further commercial potential of technologies disclosed to the Office of Technology Commercialization (OTC).

A patent application has been filed by OTC and is available for licensing.

This article has been republished by Cleanroom Technology following permission by Purdue University. The original article can be viewed online.