There are many reasons why it is impossible to give a cleanroom cost as a price per square foot straight off — the main one being there are many variables to take into consideration. The objective in giving a price is to provide a fair costing for your project without endless extras. To do so, requires some preliminary engineering. A construction company would need to evaluate the design and make some calculations (mechanical and electrical). Engineers also might like to challenge the design, clarify any misconceptions and eliminate unnecessary spending. In other words, the company does not have a catalogue with prices for different types of cleanrooms; costing requires some preliminary engineering and computing before a price can be given.

If a supplier were to give you a quick price per square foot, you would be advised to run! Costs related to that cleanroom would be likely to snowball. The price quoted would be like a basic car cost, with roll down windows, no air conditioning and no radio. You do not want that in a cleanroom, so beware!

That being said, here are some aspects that influence the price per square foot of a cleanroom.

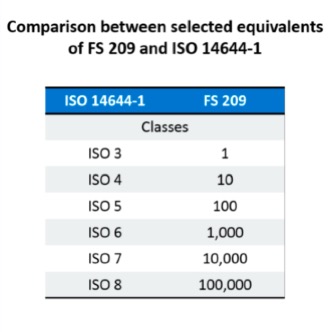

Cleanroom classification

An ISO 6 and an ISO 8 cleanroom are not the same price per square foot. A non-hazardous sterile compounding cleanroom or a hazardous sterile compounding cleanroom in negative pressure are not the same price for various reasons.

Firstly, the amount of air is different in an ISO 6 to that in an ISO 8. Remember the air is 100 times cleaner in an ISO 6 than in an ISO 8 cleanroom. Hence, the HVAC system must be capable of conditioning more than double the air. A cleanroom is not simply walls and ceilings; the heart of the cleanroom is the air treatment system (HVAC), which can represent between a quarter to a half of the price of the cleanroom.

In addition to the HVAC system, the cleanroom classification will also influence the required amount of enclosed rooms. For example, entry into an ISO 8 cleanroom can be directly from an uncontrolled environment. On the other hand, entering an ISO 6 environment will require at least one airlock (the recommendation is two). This adds wall partitions, doors, ceilings… and therefore increases the cost.

The size

The bigger the room, the lower the cost per square foot. This is down to economies of scale. For a large cleanroom, it costs less per square foot, but more in total, since there are more square feet involved.

Using fume hoods/biosafety cabinets

If a fume hood exhausts air to the exterior of the building, that exhausted air will need to be replaced with fresh air. This fresh air will need to be conditioned (temperature and relative humidity). This requires a larger air make up or air handling unit.

Addition of fume hoods and safety cabinets affects air requirements and costs

Monitoring system

To meet most industry regulations and standards, there must be a record of the conditions within the cleanroom. Will this be a manual system written by hand or automated? Monitoring system costs can range from $500 to $20,000 plus.

The installation space and location

Undoubtedly, the distance from the cleanroom manufacturing facility to a site will influence the price. If installation is included in the price per square foot, the cleanroom manufacturer must estimate the time and level of difficulty of installation. To do so, they must know everything about the location:

- What is the space like?

- Are there obstacles?

- What is the height below the trusses?

- Are there any columns?

- What is the existing floor, is it concrete?

- Is it levelled?

- What power is available (1 phase or 3 phases)?

- How accessible is the available space?

We once shipped a cleanroom to a sixteenth floor in downtown Toronto. We had to close the street, get an escort and a crane to lift up the panels to the sixteenth floor and then pass them through the windows. This is an extreme situation but clearly with this particular project compared to a simple installation in an empty warehouse, there is a major price difference.

Also, what is the temperature / humidity control like in this space in the building — is it heated in winter and conditioned in summer? Otherwise the HVAC will have to work harder to keep the environment controlled.

Utilities and access panels in the walls

What services will the process require? Plain empty cleanroom panels are cheaper than utilities-ready ones. If three power outlets are needed versus 40, we are not talking about the same price. Utilities include power receptacle (120 v, 208 v, 240 v, 600 v…), plumbing (hot / cold water, deionised water), compressed air, etc.

The high-end look

There are different models of air return grilles, windows, doors, etc.

Doors and windows — the number, the size and the type of windows impact the cost per square foot, as does the type and number of doors (full flush or semi-flush). The price will also differ if full flush or semi-flush mount windows are chosen. The same applies with the magnetised air return grille for a fully flush option.

The number, size and type of windows and doors will impact the cost per square foot

Lighting system — the required level of lighting will also affect the price, depending upon whether the cleanroom needs to achieve 300–1,200 lux. There are also various lighting system options, ranging from the standard lighting to the full flush lighting accessible via the roof, which enables the lights to be changed from outside of the clean envelope, reducing maintenance and cleanroom downtime.

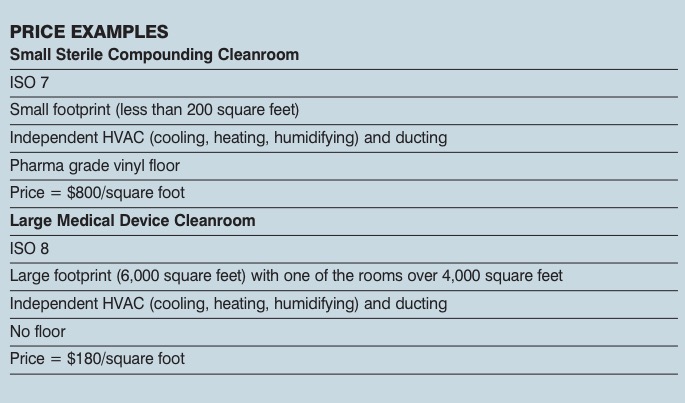

Price examples

For easy comparison, price examples for two cleanroom projects at opposite ends of the spectrum are given above. Both projects are turnkey and include engineering, the envelope (walls, ceiling, doors...), the HVAC system and installation.

To find out more information about costing a cleanroom click here for the original article on the Mecart website.