The benefits of the Design/Build (DB) approach and its advantages over the conventional Design/Bid/Build (DBB) approach have been well known for decades when it comes to realising new facilities for cGMP manufacturing in the biopharma industry. With the increasing industry demand for compressed schedules, reduced total costs, and improved quality of construction, it is somewhat surprising that the traditional DBB methodology is still favoured by manufacturers (owners) building new facilities.

The COVID-19 pandemic and need for new manufacturing capability for vaccines and therapeutics has not only reinforced the need for the DB methodology but has in fact shown that more innovative Pre-Design/Prefabricate (PDPF) approaches to new facility construction can be impactful in addressing the industry's growing need for more rapidly deployable manufacturing capacity.

The competitive market forces resulting from the DBB approach can encourage companies to "low-ball" their bid to win the contract

And while these approaches are not necessarily new, and the benefits have been realised by owners who understand their value, there has been resistance and barriers to adoption that have driven many owners to maintain the status quo and not move away from the traditional DBB method. These barriers and the reasons for resisting proven approaches need to be understood to overcome them.

There are three main project delivery methodologies; DBB, DB and PDPF.

Design/Bid/Build

Following the DBB method, which is the most traditional approach within the construction industry, the owner contracts separately with individual design and construction firms. This typically requires a bidding process to hire the design firm at the start of the project and another bidding process at the end of design to select the general contractor for construction.

Many owners will also go through a bidding process for each of the individual phases of engineering design including Concept Design, Basis of Design, and Detailed Design. Because there is not a contractual obligation between the selected design firm and the construction firm, and there is no input from the construction firm on the design, the owner carries all of the risk associated with the engineering design that is handed over for construction.

Design/Build

Following the DB method, the owner hires one company to execute both the facility design and construction such that the project delivery is managed through a single contract with a DB firm. Typically, there will be single bidding process by the owner before the start of the project to select a DB firm who, once selected, will develop the design based upon the owner defined user requirements and performance specifications for the facility with input from its integrated construction team. The DB contractor retains its own architect, engineers, and consultants in support of the design development effort, some of which may be part of the contractor's own organisation or sub-contracted if the expertise is not available to them internally.

There are several companies, such as IPS Engineering, that provide EPCMV services (Engineering Procurement Construction Management Validation) and have the internal staff, experience and resources to support all phases of a project up to and including validation.

Pre-Design/Prefabricate

The PDPF approach builds upon the DB method but also leverages the benefits of standardised pre-engineered platform facility designs and off-site manufacturing to minimise on-site construction activities.

The platform designs can be for the entire facility or for the critical process areas and are engineered for specific applications such as mAbs, Autologous Cell Therapies, Drug Product Filling, etc. Prefabricated modular solutions, which are built in a factory and then shipped to the site for final assembly and qualification, can be implemented for shell building structures, cleanrooms, and utility systems.

G-CON Manufacturing's autonomous POD cleanroom systems are an example of a prefabricated modular solution currently being utilised within the industry. G-CON and IPS Engineering have also collaborated to develop iCON, a turnkey facility platform which is based on the PDPF approach.

The advantages

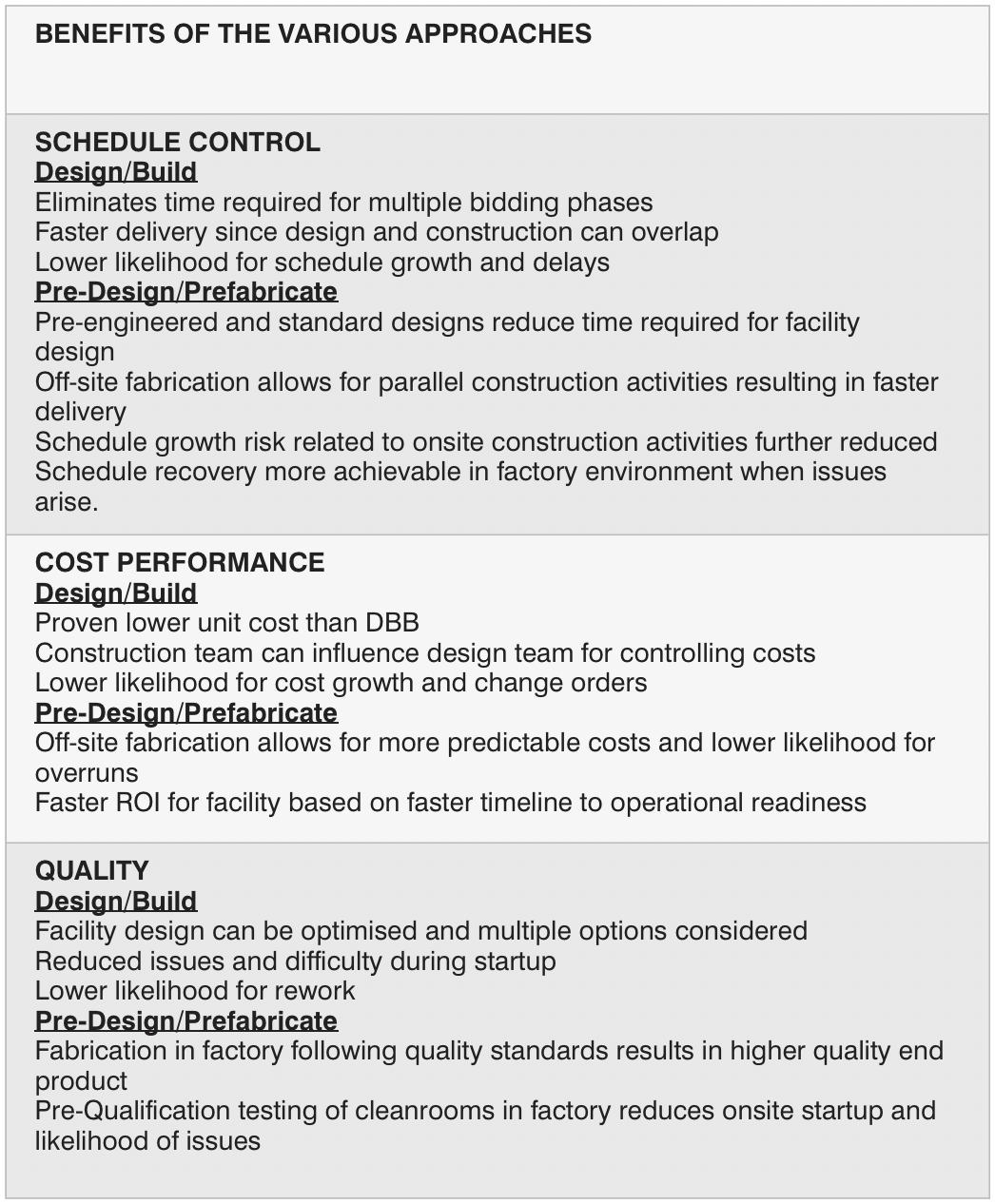

Over the past 25 years, there have been several independent studies performed by trade organisations like the Construction Industry Institute (CII) and International Group for Lean Construction, as well as by some universities such as Texas A&M University, University of Texas, and Penn State University, that have all confirmed the benefits of the DB approach over DBB about schedule control, cost performance, and quality outcome.

These benefits, summarised in the box, are primarily driven by more collaborative and reliable project execution where both the design and construction teams are obligated contractually to work together in the best interest of the project. The PDPF approach further improves upon the benefits by taking advantage of standardised design platforms and off-site fabrication that is performed within a well-controlled factory environment, by experienced and trained staff, following operational and quality system procedures. These additional benefits are italicised in the box.

Figure 1: Design/Bid/Build vs Design/Build

With the proven benefits of the DB and PDPF approach, it is difficult to understand why so many companies still choose to utilise DBB today. The simple answer is that historically it has been the most utilised methodology, the one upon which the construction industry has largely been built upon, and most owners are familiar with. Publicly funded government projects are required to follow this approach with the intent of soliciting fair and competitive bids to achieve the required project delivery and outcome and based on awarding the project to the lowest bidder.

Many companies have built their corporate procurement processes around the DBB approach to obtain the lowest pricing and incentivise their procurement teams to push for additional discounts once they have narrowed down the bid list. The competitive market forces resulting from this approach can encourage construction companies to "low-ball" their bid to win the contract, with the intent of recovering the revenue through change orders they push on the owner through the life of the project. This is not in the best interest of the owner and ultimately can foster delays, distrust and unwanted chaos through the life of the project.

Figure 2: Delivery of Prefabricated Modular POD Cleanroom

While these types of procurement practices may be effective for the repeatable purchase of consumables and raw materials, they are not necessarily the best approach for capital projects where procurement's incentives are based primarily on up front capital cost reduction only and not fully aligned with the incentives and goals of other stakeholders on the owner side (e.g., engineering, operations, quality). The success of the project outcome is determined by the construction company selected and this is, therefore, often based upon which group on the owner side has the most influence and authority during the selection process.

Conclusion

Resistance to change is often the biggest obstacle to innovation and to enabling an effective transition away from the traditional ways of doing things. And the biopharma industry has historically been slow to adapt even when the benefits of new methodologies and approaches are proven. The past 18 months have proven that change in our industry is needed and its ability to respond more rapidly to global situations and market conditions is critical, especially when it comes to establishing new manufacturing capability and capacity. The benefits of Design/Build and Pre-Design/Pre-Fabricate approaches for constructing new facilities have been proven and can provide a pathway for the industry to leverage as it moves into the future.

To fully realise the potential, drug manufacturers must rethink and retool their capital procurement processes to better align with the overall project objectives as well as their internal goals and incentives.