It’s no secret that COVID-19 has drastically impacted the world around us. Throughout August 2021, the illness has overrun hospitals. To combat the spread of COVID-19 amongst hospital staff and patients, hospitals have been paying extra attention to their contamination control procedures. Aside from HEPA filters, hospitals have been using a piece of cleanroom technology to contain the illness in the hospital to protect the staff.

So what’s the secret? Pressurised rooms!

There are two types of pressurised rooms: negative and positive. Both are used in hospitals and cleanrooms, but we’ve seen a massive increase in the use and demand of negative pressure rooms during the pandemic.

Negative Pressure Rooms

In a negative pressure room, the air inside the room is kept at a lower pressure than the air outside the room. Since the atmosphere seeks to stay in equilibrium, when the door is opened, the air rushes into the room to try to equalise the pressure. Thus, all the germs are kept inside the room.

In cleanrooms, we will occasionally see negative pressure used, although positive pressure is more common. We will use negative pressure when we have to keep contaminants inside the cleanroom. This can be applicable in some pharmaceutical and laboratory applications where the contents being studied could be harmful outside of the cleanroom.

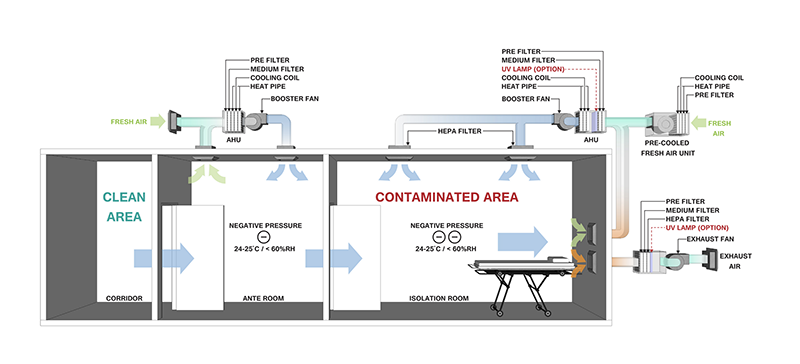

We usually recommend some form of anteroom for gowning and safely moving in and out of the room. This anteroom would also serve the purpose of helping to equalise pressure without allowing air to rush into the cleanroom, carrying in contaminants.

How are negative pressure rooms used to fight COVID-19?

Negative pressure rooms are not just used to combat COVID-19 spreading in hospitals, but are a common practice when a patient has a highly infectious disease. These illnesses can include measles, tuberculosis, SARS, MERS, COVID-19, and more.

Negative room pressure

These negative pressure rooms are often called “isolation rooms”. Since the air rushes into the room when a door is opened, the germs all stay inside the room with the patient.

Typically, when a patient is kept in a negative pressure room, their illness is more dangerous to the outside world than outside germs are to them. Thus, it’s important to protect the staff and other patients from breathing the same air as the sick patient.

The air in these rooms is monitored and regularly changed. The CDC recommends changing the air 12 times per hour. When the air leaves the room, it must go through a HEPA filter before recirculating throughout the hospital.

Many hospitals had some negative pressure rooms before the pandemic, but COVID-19 forced hospitals to hastily build more. As we see surging numbers, the demand for these rooms has skyrocketed, but we simply cannot build them fast enough.

The hospitals are pairing negative pressure rooms with a positive pressure portable anteroom. This anteroom allows staff to safely put on personal protective equipment (PPE) before entering the room.

This piece of cleanroom technology, though, has been instrumental - especially at the start of the pandemic - for isolating COVID-19 patients to slow the spread.

Positive Pressure Rooms

Positive pressure rooms are the opposite of negative pressure rooms - and are a common piece of cleanroom technology. The air pressure inside the room is higher than the pressure outside the room. So when a door is opened, the air rushes outside of the room, carrying out particles and germs.

In hospitals, positive pressure rooms are used to protect critically ill and immunocompromised patients. Since the air is forced out through the door, there is too much pressure leaving the room for it to re-enter the room. The air is unable to recirculate, so it protects the patient from pathogens and germs from outside the room.

In this case, the patient needs more protection from what’s outside than the people on the outside need from the patient’s germs. As mentioned previously, though, positive pressure technology is also used in the antechambers for negative pressure rooms.

How are positive pressure rooms used in cleanrooms?

Positive pressure is a common technique used to control contaminants entering a cleanroom. All air entering a cleanroom should go through the proper filters and systems to make sure that as few particles as possible from the outside environment enter the cleanroom.

Thus, positive pressure is the optimal technique used to push the particles inside the cleanroom out of the room when a door is opened. This also makes it the optimal technique for pressurising an anteroom.

Positive pressure cleanrooms are commonly used in several industries, including electronics, food processing, military and defense applications, automobiles, and more.

Cleanroom technology impacts our lives everyday

Cleanroom technology simply epitomises contamination control. Every day, we see and use contamination control, but COVID-19 has made this even more evident.

In cleanrooms, we see contamination control at a very strict level, with full gowning protocols, face coverings, filtered air, and strict regulations around what is allowed inside the cleanroom.

During the pandemic, we’ve seen contamination control in the frequent hand washing and sanitizing, face coverings, social distancing, and more.

What do both have in common? We are attempting to control particles.

Here at Lighthouse Worldwide Solutions, we are clean air and particle experts. Monitoring particles is what we do. We are dedicated to setting industry standards and best practices for developing cleanroom technology, monitoring particles, and keeping cleanrooms clean. To help you make the most of your cleanroom and keep up with industry best practices, we’ve put all our resources together in one spot.

Today, you can create a free account and access valuable video training, product breakdowns, industry trends, and more!