High-purity gases critical to the semiconductor manufacturing environment are increasingly sought-after to meet ever-higher production yields and quality thresholds. The speciality gases involved are either ultra-high purity (UHP) single-component gases or accurately prepared gas mixtures.

As the industry drives towards the production of smaller chip sizes, it leads to the requirement for UHP gases to achieve higher levels of purity, with the utmost reliability. For some foundries or fabs, this has made it necessary to install captive air separation units (ASUs) in a bid to produce and monitor costly materials in-house and reduce scrappage.

Whether they are supplied from on-site ASUs, bulk tube trailers or bulk tanks, these gases must be monitored at their point of production or entry to the facility to ensure the necessary purity.

During wafer production, excess chemical reactants and products may deposit on the substrate and other equipment. Because of the sensitive dimensions of electronic devices, even small particles can ruin the devices under fabrication.

To prevent contamination of the wafer by environmental factors, it is essential to analyse all the gaseous and liquid media for impurities

Semiconductor fabs must, therefore, monitor the entire wafer manufacturing environment, controlling and analysing any substance that the silicon is exposed to; the gamut from rinsing agents and chemical reagents used to clean surfaces, to inert and reactive gases used during every process step such as implantation and deposition. It also applies to the air in the cleanroom and in select environments throughout the manufacturing procedure.

To prevent contamination of the wafer by environmental factors, it is essential to analyse all the gaseous and liquid media for impurities.

Gas monitoring

To avoid, or at least minimise wafer contamination, fabs employ a variety of resources, including strict gas supplier specifications, multiple gas purification techniques as well as real-time continuous gas purity monitoring and post-process inspection to ensure UHP gases are delivered to the manufacturing procedure.

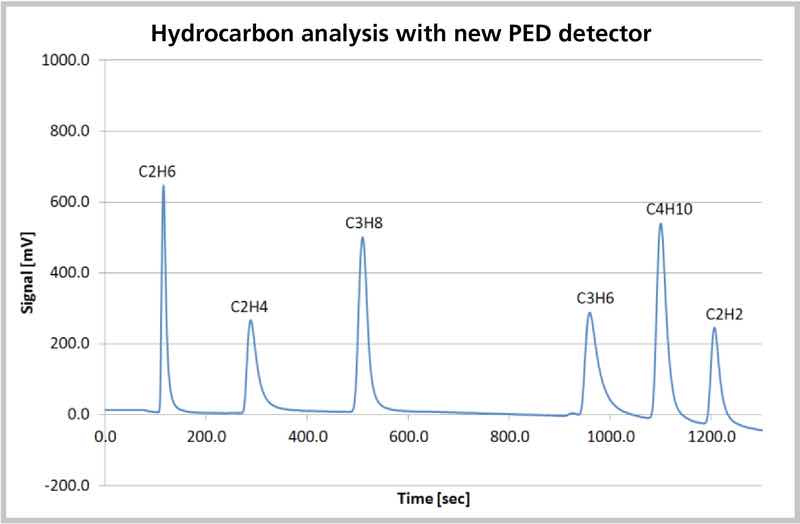

The chromatogram shows sensitivity to hydrocarbons and CO2 achieved without the use of a methaniser that converts CO and CO2 to CH4. While a methaniser is always required to measure CO and CO2 with an FID sensor, it is not required by the PED

Incidents of batch scrappage, however, remain frequent and can have a long-term impact on both the market supply and the manufacturer’s revenue streams.

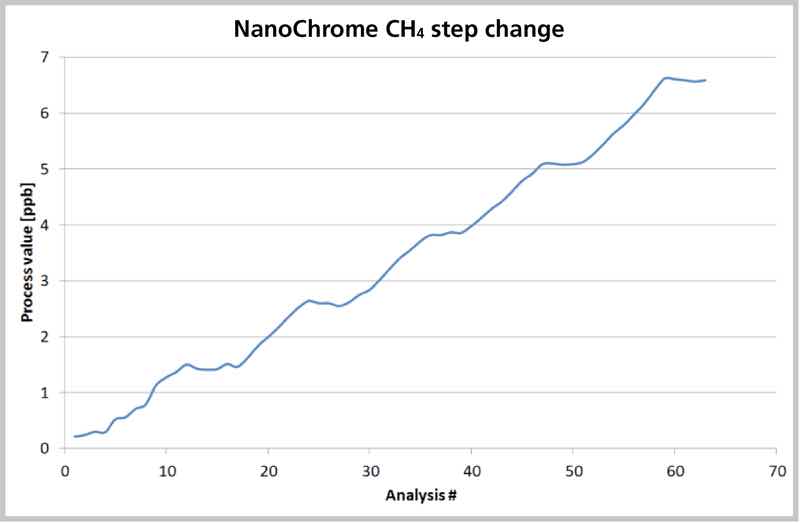

A step response using a SERVOPRO NanoChrome analyser at ppb level showing

the sensitivity achieved with this sensor

UHP gases are designed to meet a specific purity grade from the industrial gas supplier but are typically also monitored at their point of production or entry into the facility. As a result, a full set of analysers can typically be found at fabs at every point of use, each costing thousands of dollars.

It is common to have 10-20 analysers installed in a stationary analytical system to monitor bulk gases at the post-purifier stage. Each system is integrated and digitally connected to the building management system to collect and trend gas purity data.

The monitoring challenges

The speciality gases required during wafer manufacture include high-purity air-separated gases, noble gases, ammonia, hydrocarbon gases, and halogen gases.

These gases require rigorous chemical analysis to ensure their composition meets stringent specifications, particularly for the detection of moisture and oxygen impurities that can contaminate the gas during transportation or the production process. Even if only present in ultra-trace quantities, these impurities can void an entire batch of products; therefore rigorous analysis is required to the lowest detection levels possible.

For oxygen, exceptionally low parts-per-trillion (ppt) measurements are required to maintain gas purity. Such a measurement is achievable with only precise oxygen sensing technologies. For example, Servomex’s DF-550E and DF-560E analysers use a non-depleting Coulometric sensor to measure down to 200 ppt and 45 ppt, respectively. This technology delivers a direct, safe O2 measurement, rather than using unwieldy catalytic processes that require flammable hydrogen to function.

Ultra-trace moisture measurements are best achieved by using Tunable Diode Laser (TDL) technologies, such as those in Servomex’s DF-700 series. The equipment utilises a non-contact laser measurement to locate moisture as a contaminant in electronics-grade nitrogen (N2) hydrogen, (H2), helium, (He) and argon (Ar).

Measurements for a range of other potential gas contaminants are available via gas chromatography methods. Such contaminants include Ar, N2, H2, carbon monoxide (CO), carbon dioxide (CO2), methane (CH4) and other hydrocarbons.

With a diverse range of sensors available on the market to cover a widespread set of measurements, each sensor has advantages and drawbacks. A solid understanding of the different technologies is critical.

Gas measurement technologies

Thermal conductivity detection (TCD), flame ionisation detection (FID) and reduction gas detection (RGD) are the most widely used gas measurement technologies to date.

Commonly used for hydrocarbon analysis, FID sensors are favoured for their simplicity and offer a highly selective and linear measurement over TCD sensors, which are in comparison lower in sensitivity and require a costly larger sample size.

The best FID sensors achieve a lower detection limit (LDL) between 10 parts per billion (ppb) and 20 ppb methane equivalent, which is usually acceptable for general gas (G- Gas) made before the main purifier.

The FID sensor does, however, require carrier gas, fuel and air to operate, which makes it more prone to noise from low-level hydrocarbon contamination from those three potential sources. More crucially, this sensor type requires a flame to burn air and hydrocarbon- free hydrogen fuel gas, increasing operator safety concerns.

The best FID sensors achieve a lower detection limit (LDL) between 10 parts per billion (ppb) and 20 ppb methane equivalent

In addition, the pure gas (P-Gas) used inside the fab after the purifier stage requires a much lower LDL requirement of less than 1 ppb, making the FID sensor a less than ideal tool to work with.

RGD sensors are used to measure H2 and CO impurities at low ppb levels. The impurities reduce mercuric oxide to mercury vapour, which then absorbs ultraviolet (UV) light from a mercury lamp. The change in light transmittance provides a measure of the H2 or CO concentration.

The technique provides a sensitive measurement with an LDL below 1 ppb. However, the output of the UV lamp diminishes over its lifetime reducing the sensitivity of the sensor. The UV lamp also has a short operating life, and its frequent replacement means the cost of maintenance is high.

Reaping the benefits of PED

Challenged to find a more comprehensive solution for monitoring UHP trace gases beyond oxygen and moisture, Servomex’s R&D team undertook extensive research on its existing Plasma Emission Detection (PED) technology, aiming to identify a configuration specific to hydrocarbons, while avoiding the use of flammable gases, as well as H2 and CO.

The intensive research has led to the development of a single-supplier solution that satisfies the high-precision trace analysis for the demanding environment of wafer production. Servomex believes this is a unique offer in the UHP gas purity measurement market.

With the new equipment, measurements are extended to include H2, CH4, non-methane hydrocarbons (NMHC), CO2, and CO—with no need for a methaniser

Servomex developed a new PED sensing technology, highly selective to any molecules containing carbons (organic or inorganic) and capable of achieving up to 100 times more sensitivity than an FID measurement, depending on the carrier gas.

Ultra-trace moisture measurements are best achieved by using Tunable Diode Laser (TDL) technologies, such as those in Servomex’s DF-700 series

As the PED sensor requires only a carrier gas, external contamination from air and fuel is removed. While it's still very important to have a clean carrier gas, techniques exist to obtain a clean helium or argon carrier gas with a total impurity level below 1 ppb. Avoiding the use of hydrogen and air reduces the cost of ownership; less gas is consumed so fewer purification systems are required.

Able to measure ultra-traces of argon (Ar) and nitrogen (N2), this sensing technology was integrated into the development of a new analyser: the SERVOPRO NanoChrome. With the new equipment, measurements are extended to include H2, CH4, non-methane hydrocarbons (NMHC), CO2, and CO—with no need for a methaniser.

With no requirement for a flammable fuel gas or frequent maintenance, the Servomex PED sensor also increases safety, lowers operational costs, and reduces downtime.

The analytical sensitivity and reliability of the NanoChrome are enhanced by advanced signal recovery, utilising specially developed adaptive chromatographic filtering methods and patented detection techniques for a more selective measurement than previously available for UHP gases.

By utilising a direct analysis methodology, the NanoChrome removes the doubt associated with measurements made by FID and other reduction gas detection measurements.

The Servomex research team strove for an “exact fit solution” to the analytical needs, rather than a "next best option". Alongside radically improved PED sensing technology, it developed new ProPeak processing software, as well as methodologies to interpret and process data. The result is a fast and highly accurate solution that fits the gap in UHP gas analysis.

N.B. This article is featured in the July 2019 issue of Cleanroom Technology. Subscribe today and get your print copy!