2025 marked another exciting year of growth for AST, as the life sciences industry at large continued to focus on realizing innovative sterile drug products with advanced, streamlined technologies. AST followed up a groundbreaking 2024 with a continued focus on modular, standardized solutions, cGMP strategies and guidance, and insights into the latest developments and trends across pharmaceutical manufacturing.

Strategic partnership with Marchesini Group combines expertise and technology to accelerate growth in aseptic manufacturing

The year concluded on an exciting note as December saw the landmark announcement of a strategic partnership between AST and the Marchesini Group, a leader in pharmaceutical packaging machinery.

With the combined expertise and technology of the two companies, the partnership will enable the development of sophisticated solutions, guided by a common vision: creating value for customers, expanding market presence globally, and promoting innovation.

Team activity

The AST team was once again globetrotting this past year, connecting with friends and colleagues at exciting industry events, including PDA Week, PharmaPack 2025, CPHI, and INTERPHEX Global.

INTERPHEX once again stood out as a highlight of 2025, and AST was excited to showcase our newest drug manufacturing solutions, including the launch of a new integrated, fully automatic GENiSYS C filling line, presented in collaboration with Ascend Advanced Therapies, who are set to install the line at their Alachua, Florida, facility.

INTERPHEX week was especially significant for the AST family as April marked our 60th anniversary as a company. AST also won an exhibitor award for the second consecutive year, as INTERPHEX staff and conference partners selected AST as the 2025 Efficiency Champion for our digital twin solution. The award identifies products or services that make drug development processes more efficient and deliver substantial time savings for crucial aspects of drug manufacturing.

AST team growth

The team at AST continued to make additions in 2025, expanding expertise and key leadership roles. The Executive Team welcomed Jacob Stephen as Chief Operating Officer and formally introduced Charisse Curtis as Chief Commercial Officer. AST also continued to reinforce its cGMP expertise with the addition of industry veteran Jason Rossi as Principal CQV Engineer.

Friendly new faces were also welcomed across various teams, including Engineering, Operations, Customer Care, and Business Development, as AST continues its exciting trajectory into 2026.

Product and service advancements

AST continued its focus on leveraging advanced technical solutions, coupled with end-to-end services, to deliver proven, turnkey solutions for the drug product manufacturing journey.

AST Academy

Across the life sciences, there’s a clear focus on implementing holistic approaches to drug development that consider quality and compliance from the start, and ultimately result in improved time-to-market for safe, effective sterile medicinal products. In 2025, AST was thrilled to introduce AST Academy as a comprehensive cGMP program that covers the full scope of tasks and knowledge areas aseptic processing professionals encounter on a daily basis.

With the rollout of AST Academy, AST now offers customers the expertise and resources needed to navigate the CQV landscape and provides quality-based solutions that support a faster path to production.

Read CCO Charisse Curtis’s and Principal CQV Engineer Jason Rossi’s takeaways on how this service expansion meets industry needs, and what customers can expect from the extensive training and resource platform.

Leveraging the latest in decontamination technology through a forward-thinking partnership

AST has leveraged the innovative application of 7% Vapor Phase Hydrogen Peroxide in isolator decontamination. This groundbreaking technology, implemented in partnership with leading experts CURIS Decontamination System, provides pharmaceutical manufacturers with an advanced, validated fill-finish solution that includes:

-

Industry-leading cycle times with aeration in as little as 15 minutes

-

Improved levels of operator safety

-

Expanded material compatibility

-

Increased equipment uptime and lifespan

This fully automated system utilizes real-time feedback for precise and repeatable 6-log reductions, and offers 100% integration with AST’s Atmos™ isolator for a complete turnkey solution. Explore the partnership between the two technology leaders.

Introducing an advanced wireless glove testing solution

AST unveiled Shield® GIT, an advanced, fully integrated wireless glove-testing system that prioritizes operator safety, product integrity, and regulatory excellence. As part of an active contamination control strategy, this glove testing system provides operators with the tools necessary to validate quickly and maintain complete records, data, and peace of mind over the life of your gloves.

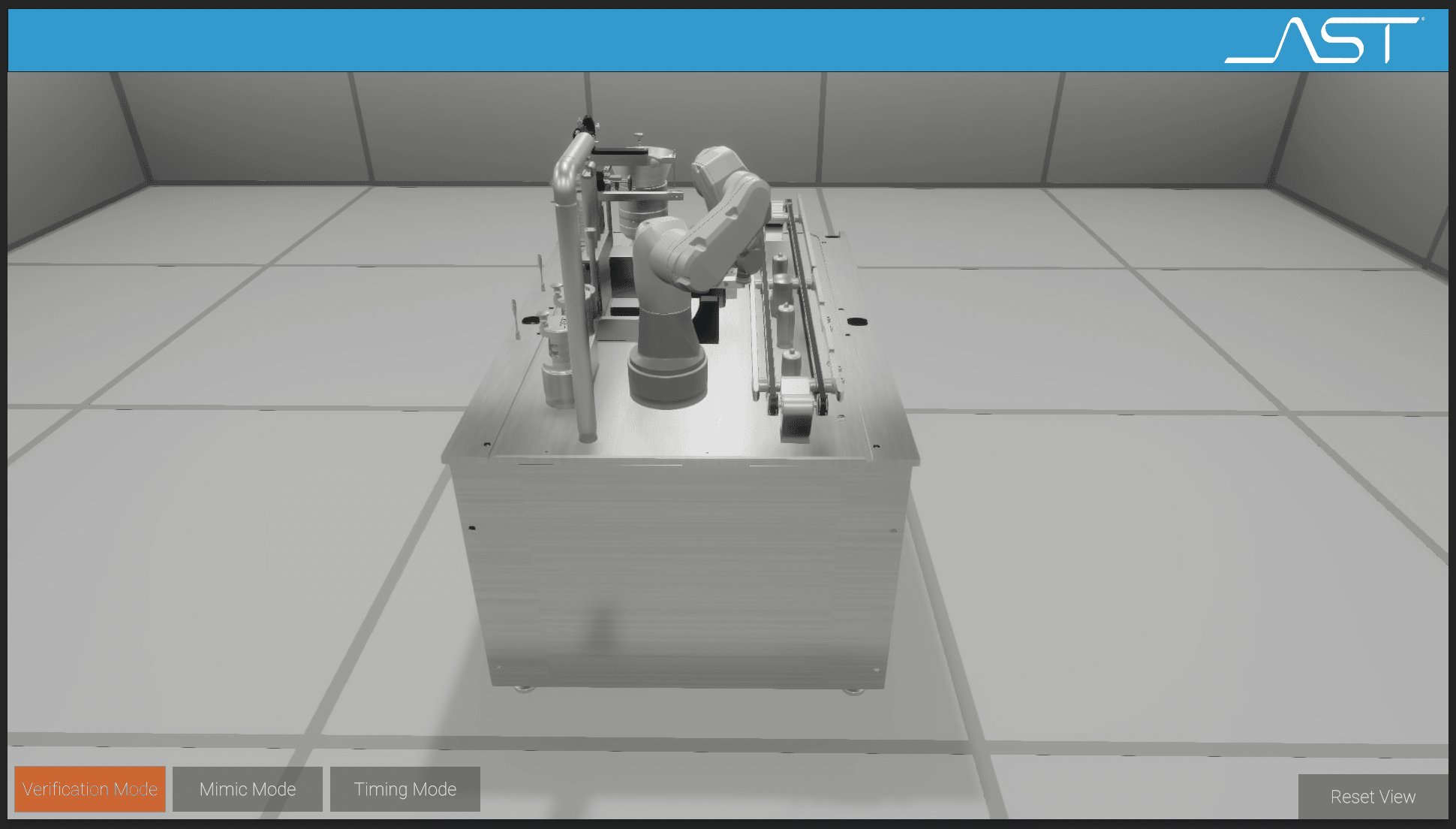

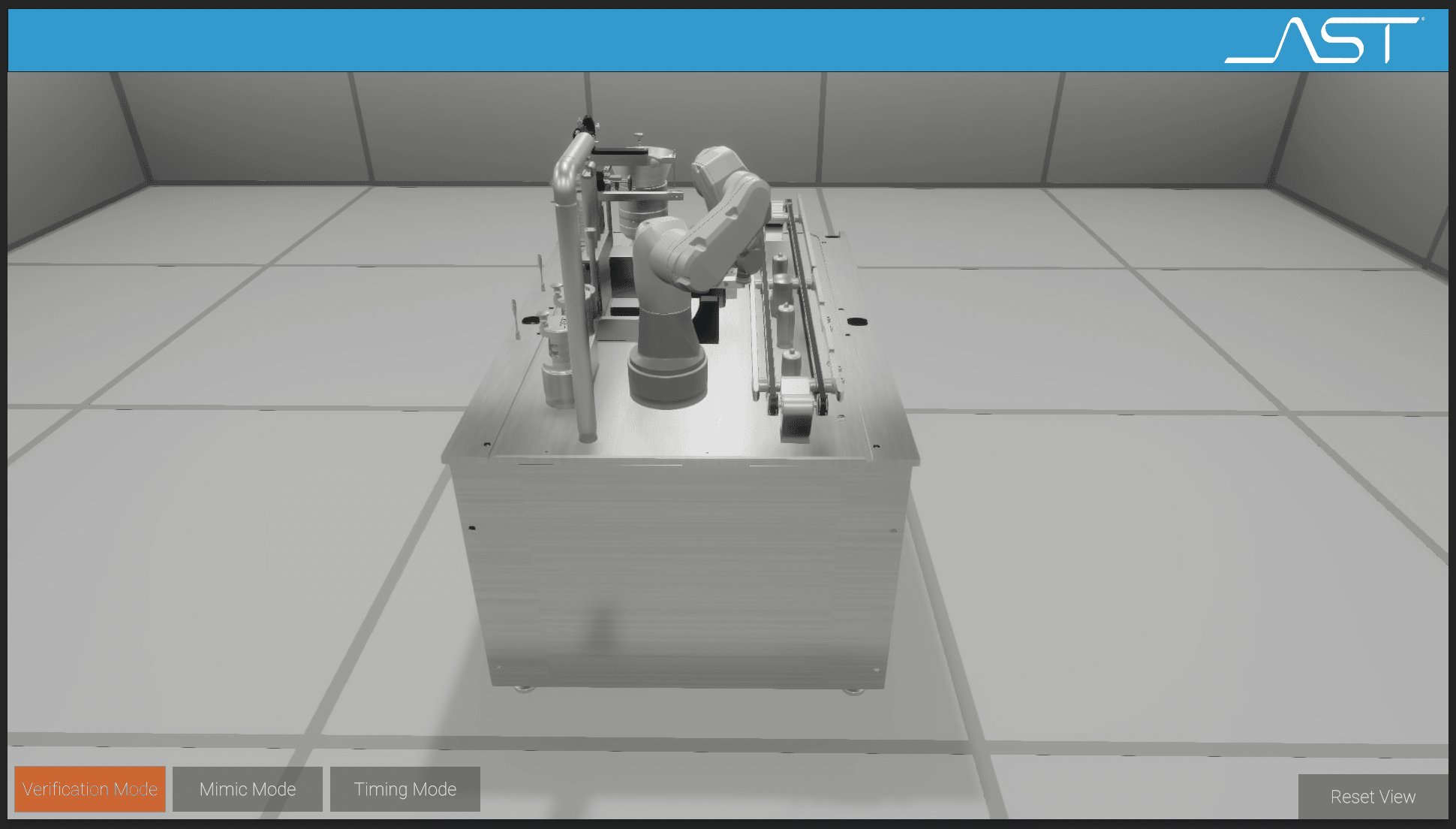

AST’s digital twin tool

AST introduced its digital twin tool, which offers key process, quality, and data efficiencies at every stage of the drug product lifecycle. Digital twin is a dynamic virtual model of a specified fill-finish machine that synthesizes real-time data, physical operations, and virtual environments in an exact digital replica of a machine, system, or complete manufacturing operation. AST’s digital twin tool consists of three parts: the physical machine, all data and parameters that influence or are generated by that machine, and the digital environment where the “twin”—the exact digital replica—exists.

The innovative integration of the physical, digital, and data spaces offered by digital twin provides exciting possibilities for the production of liquid pharmaceuticals at every stage of drug development through to commercial manufacturing.

Thought leadership on the latest breakthroughs for pharmaceutical manufacturing

Our team has had the exciting opportunity to write and speak for various industry functions, publications, and events in 2025, as AST continues to contribute to important conversations around product safety and efficiency, regulatorily robust solutions, and the future of pharmaceutical manufacturing.

ISPE Annual Meeting & Expo

At the 2025 ISPE Annual Meeting & Expo, AST VP of Technical Sales Josh Russell and Principal CQV Engineer Jason Rossi presented on the development and application of 7% Vapor Phase Hydrogen Peroxide (VPHP) for decontamination in aseptic isolators. The session covered design considerations, validation protocols, and performance data across multiple isolated filling line configurations. Josh and Jason explored how low-concentration, rapid VPHP technology addresses traditional challenges, such as downtime, high-concentration risks, and off-gassing, while maintaining sterility assurance. Data showed that the decontamination solution achieved >6-log reductions and highlighted expanded material compatibility, reduced machine downtime, and improved safety in automated fill-finish operations. Listen to the presentation here.

AST’s CTO on Pharma 4.0 and digital twin technology

What is the future outlook for digital and data-driven solutions and implementation in the pharmaceutical manufacturing industry? How can we effectively interpret the principles of Pharma 4.0 and apply them to real-world parameters and scenarios? In the October 2025 issue of Cleanroom Technology, AST CTO Steven Ng explored the latest exciting Pharma 4.0 developments, including digital twin technology, and detailed guidance on assessing pharmaceutical manufacturing operations for real-time technological solutions and digital optimization. Read the full article.

AST technology: prioritizing First Air

How do the First Air principle and isolator technology fit together in the context of the revised Annex 1? What role does airflow visualization play, and how can it improve the design process for aseptic operations? AST’s Joshua Russell examined these questions and more in the February 2025 issue of Cleanroom Technology, as he discussed the heightened requirements for product integrity and regulatory compliance in pharmaceutical manufacturing. Read the full article here.

A primer on environmental monitoring and contamination control strategy

How do you optimally design a filling line to best integrate environmental monitoring technology? What’s the best strategy for implementing EM operations and interventions in a way that minimizes contamination risks and supports machine uptime? AST’s Jason Rossi and Particle Measuring Systems’ Marc Machauer discussed these questions and more in this in-depth webinar: Automated Active Microbial Collection in Aseptic Filling Lines.

White paper on zero-waste approaches for sterile injectable manufacturing

What are the keys to stewarding a product during the sterile filling process? This AST white paper, Scaling to Patient-Centered Medicine: Automation, Robotics and Implementing Real-Time IPC, delves into various approaches to in-process weight checks for fill-finish, as well as industry insights on meeting the latest quality demands for drug product manufacturing.

Learning highlights include:

-

The history of quality control measures

-

Implementing zero-waste strategies for fluid handling and dispensing

-

Approaches to IPC for high-value, targeted parenteral products

-

AST’s Augmented IPC, an advanced process solution that executes 100 percent IPC with minimal compromise to machine speed

Download the white paper and check out our resource page, including FAQs and a video overview of IPC across AST systems here.

Honoring our history and celebrating new beginnings

Marking 60 years of AST with a revitalized mission, vision, and purpose

In April of 2025, AST marked its 60th anniversary—six incredible decades of teamwork, ingenuity, and advancements in automated manufacturing solutions. The passion and determination that initiated our founding continue to drive us today, as we deliver innovative drug manufacturing solutions for the life sciences industry.

As part of our 60th anniversary, AST introduced a reenergized Mission, Vision, and Purpose, built on our ongoing commitment to innovation and a customer-focused approach. CEO & President Joe Hoff spoke on the importance of these statements, the storied history of AST, and the amazing AST team that makes the pursuit of intelligent, intuitive, and innovative drug product manufacturing solutions possible.

2025 was truly one for the books, and the AST team is more excited than ever to embark on another year of serving our valued customers with intelligent, innovative, intuitive solutions for drug product manufacturing.