In the realm of healthcare and cleanroom environments, maintaining precise control over air pressure is crucial. This control ensures the safety of patients, staff, and sensitive equipment by preventing contamination and the spread of airborne pathogens.

Air pressure stabilisers play a pivotal role in achieving and maintaining optimal air pressure conditions, thereby enhancing the quality and safety of these environments.

Understanding air pressure stabilisers

Air pressure stabilisers are sophisticated devices designed to regulate air pressure within enclosed spaces such as hospitals, laboratories, pharmaceutical facilities, and cleanrooms.

Air pressure stabilisers play a pivotal role in achieving and maintaining optimal air pressure conditions

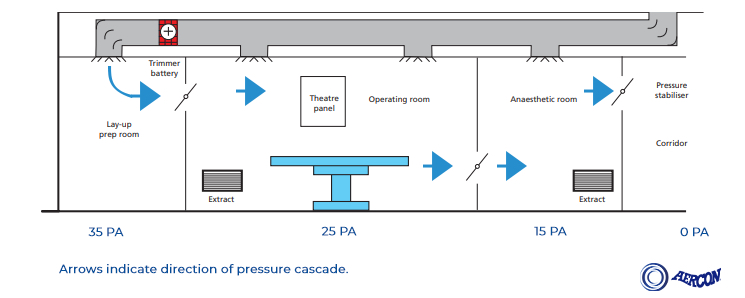

Air pressure stabilisers operate on the principle of differential pressure control. They help to maintain a pressure gradient between adjacent spaces, ensuring that air flows from clean to less clean areas, thereby preventing the ingress of contaminants.

By maintaining positive pressure in critical environments and negative pressure in areas where contamination must be contained, these devices uphold stringent cleanliness standards.

Infection control

In healthcare facilities, preventing the transmission of infectious diseases is paramount. Air pressure stabilisers contribute significantly to infection control by establishing and maintaining controlled environments.

Positive pressure rooms, commonly found in operating theatres, isolation units, and critical care areas, prevent the entry of airborne pathogens from surrounding areas, reducing the risk of hospital-acquired infections.

Pressure stabilisers play a pivotal role in creating and sustaining the required pressure differentials

Negative pressure rooms, on the other hand, are essential for isolating contagious patients and containing airborne contaminants. They are typically utilised to ensure infectious particles do not escape into the surrounding environment, safeguarding both patients and healthcare workers.

Pressure stabilisers play a pivotal role in creating and sustaining the required pressure differentials, thereby fortifying infection control measures.

Enhanced air quality

Clean, fresh air is vital for patient recovery and staff wellbeing. Air pressure stabilisers assist in the continuous circulation of filtered air, aiding in the removal of airborne pollutants, allergens, and pathogens.

Air pressure stabilisers play a pivotal role in maintaining the efficiency of healthcare facilities such as cleanrooms

By maintaining optimal air quality, air pressure stabilisers contribute to a healthier and more comfortable environment for patients, visitors, and healthcare personnel.

Regulatory compliance

Healthcare facilities are subject to stringent regulatory standards and guidelines aimed at ensuring patient safety and quality of care. Adequate pressure control, as facilitated by air pressure stabilisers, is a fundamental requirement for compliance with these regulations.

By adhering to regulatory standards, healthcare institutions demonstrate their commitment to maintaining high standards of cleanliness and patient safety.

Maintenance and servicing

To maintain the operational efficiency of an operating theatre, it is imperative to conduct annual verification. This verification process should adhere to the guidelines outlined in HTM 03-01, which specifies the annual checking and cleaning of air pressure stabilisers.

It is advisable to review your verification reports periodically to confirm that your air pressure stabilisers are functioning in line with their original specifications.

Air pressure stabilisers play a critical role in maintaining the pristine conditions required within cleanroom environments

Air pressure stabilisers play a pivotal role in maintaining the efficiency of healthcare facilities such as cleanrooms.

The potential issues that could be caused, i.e. over/under-pressurisation of rooms, disruption of the sterile environment, and potential risk to patients’ health, if pressure stabilisers are not functioning appropriately cement their vital requirement in the healthcare setup when pressurised rooms are necessary.

An example of a pressure cascade in a cleanroom

Applications in cleanroom environments

Cleanrooms are specialised facilities used in industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, and aerospace engineering, where even minor contaminants can compromise product quality and integrity.

In industries like pharmaceuticals and microelectronics, product integrity is paramount

Air pressure stabilisers play a critical role in maintaining the pristine conditions required within cleanroom environments.

Particle control

Cleanrooms are classified based on the maximum allowable concentration of airborne particles per cubic meter of air.

Air pressure stabilisers help uphold these strict cleanliness standards by controlling air pressure differentials and preventing the infiltration of contaminants from external areas.

This meticulous particle control is essential for ensuring the quality and reliability of products manufactured within cleanroom facilities.

Product integrity

In industries like pharmaceuticals and microelectronics, product integrity is paramount. Any deviation from the specified manufacturing conditions can lead to product defects or failures.

This meticulous particle control is essential for ensuring the quality and reliability of products manufactured within cleanroom facilities

Air pressure stabilisers help maintain consistent environmental conditions within cleanrooms, including temperature, humidity, and air pressure, thus safeguarding the integrity of sensitive products and materials throughout the manufacturing process.

Compliance with standards

Cleanroom operations are subject to rigorous regulatory standards and industry guidelines aimed at ensuring product quality, safety, and compliance.

Air pressure stabilisers are indispensable for meeting these standards by providing precise control over critical environmental parameters.

By incorporating these devices into cleanroom facilities, organisations can demonstrate their commitment to quality assurance and regulatory compliance.

To maintain the operational efficiency of an operating theatre, it is imperative to conduct annual verification

To summarise, air pressure stabilisers play a vital role in enhancing the safety, cleanliness, and efficiency of healthcare and cleanroom environments.

By maintaining precise control over air pressure differentials, these sophisticated devices contribute to infection control, air quality improvement, equipment protection, and regulatory compliance.

Whether in hospitals, laboratories, pharmaceutical facilities, or cleanrooms, air pressure stabilisers are indispensable tools for creating and sustaining controlled environments that prioritise safety, quality, and precision.

Their utilisation not only ensures the well-being of patients, staff, and visitors but also reinforces the integrity and reliability of products manufactured in controlled environments.

Top image: Aercon installation in hospital theatre, UK