The HVAC system is a vital component to deliver the level of compliance required in a controlled environment. It comes as no surprise then that air handling will undoubtedly take up a major portion of the budget within a cleanroom design and build project, not to mention on-going running costs.

Performance requirements and sustainability targets can sometimes be at odds with each other in the cleanroom world, but with a decentralised air handling system design, they can make unlikely bedfellows.

The time to embed both performance and sustainability is at the design stage of the process as that's when you have the most control. It's very difficult to achieve an optimum solution retrospectively.

Decentralised air handling?

Decentralised air handling requires no central air handling unit (AHU). Instead, it features the constituent parts of an AHU, broken down into separate pieces of plant. Fan filter units (FFUs), temperature control units and dehumidification modules are distributed locally.

Once seen as the prerequisite plant for compliance, the AHU is ever more frequently being replaced with this decentralised approach. Benefits range from reduced constructional cost and complexity to an increase in usable footprint, as a central plant room is not necessarily required. All controlled air is appropriately blended in ducting before introduction into the cleanroom through ceiling-mounted HEPA FFUs.

Zone control

Starting at facility design level, if users break down areas into smaller zones of compliance it can further reduce the level of plant-associated and control ongoing energy costs. This entails looking at each specific part of the process and defining what specification is required.

Consider a ballroom style cleanroom that encapsulates a large footprint with a single level of control - ISO Class 6 air cleanliness and tight temperature and humidity control to 18°C ±1 and 30% RH ±5. In actual fact, it may be only one part of the process that requires that level of stringent tolerances. Localising that control to a specific part of the process can reduce the cleanroom’s energy usage dramatically.

Some may argue that zones add a level of complexity to a process flow, but it reduces a lot of the ongoing energy costs. In theory, when you do it, you make compliance a lot easier as you are controlling a series of much smaller zones.

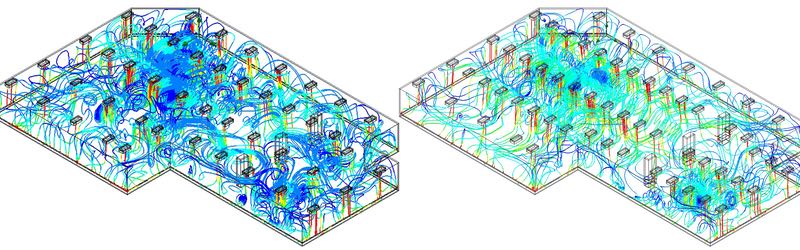

CFD Study: 45 versus 60 FFU flow trajectories

AHUs are effective at delivering single zone control - X amount of air at Y quality. However, if you ask an AHU to deliver 18°C in one room and 23°C in another, it will control to the lowest common denominator, then just before air is introduced into the other room it will need to be heated up to hit the higher temperature. With a decentralised approach to air handling, one temperature control unit can be programmed to work at 18°C in one room and another to work at 23°C in the other room. Effectively, you're only processing something once.

The last point of introduction to the controlled area is then through a HEPA FFU. In any normally ventilated environment, you need around 8-20 air changes per hour (AC/H) to deliver temperature and humidity (T&H) control. Some cleanrooms, depending on classification, will require 200+ AC/H.

The air change rate (ACR) that requires cleanliness is therefore much higher than that which is required to deliver T&H control. An AHU will have to deliver 200+ AC/H of T&H controlled air, so by zoning a cleanroom, a particular zone will need fewer air changes than if you were delivering the same air quality across a larger plant.

Resilience and modularity

An increased level of resilience and modularity is delivered with a decentralised air handling approach, where if one FFU were to fail, the others can work at an increased rate to compensate. With a zoned cleanroom, there is an increased likelihood that not every part of a facility is always in operation at any given time. This gives the freedom to operate with two validated states; an operation mode and a setback mode. That setback mode might be for reduced operation (lower occupancy) or an out of shift status, where a reduced ACR is validated along with the operational one to allow users to reduce the fan duty and save on unnecessary running costs.

With a setback mode, you still have a level of compliance and through continuous monitoring, you will have a greater understanding of the compliance data and how it tells you whether you are operating within specification.

Historically, it worked like a car MOT and a test engineer would go in annually on the day of testing and dictate if the cleanroom passed or failed through a series of tests. Then the test engineer would walk away and that user would have no idea from that day till the next test in 6-12 month's time whether they are still compliant. People then started to take periodic particle counts, say by batch, and now people are shifting more towards continuous monitoring with a remote particle sensor located next to the critical point of production and that will tell them the exact cleanliness specification throughout the entire lifecycle of that facility. A lot of industries stipulate that they need a level of audit traceability data available and with our control system, clients can record batch ID against datasets.

The values you get back from monitoring use PI control which is an algorithm that gets used a lot in control plant to modulate output from a response perspective. What it does is monitors the hysteresis curve and modulates the output depending on how it varies from the setpoint and reacting to the event. The result is a smoother hysteresis curve, meaning a more repeatable environment.

If one FFU fails, the others can compensate

For instance, when you are bringing the cleanroom back into the specification from the set-back mode, if it's needed at 9 am, it will be ready at 9 am and not 9:30. Also during operational burdens, it tracks the rate of change and reacts to it to reduce the level of variation of condition in the facility. A lot of the considerations in the planning are around where the sensors and instrumentation are located in the facility.

Computational fluid dynamics

With air handling having such a critical impact on cleanrooms' performance it's important to verify the accuracy of a proposed technical solution before it is built. Computational fluid dynamics (CFD) modelling is an effective tool to assess the impact of process, plant and equipment, as well as supply and exhaust vents on airflow models, before a cleanroom progresses from design to manufacture.

Depending on the results of a CFD study in the design phase, the amount of plant used can even be reduced. If you test the impact of say 45 versus 60 FFUs in a 1000 sqm facility, the study may identify that there are better airflows than anticipated. This reduces the initial investment and also the ongoing running costs significantly. You can also determine the airflow supply in relation to the critical areas of the facility, such as where most equipment is located. Better coverage of airflow can then be introduced across where the machines and processes exist within the room.