Cleanroom HVAC engineering is not an easy thing. It takes a mix of engineering skills, understanding the particle-generating potential of the process, and experience.

The amount of air is different in an ISO Class 6 and ISO Class 8 cleanroom. This means that the HVAC system must be capable of conditioning more than double the air. However, classification alone isn’t sufficient for calculating the airflow.

The standard ISO 14644-1:2015 does not specify the air changes per hour (ACH) for each cleanroom class because it depends on many factors.

The ACH is the number of total replacements of a room's air in one hour, and the ISO 14644-1:2015 only tells you the result that you must aim for: the maximum concentration limits for particles.

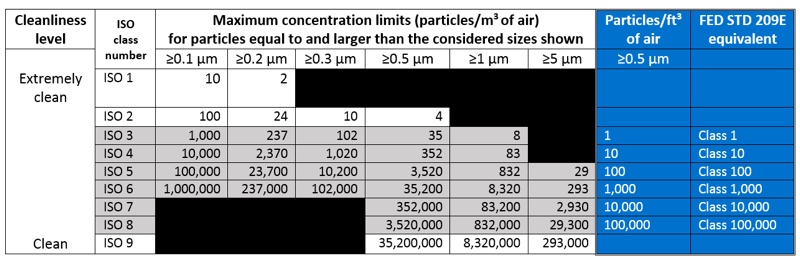

For example, for an ISO Class 7 cleanroom, particles smaller than 0.5 microns (≥0.1 µm, ≥0.2 µm, ≥0.3 µm) are not taken into consideration.

The concentration of particles of ≥0.5 µm should be below 352,000; particles of ≥1 micron should be below 83,200; and particles of ≥5 microns should be below 2,930.

ISO classification doesn’t dictate airflow

However, the ISO cleanliness level (ISO 8, 7, 6, and 5) gives a hint on the ACH range required. Notice that the term “range” is used and not “value”.