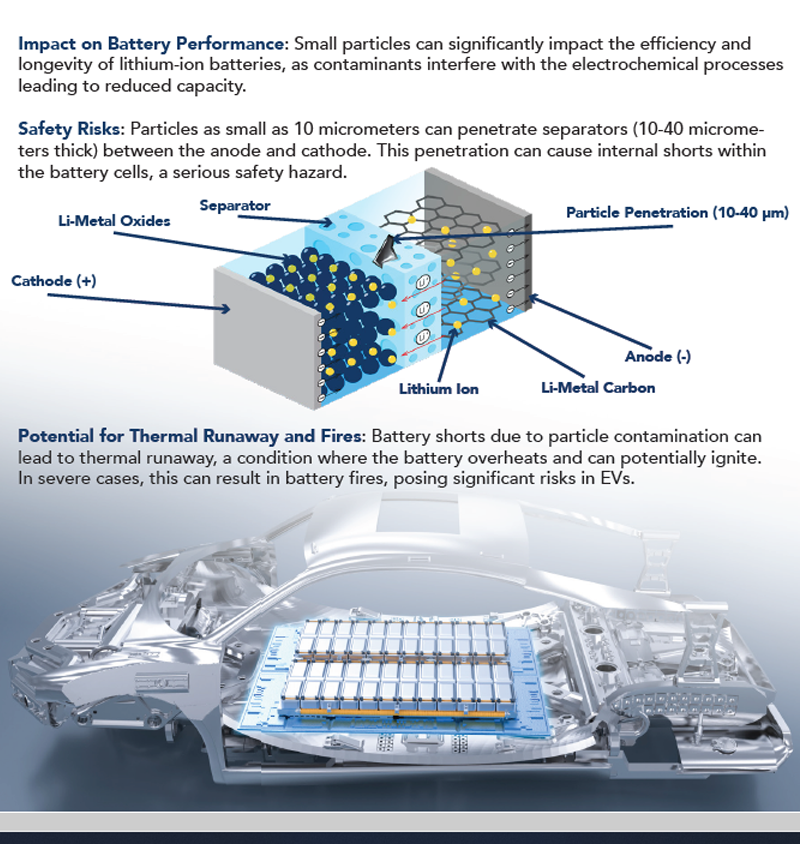

In the dynamic world of electric vehicle (EV) battery manufacturing, the quest for quality and safety is paramount. A critical yet often overlooked challenge in this quest is particle contamination. This silent adversary, akin to the challenges faced in pharmaceutical manufacturing, can significantly compromise the integrity and safety of lithium-ion batteries. Conductive particles, though minuscule, are capable of causing safety hazards such as short circuits and fires, underscoring the need for stringent contamination control.

Drawing lessons from the pharmaceutical industry, where the slightest impurity can have far-reaching consequences, the EV battery manufacturing sector has begun to adopt similar proactive approaches to contamination control. Advanced detection methods, including laser technology for large particle detection and sophisticated particle counting systems, have become integral to these industries. These technologies enable real-time monitoring and analysis, crucial for maintaining product integrity and safety.

Maintaining stringent cleanroom standards is another critical aspect of ensuring high-quality battery production. Adhering to standards such as ISO 14644, particularly achieving an ISO Class 5 cleanroom or better, is essential for minimising particle contamination. This level of control is vital for producing batteries that are not only efficient but also safe and reliable.

The introduction of the ApexRBp system marks a significant advancement in the field of EV battery manufacturing. This innovative real-time contamination monitoring system, set to start shipping on January 1st, is designed to revolutionise the industry. ApexRBp continuously monitors particle counts, providing immediate data and feedback. This capability allows for immediate corrective actions, drastically reducing the likelihood of contamination-related defects and enhancing the overall manufacturing process.

The impact of the ApexRBp system on quality and efficiency cannot be overstated. With real-time data, manufacturers can quickly identify and address sources of contamination, leading to a significant reduction in product defects and recalls. This not only ensures the production of safer, more reliable batteries but also enhances overall manufacturing efficiency. By catching potential issues early, the system helps avoid costly downtime and scrap, leading to a more streamlined and cost-effective production process.

As the demand for EVs continues to grow, the importance of reliable and safe batteries becomes increasingly crucial. The ApexRBp system represents not just a technological advancement but a commitment to a cleaner, safer future in transportation. For those in the EV battery manufacturing industry, embracing this technology could be a significant step towards achieving safer, more reliable, and efficient production processes.

With the introduction of ApexRBp, manufacturers have an opportunity to be at the forefront of innovation in cleanroom technology. As we approach its release date, the anticipation within the industry is palpable. This system is not just a tool; it's a transformative force, poised to redefine standards in EV battery manufacturing and pave the way for a more sustainable future in electric transportation. For those interested in learning more about this revolutionary system and how it can transform manufacturing processes, the time to act is now.

Be part of the change that shapes the future of EV battery manufacturing, and contact us today.