A broad spectrum of instruments and processes require thermal validation. It can be a simple temperature map of laboratory freezers all the way through to a technical aseptic fill autoclave unit.

A typical thermal validation setup would include a thermocouple-based data recorder (also known as datalogger) with an accuracy of ±0.5°C. Sensors would require pre and post-calibration, sensor placement via entry ports or door seals and a single unit validated at any one time.

Specifications for the thermocouples used would typically be Type ‘T’ Premium with single or multiple strand, encapsulated or bare end and in many different gauges. Thermocouple systems are cheap and flexible, and a damaged sensor can easily be replaced and re-calibrated.

Using wireless dataloggers for the same validation would streamline the process. Dataloggers are calibrated annually so there is no need to perform a re-calibration. They don’t need to be placed through door seals or entry glands either. So, the validation of the fridge detailed above can be arranged in minutes. With enough dataloggers, the engineer can execute multiple thermal mapping exercises at once.

Technology for thermal validation

Technology in wireless dataloggers has come a long way in the last few years. Advances in battery life, accuracy, response time, flexibility and software have all lead to an increased prevalence within the industry.

Wireless dataloggers are now available with a battery life of 10 years, accuracies from ±0.05°C, response times faster than thermocouples, with interchangeable sensors types and excellent software. Plus additional sensors are also available to measure humidity, pressure, conductivity and CO2 supporting the qualification of stability cabinets, CO2 incubators, autoclaves, and washer disinfectors.

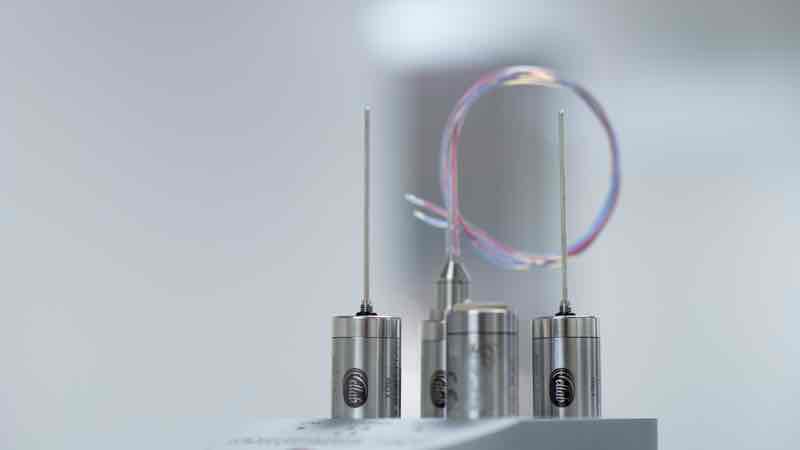

Datalogger manufacturers are looking at specific applications for sensors rather than generic sensors. Freeze drier qualification, for example, requires good sensor contact with the shelves, temperature measurements within vials, and low vacuum pressure sensors.

Specific sensors have been developed for all these unique applications, along with a plethora of accessories designed for the placement of sensors within bottles, IV bags, vials, syringes and stoppers.

Although not unique to dataloggers, new validation systems have extremely flexible software. Validation software should be compliant to 21 CFR Part 11 and be validated. Some software goes further allowing complex calculations to be performed with a clear pass and fail criteria.

An adequate setup can detail the results of all acceptance criteria along with photographs and clearly labelled sensor locations.

Setups can be used on requalification to ensure sensors are placed in the same locations for installation and operational qualification (IQOQ) and performance qualification (PQ). Performing calculations within validated software can help remove any ambiguity and objectivity from the test engineer.

Validation timeline

Thermocouples would typically require a pre and post-calibration for each project, with the risk of failure increasing when the calibration interval increases. Thermistor sensors, on the other hand, are known to have a very small drift over a year, hence calibration interval can be optimised. This feature becomes an advantage that can significantly reduce the validation timelines and remove the need to perform pre and post calibrations at the point of testing.

Thermocouples and dataloggers both have a risk of sensor damage, which if it was to occur before the calibration loop had closed would impact the qualification.

The drift of a datalogger may be minimum over one year, however, if the sensor was damaged, all of the work performed from the last verification would be unverified. To mitigate the risk of sensor damage it is recommended to perform regular calibration verifications, and ensure the integrity of the data. Calibration verification can, however, be performed offline, so the calibration downtime does not tie up the equipment under test.

Sensors are available in many shapes and sizes to suit most applications

Headquartered in Richmond (UK), Thermal Compliance has been in business since 2007 as an independent temperature mapping and validation service. The company has risk-assessed the in-house process to ensure calibration loops are optimised for accuracy, measurement uncertainty, and reduced sensor failure risk. The company has achieved this by using the manufacturers' calibration as a pre-calibration.

Calibrations are performed within an ISO 17025 accredited or traceable laboratory. This provides a superior pre-calibration with controlled measurement uncertainty and better accuracy than could be attained when performed at the point of test. The staff then perform calibration verification on the sensors on a regular basis or on a test basis dependent on clients' requirements.

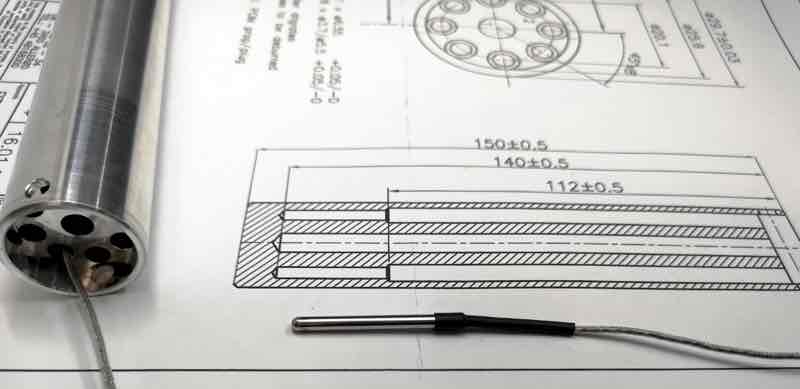

For very accurate sensors the calibration should be considered carefully. Often it’s not possible to use oil baths onsite, so at Thermal Compliance, the company has optimised dry block calibrations to ensure minimum measurement uncertainty. The staff does it by using very accurate dry baths, with inserts specifically manufactured to suit each of our sensor types.

Benefits of using wireless dataloggers

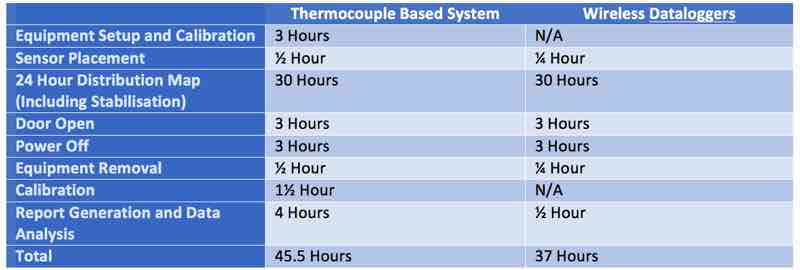

Wireless dataloggers offer a variety of benefits and not all are immediately obvious. There are time savings opportunities from a single validation when compared with thermocouple-based systems, which have been detailed in table 1 below.

Table 1: Typical time savings when performing a basic temperature mapping requalification

Time savings are compounded when you perform multiple validations together. By using dataloggers, the engineers at Thermal Compliance can perform temperature mapping on up to four units at once. These can be performed in different buildings and the workflow schedules are not significantly impacted by the additional workload.

New software is also helping to reduce thermal validation downtime. Some systems can be set up to perform calculations on the data ensuring that the results in the report correspond to the acceptance criteria in the protocol.

In the case of autoclaves, for example, equilibration time, fluctuation and difference can all be calculated with a clear pass and fail criteria detailed within the report.

The calculations are performed with validated software with minimal data analysis and review time. By performing calculations within the software, they are made in a repeatable manner, hence the potential for subjectivity by the validation engineer is removed.

Best practice

Companies interested in using wireless dataloggers should take a closer look at the user requirement specification (URS) to ensure it is suitable for the application.

There are a vast array of thermal validation dataloggers available on the market, and it is important to ensure that the sensors you choose meet your requirements. The list below details some of the parameters you should consider in your URS:

- Accuracy: minimum of ±0.5°C

- Response time: Ꚍ90 ≤5 seconds for sensors used in autoclave validation

- Battery life: as long as possible

- Temperature range: consider your requirements freezers, autoclaves, etc.

- Equipment use: autoclaves, steam-in-place, depyrogentation, ultra-low freezers

- Parameters: do you need to map RH, CO2, conductivity or pressure

- ATEX: do you need to use the sensor in ATEX Environments

- Software: 21 CFR Part 11 compliant

- Data integrity: can the software be validated?

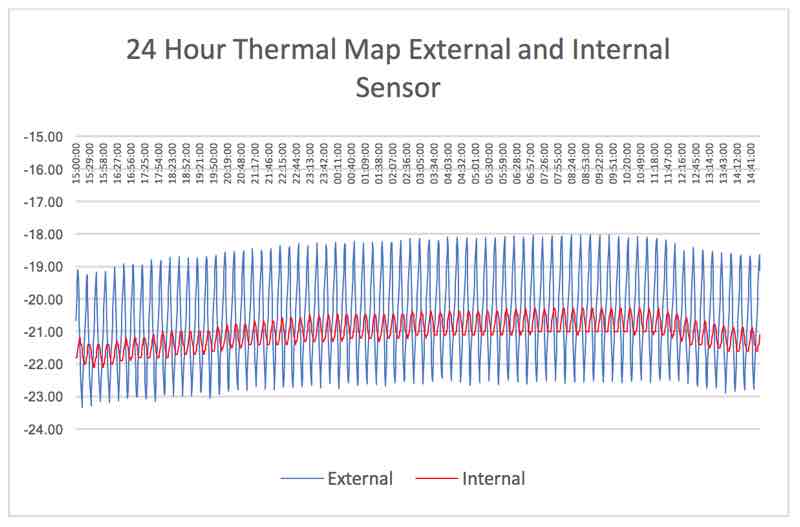

Response time is the time taken to register a change in temperature. For sensors with thicker probes or internal sensors, the response time will be greater due to the insulation of the thicker material or air. High response times refers to cases where the temperature is not stable leading to extremities (high and low) not recorded.

It is worth ensuring that any new equipment you buy is flexible enough to be used with all of your onsite processes

It’s also important to consider the equipment required for thermal mapping. For example, do you need to place penetration sensors in bottles? It might seem obvious, but if you need to place sensors in a five-litre cryo bag, you need to ensure the sensor is long enough and flexible enough to reach the desired location.

As mentioned earlier, sensors are available in many shapes and sizes to suit most applications. It is worth ensuring that any new equipment you buy is flexible enough to be used with all of your onsite processes, both in terms of sensor positioning and temperature range.

The graph below shows a 24-hour thermal map of a -20°C freezer. There are two sensors—external and internal—placed side by side in a freezer. The external sensor records the extremities of the data with fluctuation of 5.32°C. As the internal sensor is buffered by air, it takes longer for the fluctuations in temperature to be recorded by the thermistor probe. The internal sensor has a fluctuation of 1.80°C.

A 24-hour thermal map of a -20°C freezer

Battery life is an important consideration when moving to dataloggers. Most dataloggers have long-life batteries, with some lasting up to 10 years. A good battery management policy will help to ensure that there is no data loss.

It is also worth considering the use of cycling batteries between hot and cold environments as it will shorten the batteries life. The battery life will also be impacted by the log intervals: the longer the interval the longer the battery life.

Consider your temperature range carefully. Do you need to map ultra-low temperature freezers? Will the sensors be used in autoclaves, ovens, and incubators? The greater the temperature range the higher the datalogger cost, so if you only need to map 2-8°C refrigerators and incubators you don’t require a high-specification autoclave datalogger. You may, however, need to consider whether you would need additional parameters like humidity or CO2. Some manufacturers allow you to overlay different parameters over the same graph, which can be very useful.

Another key element to factor is the software. Often overlooked, the software should be a critical parameter. The best validation software can reduce execution, data analysis, report generation, programming and review timelines.

Careful consideration is required for your specific applications. Although software can significantly reduce validation timelines on complex projects it does require experience and knowledge. If for example, you are validating a refrigerator that requires simple acceptance criteria, you would not need advanced software.

Traditional thermocouple-based systems offer affordable flexibility albeit with longer execution, data analysis and reviewing times. Wireless dataloggers provide validation departments with the opportunity to reduce thermal validation timelines.

Currently, thermocouples provide the best method of thermal validation for some environments like liquid nitrogen or dry heat ovens. Dataloggers work well within their specified temperature ranges and offer some useful time-saving benefits.

As datalogging and sensor technology continue to improve we can expect wireless dataloggers to become more prevalent within the industry.

N.B. This article is featured in the August 2019 issue of Cleanroom Technology. The latest digital edition is available online.