The Hohenstein Institut für Textilinnovation recently joined forces with Labor Dr. Merk & Kollegen to focus on the issue of hand disinfection on a project under the ZIM programme (Central Innovation Programme for SMEs). The aim of this project was to develop a new model for testing hand disinfectants under realistic conditions of use.

By simulating the rubbing process adopted with hand disinfectants, the new hand hygiene model makes it possible to obtain results which correlate with data from tests performed on human subjects..

New disinfectants can now be screened under realistic conditions, so saving costs and eliminating potential risk to test subjects. With the model it is also possible to perform comparative studies for different formulations of a disinfectant using a method that is fast and does not waste resources. .

It not only allows the bactericidal effect to be established, but above all the efficacy of disinfectants against viruses through practical testing. These tests involve the use of a synthetic skin whose properties correspond to those of human skin in terms of pH value, topography, fat content and moisture management. The scientists at Hohenstein have also optimised the synthetic skin so that it can be used as a substitute for the hands of human test subjects.

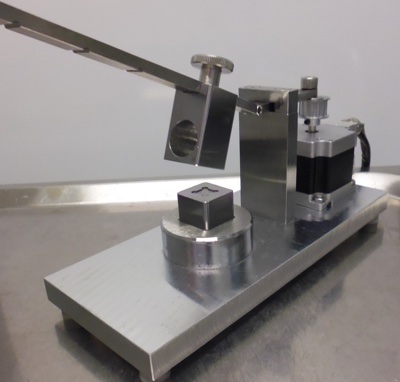

The new test device makes it possible to simulate hand rubbing action in a realistic manner. Picture courtesy of Labor Dr. Merck & Kollegen

A further result of the project is the development of a motorised simulator equipped with a pivoting arm. The synthetic skin can be secured at the point of contact between the arm and base. Rotation of the arm over the surface and the selected pressure setting successfully simulates a rubbing action that resembles the motion of hand rubbing during disinfection.

The scientists at Labor Dr. Merk & Kollegen performed virological tests using both the new model and human subjects and acquired data on the effectiveness of a number of commercially available disinfectants against noro, vaccinia and adeno viruses. The results of the tests performed on human subjects correlated with those for testing with the hand disinfection model.

In the course of the project scientists from both companies were also able to simulate and evaluate practical transmission scenarios. Chains of infection (e.g hand - door handle - hand) were reproduced with a stamp model using the synthetic skin or various metal plates. This was followed by analysis of the results. This demonstrated how important thorough hand disinfection is to interrupt the simulated chain of infection.

It is of great importance for medical facilities to prevent nosocomial infections, i.e. those acquired at hospitals or care homes, and specifically to avoid viral diseases. Viral diseases are often extremely contagious and spread like wildfire among patients. Disinfection of the hands, above all by staff and visitors, is an effective means of interrupting the chain of infection, so reducing the transmission of viruses. It is critical here to find the appropriate hand disinfectant.

The VAH association (Association for Applied Hygiene) or the Robert-Koch Institute list those disinfectants categorised as being effective against viruses and authorised for use by medical facilities. To obtain such a listing for a hand disinfectant, the manufacturer must submit expert reports documenting its effectiveness, whereby this needs to have been ascertained by means of quantitative suspension testing. However, these tests are not designed to map the disinfecting effect in practical application.

The tests performed to date on human subjects are in contrast costly and always entail a risk of infection for the test person. They are, however, essential to assess actual disinfecting performance. With this background the new hand disinfection model represents a realistic test method that does not require the involvement of human subjects to establish the effectiveness of hand disinfectants under realistic conditions.