As a method for vibration isolation, the traditional air table is now being challenged by the more compact and effective Negative-Stiffness vibration isolators, developed by Minus K Technology.

For almost 40 years pneumatic vibration isolators – air tables – have been the mainstay for stabilising industry and academia’s most critical micro-engineering instrumentation. But just as technology has been migrating steadily from micro to nano, so has the need for more precise vibration isolation in micro-electronics fabrication, industrial laser/optical systems and biological research.

These so-called “passive system” air tables are now being seriously challenged by the newer Negative-Stiffness vibration isolators. Negative-Stiffness isolation is rapidly gaining popularity in industrial and laboratory environments, mainly because of its ability to isolate vibration effectively in diverse and challenging environments.

Air tables are now being seriously challenged by the newer Negative-Stiffness vibration isolators

Negative-Stiffness mechanism vibration isolation systems were invented by Dr David Platus, who worked in the nuclear, aerospace and defence industries conducting and directing analysis and design projects in structural-mechanical systems; he holds more than 20 patents related to shock and vibration isolation.

In 1993 Platus founded Minus K Technology to develop, manufacture and market vibration isolation products based on the company’s patented technology. The resulting products, sold under the trade name Nano-K, are used in a broad spectrum of applications, including nanotechnology, biological sciences, semiconductors, materials research, zero-g simulation of spacecraft and high-end audio.

Air tables can typically handle vibrations down to only about 8 to 10Hz, not quite low enough for optimum performance with modern nano-equipment

Basically cans of air, air tables have been used for isolation purposes since the 1960s and are still the most popular isolators used. But air tables with resonant frequencies at 2 to 2.5Hz can typically handle vibrations down to only about 8 to 10Hz, not quite low enough for optimum performance with modern nano-equipment. Also, greater isolation efficiencies are needed in the frequency ranges air isolators can handle.

Because of their very high isolation efficiencies, Negative-Stiffness vibration isolation systems enable vibration-sensitive instruments, such as scanning probe microscopes, micro-hardness testers, profilers and scanning electron microscopes, to operate in harsh conditions and severe vibration environments that would not be practical with top-performance air tables and other pneumatic isolation systems.

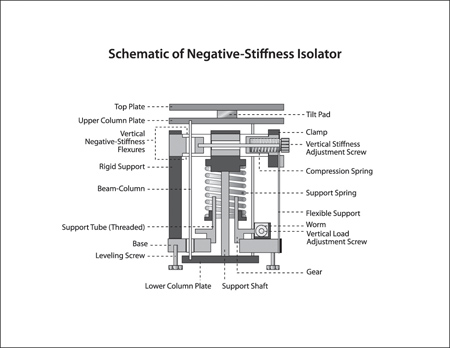

Negative-Stiffness isolators employ a different and completely mechanical concept in low-frequency vibration isolation. Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism. The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring.

Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. The horizontal stiffness of the beam-columns is reduced by the “beam-column” effect. (A beam-column behaves as a spring combined with a Negative-Stiffness mechanism.)

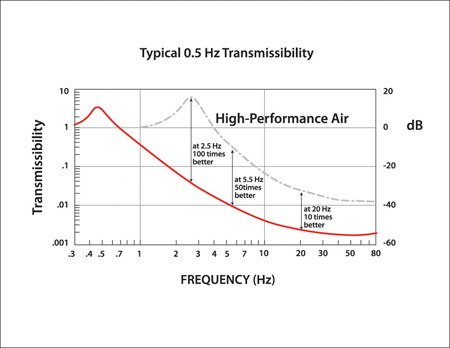

The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and very high internal structural frequencies. The isolators (adjusted to 0.5Hz) achieve 93% isolation efficiency at 2Hz; 99% at 5Hz; and 99.7% at 10Hz.

Schematic of Negative-Stiffness isolator

The following key points demonstrate the benefits of Negative-Stiffness isolators compared with air isolation systems:

Low Hertz perturbations: An air table will amplify vibrations in a typical range of 2–7Hz; this is because of the natural frequencies at which air tables resonate. All isolators will amplify at their resonant frequency, and then they will start isolating. So with an air table, any vibration in that range could not only fail to be mitigated, it could be amplified. The low cycle perturbations would just come straight through to the instrument.

Negative-Stiffness isolators resonate at 0.5Hz. At this frequency there is almost no energy present. It would be very unusual to find a significant vibration at 0.5Hz.

Image clarity: Negative-Stiffness vibration isolation can reduce vibration noise levels in Atomic Force Microscopes, for example, by a factor of 2 to 3 when compared with top-performance air tables. This is significant for noise levels in the sub-Angstrom range. This results in clearer images and features not discernible with pneumatic isolation systems.

Severe vibration environments: As nano-equipment becomes more prevalent, lab sites are being set up in much more severe vibration-prone environments, such as upper floors of buildings and cleanrooms. Such severe vibration locations are too extreme for pneumatic isolators to do their job effectively. But Negative-Stiffness isolators perform well in such environments, producing much better images and data than can be obtained with even the best high-performance air tables.

Harsh environments: Air tables are not particularly compatible with operations in vacuums, extreme high and low temperatures, and radiation. Yet these harsh environments are often necessary when conducting research or testing, such as with cryogenic chambers in semiconductor research.

All metal Negative-Stiffness systems can be configured to be compatible with high vacuums and other adverse environments, such as extreme high and low temperatures, and radiation. With vacuums, for example, Negative-Stiffness isolators can be used right inside the vacuum chambers. This offers other advantages, such as much lower payload weights and more compact systems, and eliminates problems associated with vacuum chamber feed-through.

Compressed air: Air tables require a constant supply of compressed air, via either a dedicated compressed air line plumbed into the lab, a tank of pressurised gas or a small compressor. Even with a dedicated compressed air line, the table’s location is still limited by the length of the air line.

Furthermore, large tanks of compressed gas have to be mounted very securely to minimise their danger. Changing the tanks can be quite difficult and inconvenient as well. Compressors are sources of both mechanical and acoustic noise and are very poor choices from a vibration standpoint.

It is advantageous to isolate the nano-environment mechanically without recourse to compressed air. Negative-Stiffness isolators do not require compressed air and operate purely in a mechanical mode.

Negative-Stiffness isolators are available in high-performance benchtop configurations

Location selection: Air tables are big, bulky structures that take up a lot of lab space. The high-performance air tables are even bigger. This can be a limiting factor when laying out equipment in the lab. Negative-Stiffness isolators are available in high-performance benchtop configurations, considerably more compact than air tables and easy to move around.

They are also available as workstations, tables and floor platforms where these configurations are required.

Load adjustment: Low-frequency passive vibration isolators are somewhat sensitive to small changes in weight loads, as well as to large displacements. Pneumatic systems utilise levelling valves to mitigate the problem.

Negative-Stiffness isolators provide a very simple manual adjustment to accommodate variations in weight loads. For applications where manual load adjustment is not practical they provide an auto-adjust system that maintains the isolator in a precise vertical equilibrium position.

Scanning probe microscopes: Scanning probe microscopes (SPMs) have vibration isolation requirements that are unparalleled in the metrology world. The vertical axis is the most sensitive for most SPMs. They can also be quite sensitive to vibrations in the horizontal axes. To achieve the lowest possible noise floor, i.e. on the order of an Angstrom, isolation is always used.

Benchtop air systems provide limited isolation vertically and very little isolation horizontally. Negative-Stiffness isolators provide increased isolation performance for SPMs over air tables, while offering better ease-of-use and no facility requirements. Negative-Stiffness isolators have the flexibility of custom tailoring resonant frequencies vertically and horizontally.

Transmissibility - Negative Stiffness isolators vs air tables

Laser and optical equipment: Laser and optical systems, whether used in an academic lab or in an industrial environment, are very susceptible to vibrations from the environment. These instruments almost always need vibration isolation. Traditionally, large air tables have been the isolators preferred for optical systems, but Negative-Stiffness isolators are becoming a popular choice because they provide 10 to 100 times the performance (depending on vibration frequency).

Laser-based interferometers are extremely sensitive devices capable of resolving nanometre-scale motions and features. They often have very long mechanical paths, which makes them even more sensitive to vibrations. The sophisticated modern ellipsometry techniques that allow this high performance rely on low noise to be able to detect fringe movement. Properly isolating an interferometer will allow it to provide the highest possible resolution.

Optical profilers have similar sensitivity to vibrations. Optical component systems are often quite complex. The long optical paths can lead to angular magnification of vibrations. Optical air tables can make the problems worse since they have a resonant frequency that often matches that of floor vibrations. Negative-Stiffness 0.5Hz isolators provide isolation in these environments when air tables simply cannot.

Maintenance and expense: Because Negative-Stiffness isolators utilise simple elastic structures and viscoelastic materials that deform, their isolation performance does not degrade with micromotions typical of lab floors and fabrication rooms, as do conventional pneumatic isolators. Negative-Stiffness isolators are also comparable in price to air isolators or lower priced for many applications.

As industrial researchers and universities continue to broaden their nanotech work, necessitating more sensitive equipment and expanded lab facilities, vibration-handicapped environments will become more prevalent, and a better vibration isolation solution will be required than that provided by air tables for the past half-century. It appears Negative-Stiffness vibration isolation will fill that void.