The food sector is in some way related to the pharmaceutical sector, in that they both produce products that are for human consumption in clean, hygienic conditions, however, one sector (pharmaceuticals) is more regulated than the other.

The food sector has come a long way from mercury thermometers and it has taken it a while to embrace technology and enforce guidelines with regards to temperature records and 24/7 monitoring, to prove that food and ingredients are kept at the correct temperature and that the chill chain has not been broken.

However, what about contamination during production? In pharmaceutical manufacturing, contamination is extensively controlled and monitored in line with strict guidelines and regulations. However, in the food sector the guidelines are based around HACCP (Hazard Analysis and Critical Control Points).

This is a systematic preventive approach to food safety from biological, chemical and physical hazards in production processes that can cause the finished product to be unsafe. The procedures that are implemented are designed to reduce these risks in order to make the process safe.

The Food Standards Agency has developed a range of food safety management packs for different sectors of the food industry to help food business operators implement food safety management procedures as part of their manufacturing processes. In the meat processing industry, it is stated that it is important to minimise the likelihood of food poisoning bacteria contaminating meat and associated products from microbiological, chemical or physical hazards.

This requires Good Hygiene Practices, including: Maintenance, cleaning, pest control, training, personal hygiene, traceability, waste management, wrapping and packaging, as well as finding a practical way of maintaining these control measures during the transport phase of the product life cycle. However, there is no mention of contamination from airborne particles (bioaerosols).

Airborne contamination

Bioaerosols are solid or liquid microscopic particles suspended in air (aerosols) that carry microbes1, hence the term bioaerosols.

A bioaerosol may be created from:

- Foot- and wheeled-traffic (e.g. forklifts, handcarts) passing through standing water in which microorganisms have grown

- Application of high-pressure washers to contaminated surfaces

- Use of compressed air lines that do not have appropriate point-of-use filters in which condensate has accumulated; and

- Various unhygienic designs of air handling units (AHUs).

Validair provides a modern approach to monitoring and critical alarm notification for controlled environment and process applications, including those in the food industry

Bioaerosols will be suspended in the air for various lengths of time. The settle rate is rougly dependent upon the size of the airborne particle.

Bioaerosols of vegetative (nonspore) cells liberated into an open space will become diluted and deformed as they mix with the air in the environment. The bioaerosols will move from high to low pressure on air currents in the plant. This highlights the importance of appropriately filtered air in rooms with elevated hygienic controls, such as filling and packaging rooms, compared with with less controlled areas of the plant where non-critical elements of the process are carried out.

Measuring particles

Other contamination sources that might affect the processing environment exist. These may include soiled work clothes, street shoes, roof leaks, inadequately trapped floor drains, drain backups and negative air pressure in the plant drawing in air from contaminated outside areas.

Food industry market information would indicate that the principle concern related to airborn contamination is focused on particles between 5 and 20 microns. Particles larger than 20 microns are likely to settle quickly and can be removed by adequate cleaning and sanitisation techniques applied to the plant environment.2 This does, however, provoke questions regarding measurement of particles in terms of the volume and size, which would determine how the particles are controlled within a food manufacturing environment.

The requirement for contamination control is more relevant to the food manufacturing process, as opposed to food service and food retail sectors, as the raw ingredients need protecting from viable and non-viable contaminants.

The implementation of an airborne particle monitoring system could form part of a company’s HACCP procedures extending their approach to food safety to include contamination control. This could be achieved with the use of handheld, or portable devices to identify areas of concern.

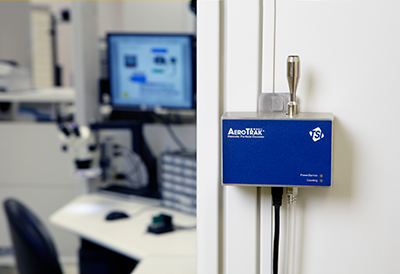

AeroTrak® Portable Particle Counter is suitable for Particle contamination monitoring

Some forward-thinking food processing companies implement technology to secure and maintain contracts with, for example, supermarkets. In so doing, these companies are demonstrating that their food safety standards and levels of hygiene control exceed the current food industry requirements and that these control measures are robust in terms of future proofing their process and operational procedures.

The sector is a long way off ISO14644-1 (2015); exactly how a food processing plant would be classified without the standards in place to regulate it, could take time to be resolved. However, the drive to introduce new methods, and guidelines sometimes comes from the industry itself, and not the regulators.

References

- J.L. Kornacki and J.B. Gurtler. 2007. Incidence and control of Listeria in food processing facilities. In Ryser, E.T. and E.H. Marth (eds.), Listeria, listeriosis, and food safety, 3rd edn., Boca Raton, FL: CRC Press, pp.681–766

- J L. Kornacki, Airborne Contamination: A Microbiologists Perspective. Food Safety Magazine, June/July 2014 published on-line http://www.foodsafetymagazine.com/magazine-archive1/junejuly-2014/airborne-contamination-a-microbiologiste28099s-perspective/