"The business is developing and so is my team," Joe Govier, founder and CEO of Connect 2 Cleanrooms (C2C), tells me and I read in his statement the mindset running the business. Last July, and only two weeks after announcing the completion of a bespoke telescopic cleanroom for a CERN facility in France, the UK company made headlines with a management overhaul. Head of Operations Michael Wright was promoted to Managing Director as Govier took on the CEO role. The move, Govier explains, is not a revamp of the business, but an evolution. "Our plan is to stay at the front, pushing the boundaries and listening to our customers to improve the supply chain and overall value proposition," he says.

The management leadership update coincides with a fruitful period at C2C. The specialist in all things critical production environment has reported business performance at 29% CAGR, and that it's on track for a £20 million turnover by 2020. "Pharmaceuticals and different treatment therapies are bringing growth for GMP environments, and the UK is still fundamental to these markets, sitting at the core of a lot of this innovation," Govier says.

Govier founded C2C in 2002, and has been running it ever since. An award-winning company, C2C is known for accomplishing high-calibre contracts for clients the like of ConvaTec, the British medical devices maker, and Parker Bioscience. C2C took home the Cleanroom Technology Conference Award 2018, and was highly commended in 2019 for these projects, respectively. Govier knows the cleanroom business inside out, and that know-how is now supporting the internationalisation of the company even further.

"Pharmaceuticals and different treatment therapies are bringing growth for GMP environments, and the UK is still fundamental to these markets

Govier's business venture started with Details Plastics, a company focused on developing single-use devices and products for the medical and life science markets. The business required a cleanroom, and so Govier's connection with the industry began. "My first cleanrooms were Class K featuring soft walls that could easily adapt to different shapes," he tells me.

At the time, the ruling standard was the BS5295, commonly cross-referenced to the US Federal 209e, but not so much the ISO 14644 we know today. "The primary focus was about performance and compliance and no about the appearance. No standard said the walls must be white," he says.

C2C is known for accomplishing high-calibre contracts for clients the like of British medical devices maker ConvaTec and Parker Bioscience, as shown in this photo

Today the Lancashire-based company employs 84 people globally, but the majority is based in the UK where design, manufacture, marketing, finance and HR departments are located. But don't let the British location fool you. Govier tells me the company's footprint is fluid: "We work on a global basis with up to 40% of our business coming from outside of the UK," he says. The C2C chief recognises the company has a strong commitment to customers in mainland Europe, which led to establishing a subsidiary in Utrecht, the Netherlands, in 2018. "We also have a small group of trusted distribution partners who can support our clients in other regions."

Business acumen

The man at the helm of C2C is a former 10 Downing Street advisor. Govier worked with various government departments on many SME business growth initiatives including the New Deal, the workfare programme introduced in the UK in 1998. Govier would sit in meetings with the head of the Bank of England, Ministers and many others representing the viewpoint of small business owners and entrepreneurs. "The highlights were meeting many other high-profile entrepreneurs such as Richard Branson, Alan Sugar and many more," he recalls.

In C2C's co-pilot seat is an engineer and aerospace connoisseur recruited in 2015. Govier tells me the appointment of Wright was rooted in the notion that bringing people in from outside of the cleanroom industry allows the company "to learn and look for inspiration from other markets".

Wright joined C2C after 15 years in the aerospace and defence industry, having worked at BAE Systems and Angus Fire. At C2C, he has had the insider view of the segment that today is keeping manufacturers and service providers in the cleanroom market busy—perhaps more than ever before.

We need to be able to present the right sector language and alignment while still being flexible enough to fulfil the individual needs of a range of market sectors

"I have had various involvements with cleanrooms throughout my career, primarily through manufacturing processes in the defence and aerospace industry," Wright says. "I think the cleanroom market is a fascinating and exciting place but provides certain challenges to solutions providers like C2C," he adds. Wright notes that the customer base of C2C is very varied in the structure and support they require. "We need to be able to present the right sector language and alignment while still being flexible enough to fulfil the individual needs of a range of market sectors and maintaining our own unique identity," he says. Wright believes his background is a bonus for the C2C offering.

Global reach

Further internationalisation is C2C's next goal on the horizon. Govier tells me his first international contract was sixteen years ago with a project in the Canary Islands that saw C2C build a mobile soft cleanroom for assembling and servicing of a telescope that was going to the largest solar observatory based on Mount Teide. Several other projects across Europe have followed ever since. "We have explored opportunities in Asia and the Americas, so watch this space," Govier says, yet points out the UK has many advantages for doing business. "The more you look at other global markets you realise what a great business environment the UK is: our laws, regulation, funding and innovation are number one," he says.

Consumables are yet another buoyant market for C2C. Launched in 2003, the e-commerce Cleanroomshop.com offers a single-supply solution for cleanroom users based on a portfolio of 250 products. With a warehouse in the UK, the company ships worldwide—a fan filter unit was delivered to the Antarctic earlier this year.

The more you look at other global markets you realise what a great business environment the UK is

"No two customers are the same, but the challenges they face are shared," Govier says, responding to my question about the customer profile. "What they want is what is written in their process, and therefore, the discovery of new products can be scary and risky," he says. For Govier, the C2C team helps to build confidence with clients to test new approaches. "We see lots of new products such as biodegradable materials and disinfectants, and plastic-free packaging solutions. The challenge is that change takes time in this market, so I'm always looking for partners who are willing to make long term and realistic forecasts," he explains.

Change is slow, but Govier knows it's equally, necessary. "Some of our regulation comes from within, but some comes from outside and can be enforced quickly. The recent short enforcement date for EU BPR 1062/2014 within our world has caught a lot of businesses out. It's a learning opportunity, and I would like to see us work more collaboratively to share ideas and innovation across our industry," he points out.

A new era

Wright also recognises the changes within the company have paved the way to current successes. "We're innovators focused on customer-centred solutions. Our flexibility, agility and adaptability are a key strength. This internal energy to develop is perceived by our clients when they meet the team," he says, adding the adoption of technology is a factor moving the company forward. "We recognise that our customers—be it through cleanroom construction, consumables supply or validations—rely heavily on us in fulfilling their needs. We are the enablers to our customer's success, and leave no elements of the design and specification process to chance," he says.

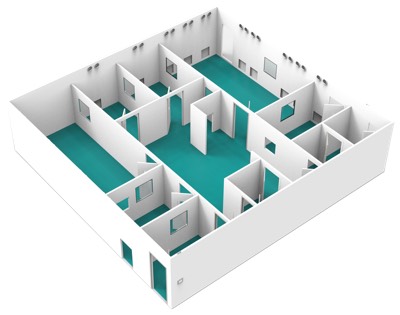

3D models of customer's existing facilities with the new facility embedded helps them see

the digital representation of a project

At C2C, Wright tells me, the team assumes the role of industry leaders in offsite construction, which makes the company stand out. He explains: "Our comprehensive digital site surveys, coupled with utilising material requirements planning (MRP) systems ensure that we minimise the amount of construction and material conversion processes that take place on a client's site. This minimises disruption and enables us to configure cleanrooms from a library of known components and controlled interfaces. The absolute commitment to this approach throughout the organisation means that we can have a huge degree of confidence in having the right components in the right place at the right time, delivering an optimised speed of installation with minimum waste and disruption."

The conversation inevitably leads to questions about modular and prefabrication, and Wright points to business opportunities in the next generation of modularity.

"Modularity enables the manufacturer to minimise the variation in their product and turn to economies of scale, passing the price benefit to the customer with minimal compromise to their project," he says. "This is an area where C2C leads the way. The natural evolution of the offsite construction approach is to find new and more innovative ways of passing these benefits to our clients," he adds.

Wright then strikes me with an epiphany. Inspired on Steven Covey's "7 habits of highly effective people", he tells me that one of those habits is "begin with the end in mind", and this approach is key for planning a cleanroom facility. "You have to clearly understand how you will measure its success once the facility is completed. Too few clients focus on this, preferring to look at the physical construction of the cleanroom," he says, pointing out that the same principles apply in ISO 14464:2015-4, as those outlined in GMP guidance. "This approach has to be a collaborative process and not wholly-owned by either client or solutions provider," he says.

Govier and Wright are business leaders and complement each other well. "Joe is a real futurist, always looking forward to the next opportunity," Wright tells me, adding: "I want myself and my team always to be moving forward." Govier concurs: "The business day never really finishes, and it all just merges to one big adventure."