Let’s start with what Para 7 of Annex-1 has to say about the personnel and garment qualification and also its relevance to the article:

Para 7.13 and 7.15 specifically talks about garments and its specification to be compliant with the cleanroom use. For example, in 7.15- “Every operator entering grade B or A areas should gown into clean, sterilised protective garments (including eye coverings and masks) of an appropriate size at each entry. The maximum period for which the sterilised gown may be worn before replacement during a shift should be defined as part of the garment qualification.”

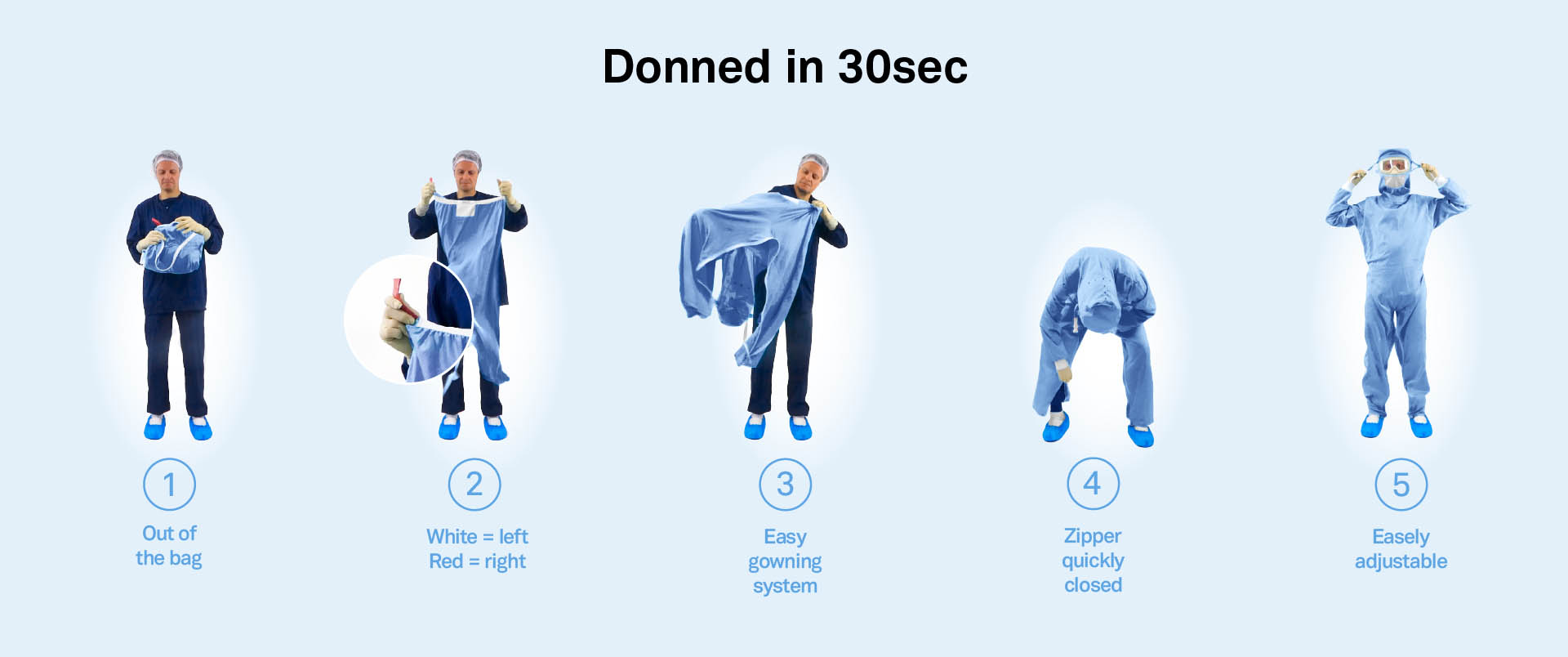

Further, para 7.13 describes the gowning requirements as per each grade of cleanroom. It says the operator in Grades A and B must wear undergarments under their sterile suits before entering the cleanroom. It highlights the use of sterile headgear to cover all hair (incl. facial hair) and a sterile facemask together with sterile eye coverings (e.g. goggles) to cover all facial skin and prevent the shedding of droplets and particles. Lastly, there’s something unique about the garment folding process also so that the operator can don the gown without contacting the outer surface of the garment and touching the floor.

So, in the light of Para 7, we are going to talk about one of the most popular and accepted innovations that has happened in the recent past. A coverall with integrated goggles.

Requirements for garments can differ vastly depending on the classification of the cleanroom. The higher the class and grade of cleanroom, the more protection is required for keeping the environment safe from any type of contamination. That is where the coverall with integrated goggles is very important which does not allow any part of the skin to be exposed to free air. The all-in-one gowning system guarantees better contamination control and a significant reduction in discarded plastic waste. The goggles are designed with the key priority of safeguarding the comfort of the operator via separate respiratory and visual compartments to prevent fogging. They are light and durable with superior peripheral visibility and are suitable for wearers of prescription glasses.

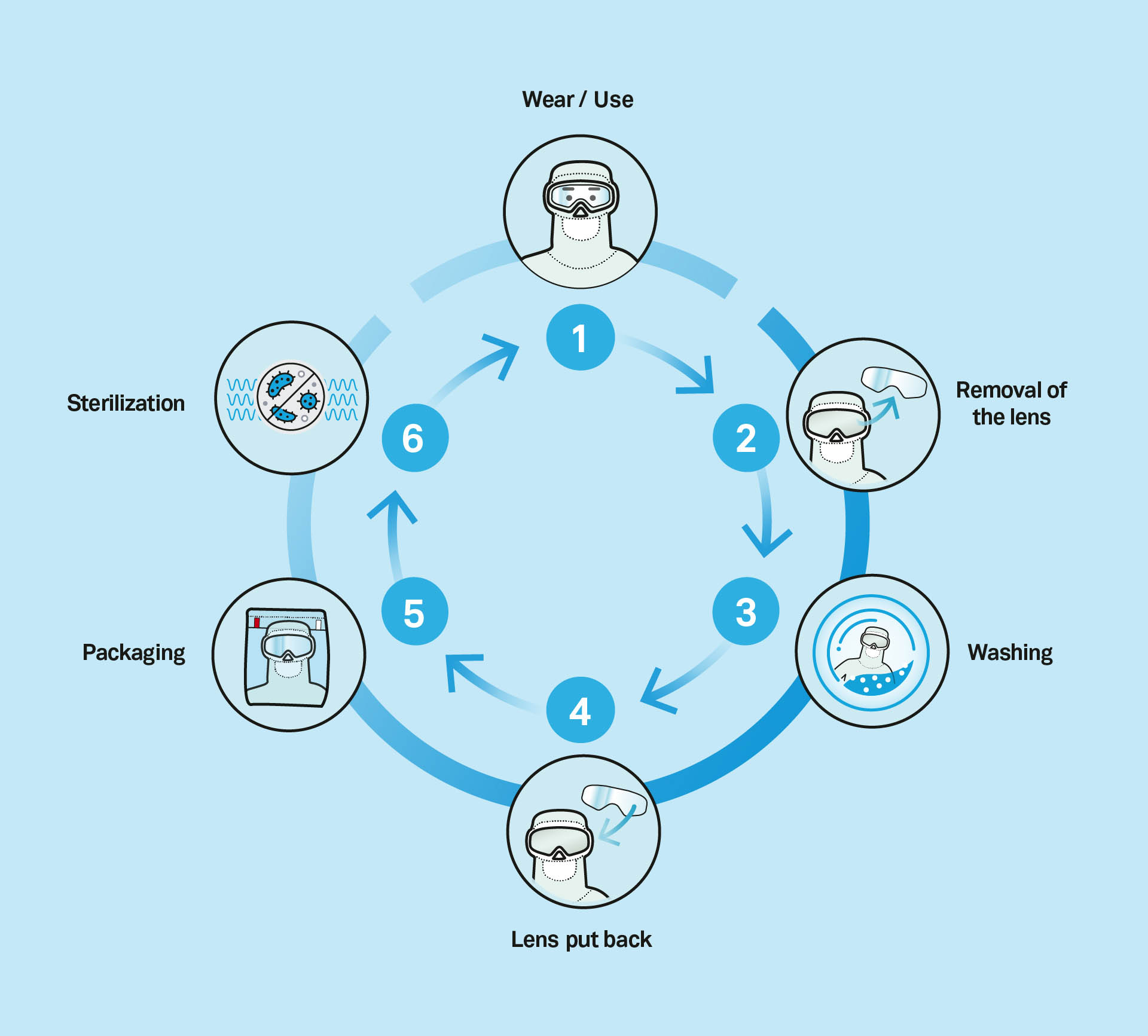

Particular attention has been given to the choice of materials: they are soft and resistant to multiple washing and/or sterilisation cycles. They are available in two sterilization versions: gamma and autoclave (steam).

Features

- A hood that fits perfectly and completely encloses the head, providing full protection with excellent comfort.

- Gowning without touching the coverall: The design is unique in the fact that the outside of the garment is protected from any risk of contact contamination (hand and surface).

- No separate goggles and easy visor/lens changes

Advantages

Annex-1: The innovation has been made keeping in mind the new GMP Annex-1 which forbids any part of the skin to be exposed in Class 5, Class 4 and lower cleanroom environments.

- Reusability: The garment is highly reusable with longer product life than average coveralls and can support multiple types of sterilisation

- Applications: The garment has been primarily designed for the life science industry but its use can be extended to any other industry and sector employing cleanrooms like Biotechnology, electronics, medical device manufacturing etc

The specs on paper

High-quality cleanroom fabric:

- Twill 3/2 – grid 5 mm x 5 mm - pore size 10-18 μm

- Anti-static yarn

- Filtration efficiency > 95% 0.5 μm

- High-quality cleanroom finishing (double seam – accessories available)

- A perfectly smooth technical filtering wall, at both front and back, constitutes a veritable barrier against human contamination

- Perfectly closed integrated goggles in compliance with the new GMP Annex-1

- High comfort for the wearer

- Non-direct ventilation holes which prevent fogging of the visor (alternative with no ventilation also available)

Sterilisation details

- Specific TPU material for the goggle with high performance for gamma sterilisation

- Specific TPV material for the goggle with high performance for autoclaving

- Both TPU and TPV can be used for ETO sterilisation

Garment withstands several sterilisation cycles, not depending on whether if gamma, ETO or steam sterilisation is applied.