Understanding how stem cells transform into the wide range of specialised cells that make up the human body could eventually help in preventing some of the most serious medical conditions. Another area for stem cell research is in the manufacture of cells and tissue for medical therapies. This could replace the use of donated organs and tissue to replace those that are diseased or destroyed. The number of people needing a transplant far exceeds the number of organs available for transplantation. So-called pluripotent stem cells offer the possibility of a renewable source of replacement cells and tissue to treat a myriad of diseases, conditions and disabilities, including Parkinson’s disease, amyotrophic lateral sclerosis, spinal cord injury, burns, heart disease, diabetes and arthritis.

Bioscience Institute, a company specialising in this field with an established business in San Marino, Italy offering advanced therapeutic techniques, has decided to branch out into the Middle East. In San Marino, Bioscience Institute has a cell factory dedicated to biological cryopreservation, cellular culture and scientific research. Extraction, analysis, expansion and programmed freezing of different cell types are carried out in its laboratories.

The company has chosen the GCC (Gulf Co-operation Council) area as a launch pad into the Middle East, initially offering a range of aesthetic and anti-ageing treatments. These treatments are based on the extraction, expansion and cryopreservation of autologous fibroblasts isolated from a small skin biopsy.

The GCC member states include the United Arab Emirates, Bahrain, Saudi Arabia, Oman, Qatar and Kuwait, with a total population of approximately 42 million according to surveys in 2012. Population in the GCC has alarmingly high obesity rates, with an overall 20% being affected. Obesity brings with it a plethora of other conditions such as heart disease, cancer, arthritis and diabetes.

Approximately 1% of the GCC population (some 420,000 people), suffer from vitiligo, a depigmentary disorder causing white patches on the skin. There is currently no available treatment that totally repigments the skin and, as a result, sufferers may also develop depressive and other psychological illnesses. Bioscience Institute is developing therapies and treatments for these conditions, which will bring much needed solutions to the health problems of people in the area.

DHCC was launched in 2002 to meet the demand for high quality, patient-centred healthcare

Dubai Healthcare City (DHCC), the world’s first ‘Free Zone’ dedicated to healthcare, was the area chosen by Bioscience for its new facility. DHCC was launched in 2002 to meet the demand for high quality, patient-centred healthcare. Today, it is home to two hospitals, more than 120 outpatient medical centres and diagnostic laboratories with more than 3,700 licensed professionals occupying 4.1m ft2 in the heart of Dubai. In addition to the general and specialised hospitals located at DHCC, two major medical complexes (housing outpatient clinics and modern analytical and diagnostic laboratories) could also offer collaboration opportunities.

Bioscience also expects to gain from health tourism. Healthcare and Tourism are the largest two industries in the world and more people are blending their health needs with their holiday needs. Cost, waiting times and quality are reasons why people seek healthcare abroad, as well as the opportunity to recuperate in a relaxing environment.

Dubai, therefore, is an obvious choice in the region. It is a leading tourist destination with all-year sunshine and world-class facilities. It is located only four hours’ flying time from one-third of the world’s population and 12 hours from 80% of the population.

MRC Systems FZE, with offices and factories in the region since 1998, was chosen by the Bioscience Institute to carry out the design and construction of the new clinic and laboratories in Dubai. Work started on this project in late 2011 and was completed about 12 months later. For the cleanroom construction Bioscience required a modular design, meeting international cleanroom standards, European GMP and a facility that was also robust, durable and flexible. Future expansion and possible relocation also had to be considered in the design.

The facility is split into two parts. The first part is where patients are received for consultations and medical procedures. In this area, materials and designs were chosen to give patients a clean, modern and relaxing environment. This area has a reception, waiting room and three patient rooms where consultations and procedures will take place.

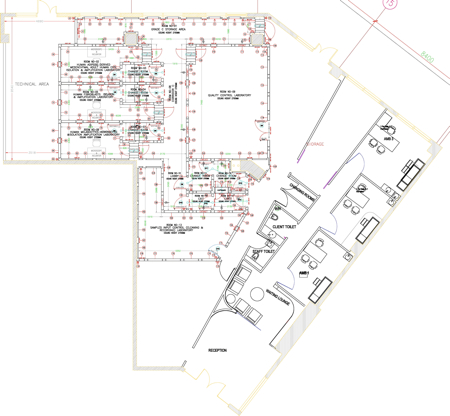

The second part of the facility has the cryopreservation area, laboratories and cleanrooms. The layout in Figure 1 shows the overall arrangements of both parts of the facility.

Figure 1: Overall floor plan of the two-part facility

The cryopreservation area was fitted with sensors operating an exhaust system designed to maintain safe concentration levels of oxygen in the air. This area has direct access to the outside to allow for the movement of nitrogen tanks in and out without passing through the facility or through the common areas of the DHCC building.

Samples obtained from patients in the adjoining patient rooms will be taken to the laboratories where tests are conducted before passing through to one of the cleanrooms for further processing. These laboratories are fitted with high quality and modern furniture. A grade A laminar flow cabinet has also been installed to provide a sterile environment for sample testing.

In the classified area, separate personnel entry and exit routes are provided. There is a double-sided garment cupboard in the wall separating these two areas. This is so that operators leaving their lab coats in the changing room going in can take them on the way out without re-entering the changing room. Both of these areas are maintained at Class 7 as defined in the cleanroom standards ISO 14644.

Each cleanroom has its own changing room and interlocked pass through box for material transfer

Once through the gowning area operators will pass through a connecting corridor maintained at Class 7 to another Class 7 area, where refrigerators and freezers are installed for cell preservation. Also through this connecting corridor operators will be able to access all three Class 5 cleanrooms. Each cleanroom has its own changing room and interlocked pass through box for material transfer.

A grade A laminar flow cabinet, an incubator (with space for more in the future), refrigerator and workstation with microscope are fitted in each cleanroom.

All Class 7 and 5 areas are installed with a continuous monitoring system tracking temperature, relative humidity, room pressure and particle count. Data are uploaded to the client website where they can be seen in real time.

Two air handling units provide air to the classified areas. One is dedicated to Class 7 areas and the other to Class 5. They are installed in a compact technical space towards the back of the cleanrooms. As in the case of the cryopreservation area, a door is fitted to this space to provide access for maintenance personnel without needing to pass through the cleanroom. The cleanroom ceiling is also designed to allow some maintenance access to services above.

The glass reinforced polyester (GRP) build system offers integral wall-to-wall and wall-to-ceiling cover

The modular system chosen for this build is manufactured from glass reinforced polyester (GRP) which has many unique properties and benefits in terms of chemical resistance, hygiene, easy maintenance and cleandown:

- Chemical resistance and zero corrosion risk

- Integral wall-to-wall and wall-to-ceiling cover

- Integral low level air extract panel

- Integral service panel for all electrical and mechanical services

- Low maintenance

- Flexibility and durability

The Bioscience Institute is preparing to receive patients in the first quarter of this year.