The fundamental objective of the International Featured Standard (IFS) Food is to establish common standards that are evaluated by a uniform system to ensure transparency throughout the global supply chain. This will enable consumers and retailers to have high levels of confidence in the goods produced as well as reducing costs and improving efficiency for suppliers.

The current version of IFS Food came into force in July 2012 and is used for auditing those companies involved in food processing or packaging of loose food products. The audit itself is carried out by an independent, certified body and consists of an in-depth analysis of both the processes and the documentation relating to the manufacturing processes that is held by the company.

In IFS Food there are 10 KO requirements, and if the auditor establishes that these requirements are not fulfilled by the company, this results in non-certification

The audit uses a scoring system to award and subtract points according to the level of compliance with each requirement. In addition, the auditor can impose a ‘KO’ (Knock-out) or a ‘Major’ non-conformity, which can subtract a percentage of the overall score. In IFS Food there are 10 KO requirements, and if the auditor establishes that these requirements are not fulfilled by the company, this results in non-certification.

One such KO requirement is the expectation to operate a robust Hazard Analysis and Critical Control Point (HACCP) system that should focus on the food handling procedures and ensure that all of the final products are safe to eat. To determine the critical control points, specific monitoring processes are required that will indicate any loss of control within a process. In addition, records of the monitoring must be maintained for a suitable period to ensure compliance.

In essence, this requires the use of temperature, pressure, conductivity, flow and other sensors to measure the process parameters and record them for future analysis. In many cases these sensors will form part of the control loop for the manufacturing process and therefore retaining this data should be a relatively simple task.

The food manufacturing company also has a responsibility to ensure that all externally sourced materials and services that have an impact on food safety or quality, conform to the required standards. This requires the food manufacturer to retain all the supporting documentation relating to the materials as evidence of compliance. All reputable manufacturers of equipment used in the food industry will provide this as a matter of course.

Clearly hygiene is of the utmost importance and so the audit also scrutinises the cleaning and disinfection processes

Clearly hygiene is of the utmost importance within the food industry and so the audit also scrutinises the cleaning and disinfection processes to ensure that they provide effective coverage. For many manufacturers this will involve clean-in-place (CIP) methods to ensure that the manufacturing facility is safe. To provide evidence of the effectiveness of these processes, it may be necessary to have additional conductivity and flow sensors in place to monitor and record each procedure.

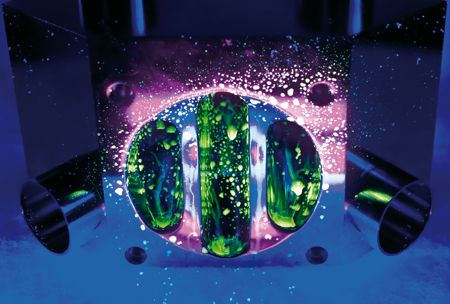

Bürkert is able to test cleaning cycles and provide 100% reliability on the flow properties and cleanability of a complete valve assembly by using a riboflavin test rig. In hygienic applications where CIP is operated, it is essential to be able to ensure the cleaning cycle is both effective and efficient; criteria that can be completely fulfilled and demonstrated by Bürkert.

Visualisation of the fluorescent effect of riboflavin under UV light on a valve interface component in a test rig

The ever-increasing demands of consumers and the rising liabilities of food retailers have led to the increased requirement for a uniform quality assurance scheme that will satisfy all stakeholders. The IFS Food Standard details the exact requirements of those wishing to be certified under its audit process, which at first glance can appear daunting. However, by maintaining existing systems and seeking expert advice, it is possible to attain the required standards.

Bürkert has experience in designing components and complete process lines that are optimised for hygienic conditions, using premium materials and the latest design techniques. It can deliver highly efficient processes, exceeding current hygiene legislation. The company has developed a wide range of control valves, pressure, conductivity and flow sensors, all of which can be used to develop an efficient and accurate process control system, complying with the monitoring and data recording requirements of the latest standard.